Understanding Down Pipe Roll Forming Machines

Down pipe roll forming machines are specialized equipment designed to manufacture downpipes—essential components in rainwater drainage systems for buildings. These machines utilize a continuous roll forming process, allowing for efficient and precise production of metal profiles that are crucial for directing rainwater away from roofs and foundations.

What is a Down Pipe Roll Forming Machine?

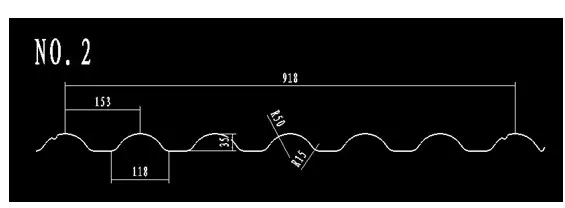

A down pipe roll forming machine works by feeding metal sheets, typically made from galvanized steel, aluminum, or stainless steel, through a series of rollers. These rollers progressively shape the metal into the desired profile of a downpipe. The process is automated, which increases production speed and minimizes the potential for errors. The resulting downpipes can vary in size and configuration based on the specifications required for different architectural designs.

Key Benefits of Using Roll Forming Machines

One of the primary advantages of using a down pipe roll forming machine is the high level of efficiency it offers. This method enables manufacturers to produce long lengths of downpipe in a continuous process, reducing waste and saving on material costs. Additionally, the consistent quality of the finished product leads to fewer reworks, ultimately enhancing the overall productivity of the manufacturing line.

Furthermore, down pipe roll forming machines can be easily customized to meet specific production needs. Manufacturers can adjust the machine settings to create different profiles, widths, and thicknesses of downpipes. This flexibility is particularly beneficial for companies that aim to cater to diverse customer requirements or those that work on bespoke projects.

Maintenance and Operational Considerations

While down pipe roll forming machines are designed for durability and longevity, regular maintenance is crucial to ensure optimal performance. Operators need to pay attention to lubrication needs, check for wear and tear on the rollers, and keep the machine clean to prevent debris accumulation that could affect the forming process. Training staff to operate and troubleshoot the machinery effectively can also enhance safety and efficiency on the production floor.

Conclusion

In summary, down pipe roll forming machines play a vital role in the construction industry by offering an effective solution for producing reliable, high-quality downpipes. With their efficiency, customizability, and ease of operation, these machines significantly contribute to the smooth functioning of building drainage systems. As technology continues to improve, it is likely that these machines will incorporate even more sophisticated features, further enhancing their productivity and integration into modern manufacturing processes. The advancement of these machines reflects the industry's ongoing commitment to efficiency and quality in construction and building maintenance.