The Stainless Steel Tube Mill A Pillar of Modern Manufacturing

In the realm of manufacturing, stainless steel tube mills play an indispensable role, contributing significantly to various industries including construction, automotive, and medical sectors. The production of stainless steel tubes, known for their corrosion resistance and durability, has become a cornerstone of modern infrastructure and technology.

Understanding Stainless Steel Tube Mills

Stainless steel tube mills are specialized facilities designed for the manufacturing of stainless steel tubes through a series of intricate processes. The main raw material, stainless steel, is an alloy of iron, chromium, and sometimes nickel, which offers unmatched resistance to rust and tarnish, making it ideal for a diverse range of applications.

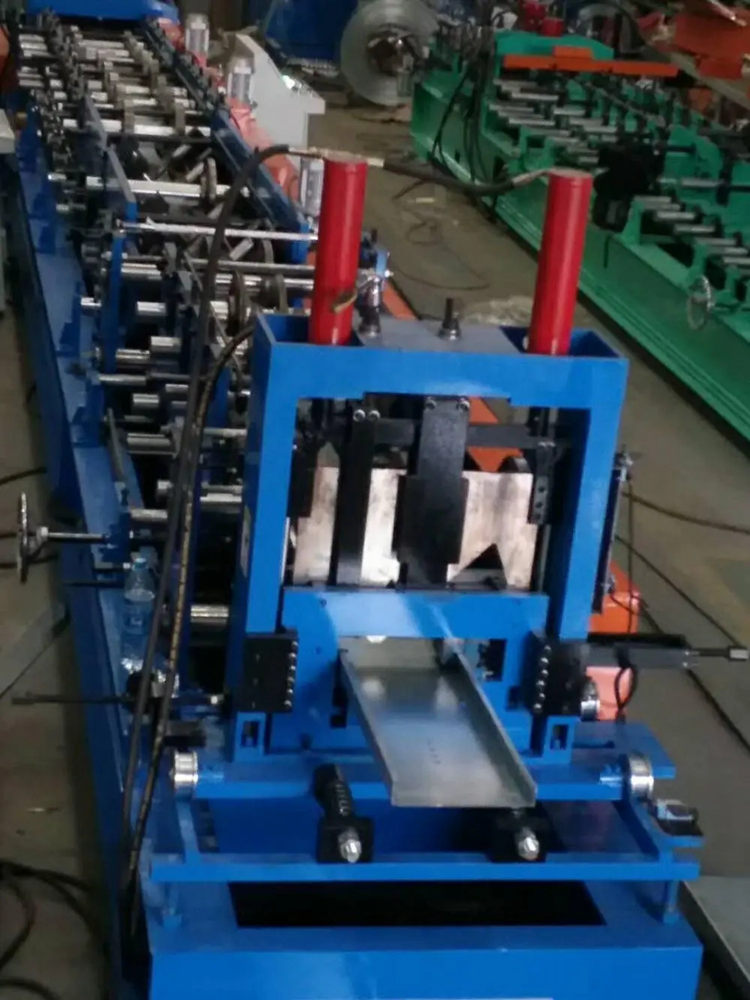

The tube-making process typically begins with the forming of a flat strip of stainless steel, which is then fed into the mill. In the mill, the strip undergoes a series of shaping and welding processes. The most common method used is the Electric Resistance Welding (ERW) technique, where the edges of the steel are heated and fused together under pressure, forming a seamless tube. This method not only enhances the structural integrity of the tube but also allows for high production speeds.

Applications and Advantages of Stainless Steel Tubes

Stainless steel tubes are utilized in a plethora of applications. In the construction industry, they are used for structural purposes, as handrails, and in framing systems due to their strength and aesthetic appeal. In the automotive sector, stainless steel tubes are essential components for exhaust systems, fuel lines, and other parts where heat and corrosion resistance are crucial.

One of the significant advantages of using stainless steel tubes is their durability. Unlike traditional materials, stainless steel requires minimal maintenance and can last decades without succumbing to wear and tear. Moreover, these tubes are highly adaptable, available in various sizes, shapes, and finishes, catering to the specific needs of different industries.

The Importance of Technology in Tube Manufacturing

With the advent of advanced manufacturing technologies, the efficiency and quality of stainless steel tube mills have improved drastically. Automated systems and computerized controls minimize human error, maintain consistency, and enhance productivity. Furthermore, innovations such as laser welding technology and precision cutting tools have revolutionized the manufacturing process, allowing for tighter tolerances and better quality assurance.

Quality control is paramount in the production of stainless steel tubes. Manufacturers are increasingly employing non-destructive testing methods such as ultrasonic and radiographic testing to ensure that their products meet rigorous safety and performance standards. This commitment to quality not only satisfies regulatory requirements but also builds trust with consumers and industries that rely on these products.

Conclusion

In conclusion, stainless steel tube mills are crucial to the contemporary manufacturing landscape. Their ability to produce high-quality, durable, and versatile stainless steel tubes makes them integral to several industries. As technology continues to evolve, these mills will undoubtedly adopt new methods and practices, further enhancing their efficiency and production capabilities. In an age where sustainability and reliability are paramount, stainless steel, with its unmatched properties, will continue to be a preferred material for manufacturers around the globe. The future of tube manufacturing is bright, and the potential for innovation is limitless.