The Production Line of Color Stone Coated Roof Tiles A Comprehensive Overview

In recent years, the roofing industry has witnessed a significant transformation with the introduction of color stone coated roof tiles. These innovative tiles not only enhance the aesthetic appeal of buildings but also provide exceptional durability and insulation. The production line for these tiles is a meticulous process, integrating advanced technology and quality materials to ensure that every tile meets high industry standards.

Raw Material Selection

The production of color stone coated roof tiles begins with the careful selection of raw materials. The primary components include a metal base, typically made from high-quality steel or aluminum, which serves as the skeleton of the tile. This is coupled with a layer of acrylic resin, which provides adhesive properties, ensuring that the stone coating adheres effectively.

The color stone coating itself is comprised of natural stone granules, which are not only visually appealing but also contribute to the tiles’ resistance against various weather conditions. The stones are available in a spectrum of colors and textures, allowing for customization according to architectural preferences. This raw material selection is critical, as it directly impacts both the performance and longevity of the finished product.

Production Process Overview

The production line of color stone coated roof tiles can be broken down into several key stages

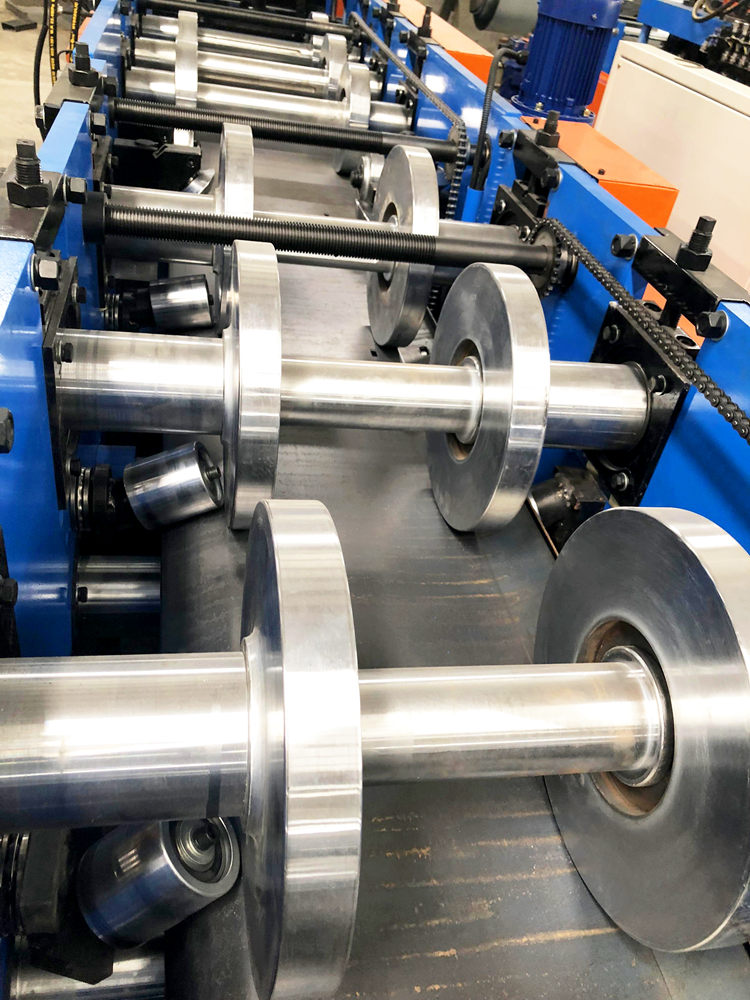

. Each stage is designed to ensure efficiency and high-quality output.1. Metal Base Preparation The process begins with the preparation of the metal sheet, which is cut into the required dimensions for the tiles. The metal is then treated with a corrosion-resistant coating to enhance durability and extend its life cycle.

2. Application of Acrylic Resin Once the metal base is ready, a layer of acrylic resin is applied uniformly across the surface. This layer plays a crucial role in providing additional protection and adhesion for the stone coating that follows.

3. Stone Coating Application The application of the stone granules is a precision step in the production process. A mixture of colored stone granules is evenly spread over the resin-coated tiles. This step requires careful calibration of the granule size and distribution to ensure a uniform finish.

4. Baking and Curing After the stone coating is applied, the tiles undergo a baking process. This step not only helps in curing the resin but also binds the stone granules securely to the metal base, ensuring that they are resistant to peeling, fading, or damage from the elements.

5. Quality Control Quality assurance is an integral part of the production line. Each tile is subjected to rigorous testing, including checks for strength, water resistance, and color consistency. Tiles that do not meet the specified standards are rejected or recycled, ensuring that only the best products reach the market.

6. Packaging and Distribution Once the tiles pass quality control, they are neatly packaged, ready for distribution. The packaging process is designed to protect the tiles during transportation and handling, minimizing the risk of damage before they reach builders and homeowners.

Conclusion

The production line of color stone coated roof tiles is a testament to the integration of modern technology and traditional craftsmanship. As the demand for aesthetically pleasing and durable roofing solutions continues to rise, the process of creating these tiles remains a pivotal aspect of the construction industry. With their unparalleled advantages, such as longevity, weather resistance, and customizable appearances, color stone coated roof tiles are set to redefine roofing standards and enhance the architectural beauty of buildings for years to come. Through meticulous production processes and quality materials, manufacturers ensure that these tiles not only meet but exceed the expectations of consumers and builders alike.