Understanding the Standing Seam Forming Machine A Key Innovation in Metal Roofing

In recent years, standing seam roofing systems have gained significant popularity due to their durability, aesthetic appeal, and energy efficiency. At the heart of this innovative roofing solution lies the standing seam forming machine, a crucial piece of equipment used in the production of standing seam metal panels. This article will explore the workings of standing seam forming machines, their benefits, and their impact on the roofing industry.

What is a Standing Seam Forming Machine?

A standing seam forming machine is a specialized piece of machinery designed to fabricate metal roofing panels with raised seams. These seams are typically vertical and run the entire length of the roof, allowing water to flow off the surfaces without penetrating the joints. The machine operates by transforming flat sheets of metal, usually pre-painted or coated steel or aluminum, into panels with specific profiles and standing seams.

The Working Process

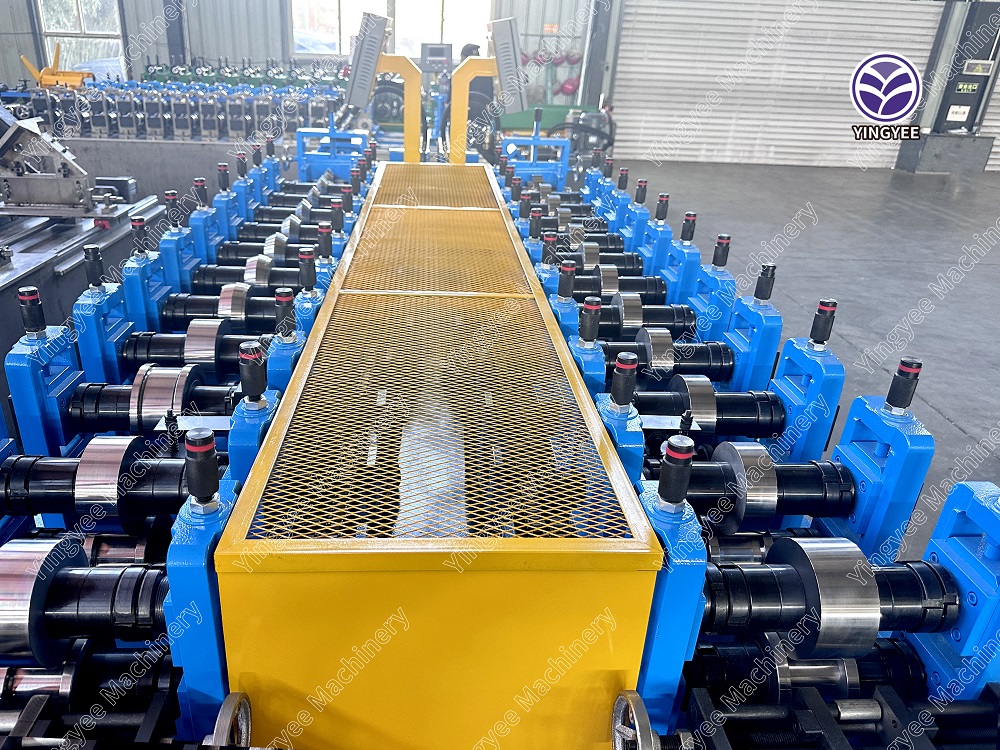

The process begins with feeding flat metal sheets into the forming machine. These sheets are unwound from coils and cut to the desired length. The machine uses a series of rollers to shape the metal into a standing seam profile, which is defined by its unique ribs and grooves. This shaping process ensures that the seams are sufficiently raised to provide effective water drainage.

The standing seam forming machine operates under high precision, with adjustments made for different panel widths and heights. As the machine forms the panels, it also incorporates features such as clip slots and interlocks, which facilitate easy installation and enhance the structural integrity of the roof. Once the panels are formed, they can be further processed, including cutting to size and punching holes for fasteners.

Benefits of Using Standing Seam Forming Machines

1. Efficiency One of the primary advantages of standing seam forming machines is their ability to produce panels quickly. This efficiency allows manufacturers to meet increasing demand while maintaining consistent quality. The automation inherent in these machines reduces labor costs and minimizes human error during production.

2. Customization Standing seam forming machines can be easily adjusted to create custom panel lengths, widths, and profiles. This flexibility allows roofing contractors to meet specific project requirements, such as varied roof slopes or unique design aesthetics.

3. Durability The standing seam panels produced by these machines are robust and can withstand harsh weather conditions, including high winds and heavy snowfall. The raised seams also help minimize the risk of leaks, ensuring long-lasting performance for the roof.

4. Energy Efficiency Many standing seam roofing systems come with reflective coatings that reduce heat absorption, leading to lower energy costs. Standing seam forming machines can produce panels in various colors and finishes to enhance the energy efficiency of buildings.

Impact on the Roofing Industry

The introduction of standing seam forming machines has significantly impacted the metal roofing industry. They have enabled manufacturers to meet the growing demand for high-quality metal roofing while keeping pace with advancements in construction methods and aesthetic preferences.

Moreover, the use of standing seam materials promotes sustainability. Many metal panels are made from recycled materials and are fully recyclable at the end of their life cycle. This eco-friendly aspect aligns with the global shift towards sustainable building practices, making standing seam roofs an attractive option for environmentally conscious consumers.

Conclusion

In conclusion, standing seam forming machines play a vital role in modern roofing applications. By enhancing efficiency, customization, durability, and energy performance, they have revolutionized the production of standing seam roofing systems. As technology continues to advance, we can expect even greater innovations in this arena, further solidifying the standing seam roofing system's place as a leading choice for both residential and commercial buildings. Whether you are a contractor, a manufacturer, or a homeowner, understanding the significance of these machines is crucial in appreciating the quality and advantages they bring to the roofing industry.