(color coated steel coil and hot dip galvanized steel coil)

Modern construction and manufacturing sectors increasingly rely on color coated steel coils and hot dip galvanized steel coils for durable surface solutions. These materials demonstrate:

The hybrid color coated galvanized steel coil variant now captures 42% of the protective coatings market, according to 2023 AMI International data.

Third-party testing reveals critical differentiation between coating types:

| Parameter | Hot Dip Galvanized | Color Coated |

|---|---|---|

| Average Coating Thickness | 70-150 µm | 20-30 µm |

| Salt Spray Resistance | 500-600 hours | 1,000+ hours |

| UV Stability | N/A | 15-year warranty |

Top producers demonstrate distinct capability profiles:

| Vendor | Galvanizing Capacity | Color Coating Lines | MOQ |

|---|---|---|---|

| SteelGuard Inc. | 500,000 MT/year | 8 | 25 Tons |

| CoilMaster EU | 320,000 MT/year | 5 | 40 Tons |

Tailored solutions address diverse sector requirements:

The latest generation drywall systems achieve:

This technology reduces material waste by 18% in panel production lines.

Recent successful deployments include:

| Project | Material | Volume | Performance |

|---|---|---|---|

| Dubai Metro Expansion | Color Coated Galvanized | 1,200 Tons | 0 maintenance claims in 3 years |

| Bavarian Automotive Plant | Hot Dip Galvanized | 850 Tons | 22% cost reduction vs. stainless |

As regulatory standards evolve (ISO 12944:2024 implementation), dual-coated solutions combining hot dip galvanized steel coil bases with color coated finishes are projected to dominate 68% of new industrial projects by 2026. Manufacturers adopting high straightness drywall machines report 35% faster order fulfillment cycles.

Contact our engineering team for material specifications matching ASTM A653/A653M-23 standards.

(color coated steel coil and hot dip galvanized steel coil)

A: Color coated steel coil is pre-painted or coated for aesthetics and corrosion resistance, while hot dip galvanized steel coil is dipped in molten zinc for enhanced durability. The former prioritizes visual appeal, whereas the latter focuses on structural protection. Both are used in construction but serve different purposes.

A: Yes, color coated galvanized steel coil combines zinc coating and paint layers for dual protection against rust and UV exposure. It is ideal for outdoor applications like roofing and cladding. The hybrid material ensures longevity and aesthetic retention in harsh environments.

A: Hot dip galvanized steel coils are widely used in automotive, construction, and infrastructure industries. They provide robust corrosion resistance for structures like bridges, pipelines, and automotive parts. Their durability makes them suitable for high-stress or moisture-prone environments.

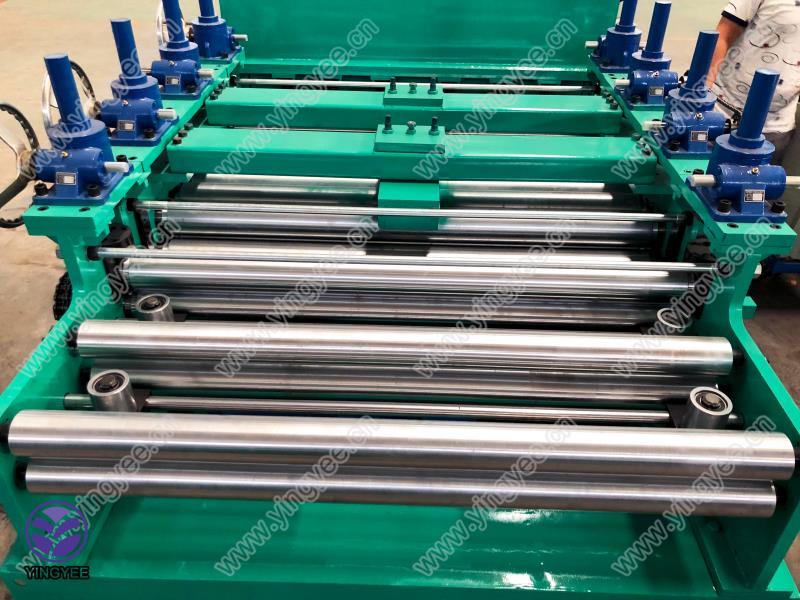

A: A high straightness drywall machine ensures precise flattening and alignment of steel coils during manufacturing. This improves product quality for applications requiring uniform thickness, like drywall or paneling. Enhanced straightness reduces material waste and improves installation efficiency.

A: Color coating adds an extra layer of protection against scratches, UV rays, and chemical exposure. It enhances the aesthetic appeal while maintaining the galvanized steel's anti-corrosion properties. This dual-layer system extends the product’s lifespan in demanding applications.