The Evolution and Importance of Downspout Forming Machines

In the realm of construction and building maintenance, downspout forming machines play a crucial role in ensuring effective drainage systems. These machines are specifically designed to fabricate downspouts, which are vertical pipes used to channel rainwater from roofs to the ground, preventing water damage to buildings. The significance of downspout forming machines cannot be overstated, as they contribute to the efficiency and sustainability of modern architecture.

What is a Downspout Forming Machine?

A downspout forming machine is an industrial piece of equipment that shapes metal sheets into downspout profiles. Typically made from galvanized steel or aluminum, these machines employ advanced technology to achieve precise dimensions and consistent quality in the manufactured products. The machines can shape the metal into various configuration styles—such as rectangular or circular profiles—depending on the specific needs of a building or project.

The Process of Downspout Formation

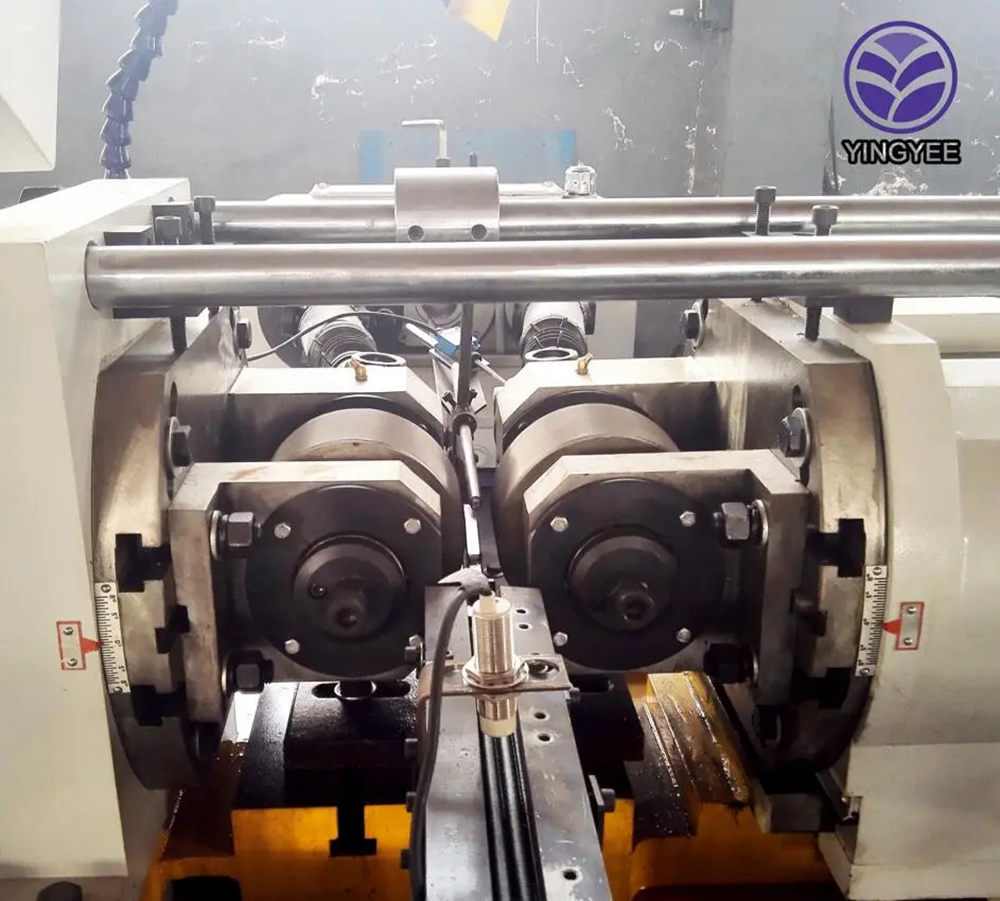

The manufacturing process starts with the selection of raw materials, generally in the form of large coils of sheet metal. The coils are loaded into the forming machine, which unwinds the material and passes it through a series of rollers. These rollers gradually shape the metal into the desired downspout profile. After the initial forming, the machine often includes stations for cutting to length, punching holes for fastening, and adding any necessary bends or angles to accommodate roof designs.

One of the notable advancements in downspout forming machines is the integration of computer numerical control (CNC) technology. This allows operators to input specific design parameters, ensuring that every downspout produced is tailored to the exact specifications required for the installation. This level of customization not only enhances efficiency but also minimizes waste, making the entire process more environmentally friendly.

Benefits of Using Downspout Forming Machines

The use of downspout forming machines presents several advantages over traditional manufacturing methods. First and foremost, they offer speed and efficiency. The automated nature of these machines significantly reduces labor costs and production time, allowing companies to fulfill large orders promptly.

Additionally, the precision offered by modern downspout forming machines ensures consistent product quality. This is crucial for construction projects, where even minor deviations in measurements can lead to costly issues during installation or, worse, water damage post-construction. By using a forming machine, manufacturers can maintain high standards and provide products that fit seamlessly into drainage systems.

Moreover, the versatility of downspout forming machines enables manufacturers to cater to a diverse client base. Whether for residential properties, commercial buildings, or industrial projects, these machines can adapt to produce different sizes and shapes, making them an invaluable asset for manufacturers in the building industry.

Environmental Considerations

With growing concerns about sustainable practices, downspout forming machines also contribute to environmental protection. By allowing for the efficient use of materials and minimizing waste during production, these machines support an eco-friendlier approach to construction. Furthermore, by facilitating effective rainwater drainage, well-designed downspouts help to reduce flooding and erosion, safeguarding not just the buildings they protect, but the surrounding environment as well.

Conclusion

In summary, downspout forming machines represent a critical innovation in the construction industry. Their ability to efficiently and accurately produce high-quality downspouts makes them indispensable in modern building practices. As technology continues to evolve, we can expect these machines to become even more sophisticated, further enhancing their role in sustainable construction and maintenance solutions.