Solar Strut Profile Roll Forming Line Revolutionizing Solar Panel Mounting Solutions

In recent years, the surge in renewable energy sources has ushered in a new era of technological advancements aimed at optimizing energy production. Among these innovations, the solar strut profile roll forming line has emerged as a pivotal player in the solar energy sector, offering a streamlined solution for manufacturing mounting structures necessary for solar panel installations.

Understanding Roll Forming Technology

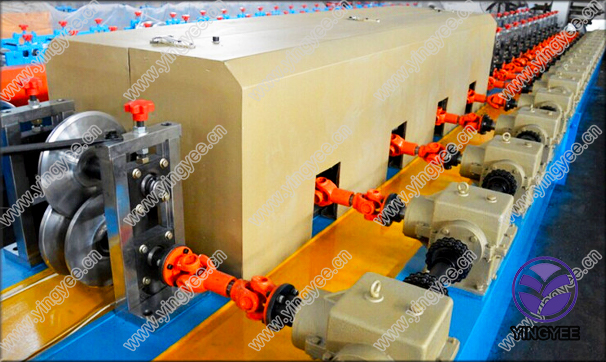

Roll forming is a continuous bending operation that creates long parts with constant cross-sections. The process involves feeding metal sheets through a series of rollers that progressively shape the material. This technique is particularly beneficial for producing consistent and uniform profiles, making it ideal for components like struts, which are instrumental in supporting solar panels.

Applications in Solar Energy

The mounting structures produced using solar strut profile roll forming lines are critical for optimizing the efficiency and durability of solar panel installations. These struts serve as the framework that holds solar panels in place, ensuring that they are properly aligned to capture maximum sunlight. The strength and resilience of roll-formed profiles contribute significantly to the overall performance of solar energy systems, especially in regions with adverse weather conditions.

Advantages of Solar Strut Profile Roll Forming Lines

1. Efficiency and Output One of the most significant advantages of a roll forming line is its high production efficiency. Once set up, the machine can operate continuously, producing large volumes of struts in relatively short periods. This high output capability meets the growing demand for solar mounting solutions as more consumers and businesses switch to solar energy.

2. Precision and Consistency Roll forming provides a level of precision that is difficult to achieve with other manufacturing methods. Each strut produced maintains uniform dimensions and weight, which is essential for ensuring quality and reliability in solar installations. The consistent profile leads to easier assembly and reduced issues in the field, making the installation process smoother.

3. Material Utilization The roll forming process is material-efficient, as it minimizes waste through optimal shaping techniques. Materials such as galvanized steel or aluminum – favored for their corrosion resistance – can be employed, further enhancing the longevity of the solar mounting structures.

4. Versatility Solar struts can be designed to meet specific requirements based on the installation environment. Whether for roof-mounted systems, ground-mounted arrays, or other configurations, roll forming lines can produce a variety of profiles tailored to diverse applications.

5. Cost-Effectiveness While initial investments in roll forming equipment can be substantial, the long-term savings are considerable. Reduced material waste, labor costs associated with quick assembly, and fewer on-site adjustments lead to lower overall project costs.

Future Prospects

As the demand for renewable energy continues to rise, advancements in roll forming technology are expected to evolve, increasing the efficiency and capabilities of solar strut production lines. Innovations such as automation and integration with smart technologies can further enhance productivity while maintaining high quality standards.

Conclusion

The solar strut profile roll forming line represents a critical component of modern solar energy infrastructure. By providing efficient, precise, and cost-effective solutions for manufacturing solar panel mounting structures, this technology is playing an essential role in making solar energy more accessible and sustainable. As we move towards a greener future, innovations in roll forming will undoubtedly contribute to the ongoing growth of the solar industry, helping to pave the way for a more sustainable planet.