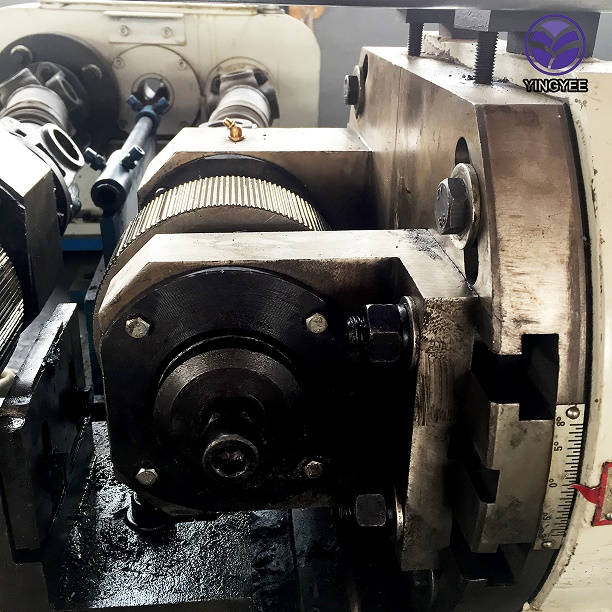

The pipe thread rolling machine stands as a cornerstone in the realm of industrial manufacturing, bringing precision and efficiency to the threading process. These machines are essential in industries where the integrity of pipe connections is crucial, such as in plumbing, oil and gas, and large-scale construction projects. Their design and function cater to producing robust threads that can withstand high pressure and varying environmental conditions.

At the heart of a pipe thread rolling machine is its ability to create seamless threads without compromising the structural integrity of the pipe itself. Unlike traditional cutting methods, thread rolling strengthens the material by compressing the metal, creating a thread that is often more durable and resistant to damage. This characteristic is invaluable in industries where reliability and longevity of connections are a priority.

Engineers and manufacturers emphasize the machine’s efficiency and the consistent quality it delivers. Compared to manual threading or outdated machinery, modern pipe thread rolling machines are equipped with advanced features that significantly reduce setup time and production errors. These machines are typically integrated with computer numerical control (CNC) systems, allowing operators to produce threading with precision, often translating into material cost savings and minimized waste.

The versatility of pipe thread rolling machines is another aspect that underscores their importance in industrial settings. They can accommodate various pipe sizes and materials, ranging from softer metals like aluminum to harder ones like stainless steel. This flexibility ensures that regardless of the project's requirements, manufacturers have the capability to deliver suitable products without the need for significant changes in their setup.

Furthermore, safety and ease of use are pivotal elements manufacturers focus on. Modern machines are designed with user-friendly interfaces that require minimal training for operators. This aspect not only enhances productivity but also reduces the likelihood of operational mishaps, which can be costly and hazardous. Manufacturers often provide extensive training and support, ensuring operators are fully capable of maximizing the machine's capabilities.

In technology and innovation, the latest models of pipe thread rolling machines embrace IoT and AI, aligning them with Industry 4.0 standards. These enhancements enable real-time monitoring and predictive maintenance, substantially reducing downtime and maintaining optimal performance levels. Such innovations extend the machine's life and ensure that production remains uninterrupted, even under the highest demand.

Trust in a pipe thread rolling machine is built through thorough testing and adherence to industry standards. Reputable manufacturers ensure their machines undergo rigorous testing and quality control measures. Certifications from recognized bodies are often showcased, providing buyers with the assurance of the machine’s performance and compliance with international standards.

For industrial professionals seeking a reliable pipe threading solution, selecting the right machine involves understanding specific project requirements and evaluating machine capabilities accordingly. Experts often recommend engaging with suppliers who offer customization options and post-purchase support, crucial factors that can significantly influence the machine’s integration into existing production lines.

In conclusion, a pipe thread rolling machine is not merely a piece of equipment; it is an investment towards precision, efficiency, and reliability. By embracing modern technologies and maintaining stringent quality standards, these machines continue to be indispensable in sectors demanding robust pipe connections.