Understanding Sheet Metal Cut to Length Machines

Sheet metal cut to length machines are essential pieces of equipment in the manufacturing and fabrication industries

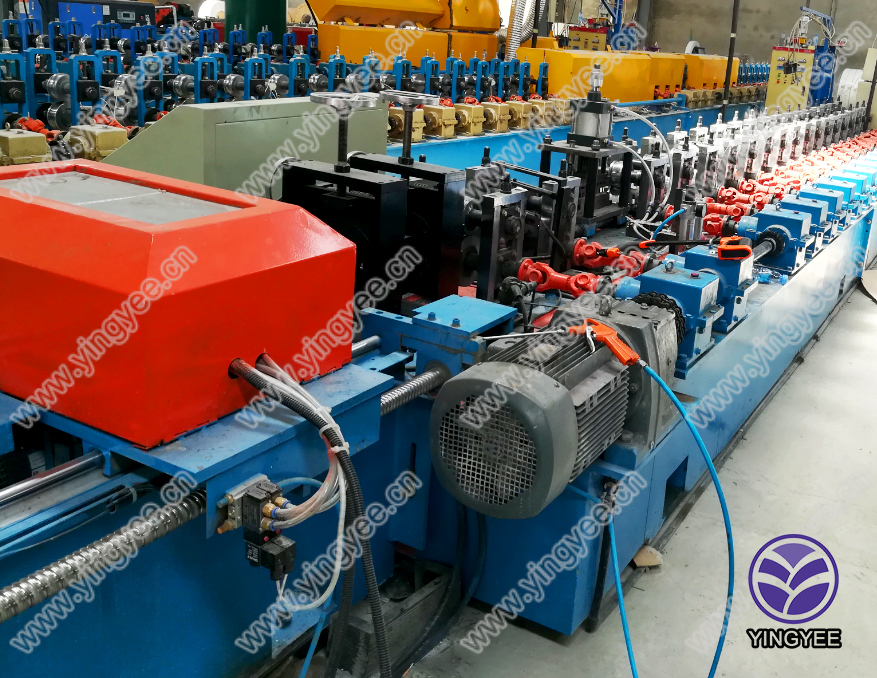

. These machines are designed to streamline the process of cutting large rolls or sheets of metal into specific lengths, making them a vital component for various applications ranging from automotive to aerospace, construction, and even consumer goods.The working principle of a cut to length machine is quite straightforward. It typically begins with a large coil of sheet metal, which is unwound and fed into the machine. As the metal rolls through, it is measured accurately using advanced sensors and controls. Once the desired length is reached, the machine executes a cutting action, which can be performed using shear blades or lasers. The resulting pieces are then stacked systematically for further processing or shipping.

One of the most significant advantages of using a cut to length machine is its efficiency. In manual processes, cutting sheets can be a labor-intensive task and often results in varied lengths and inconsistent quality. Automated cut to length machines help eliminate human error, providing more precise cuts and enhancing overall productivity. This automation enables companies to speed up their operations significantly while also reducing waste, as the machines are designed to maximize material usage.

Moreover, modern sheet metal cut to length machines come with advanced features that allow for greater versatility. Many machines are equipped with programmable controls, enabling users to store multiple cutting lengths and settings for different projects. This flexibility is particularly beneficial in industries that demand a quick turnaround on orders or where manufacturers deal with a wide variety of metal grades and thicknesses. With the capability to adjust settings on the fly, operators can easily switch from one job to another without extensive downtime.

Safety is another crucial aspect of operating cut to length machines. These machines are typically designed with protective features to ensure the safety of operators. Emergency stop buttons, guard rails, and safety interlocks are common safety measures that help prevent accidents during operation. Furthermore, operators are usually required to undergo specific training to operate these machines safely and effectively, ensuring that they are aware of potential hazards and the best practices to mitigate them.

In addition to efficiency and safety, cut to length machines contribute to the overall quality of the finished product. Consistent cutting lengths and clean edges are crucial in many applications, particularly in industries where precision is paramount. High-quality cut pieces reduce the need for additional finishing processes, saving time and labor costs while enhancing the final product's quality.

In conclusion, sheet metal cut to length machines play a crucial role in modern manufacturing. Their ability to automate the cutting process increases efficiency, reduces waste, and improves product quality. With advances in technology, these machines continue to evolve, offering manufacturers enhanced versatility and capabilities that meet the ever-changing demands of the industry. As the need for precision engineering and rapid production grows, the significance of cut to length machines in the manufacturing process will undoubtedly continue to rise, making them indispensable tools for businesses across various sectors.