The Roof Sheet Forming Machine Revolutionizing the Construction Industry

In the modern world where innovation drives efficiency and productivity, the roof sheet forming machine stands out as a vital piece of equipment in the construction and manufacturing sectors. This advanced machinery is designed to streamline the production of roof sheets, offering significant benefits over traditional manufacturing methods. In this article, we will explore the workings, advantages, and impact of roof sheet forming machines on the industry.

Understanding Roof Sheet Forming Machines

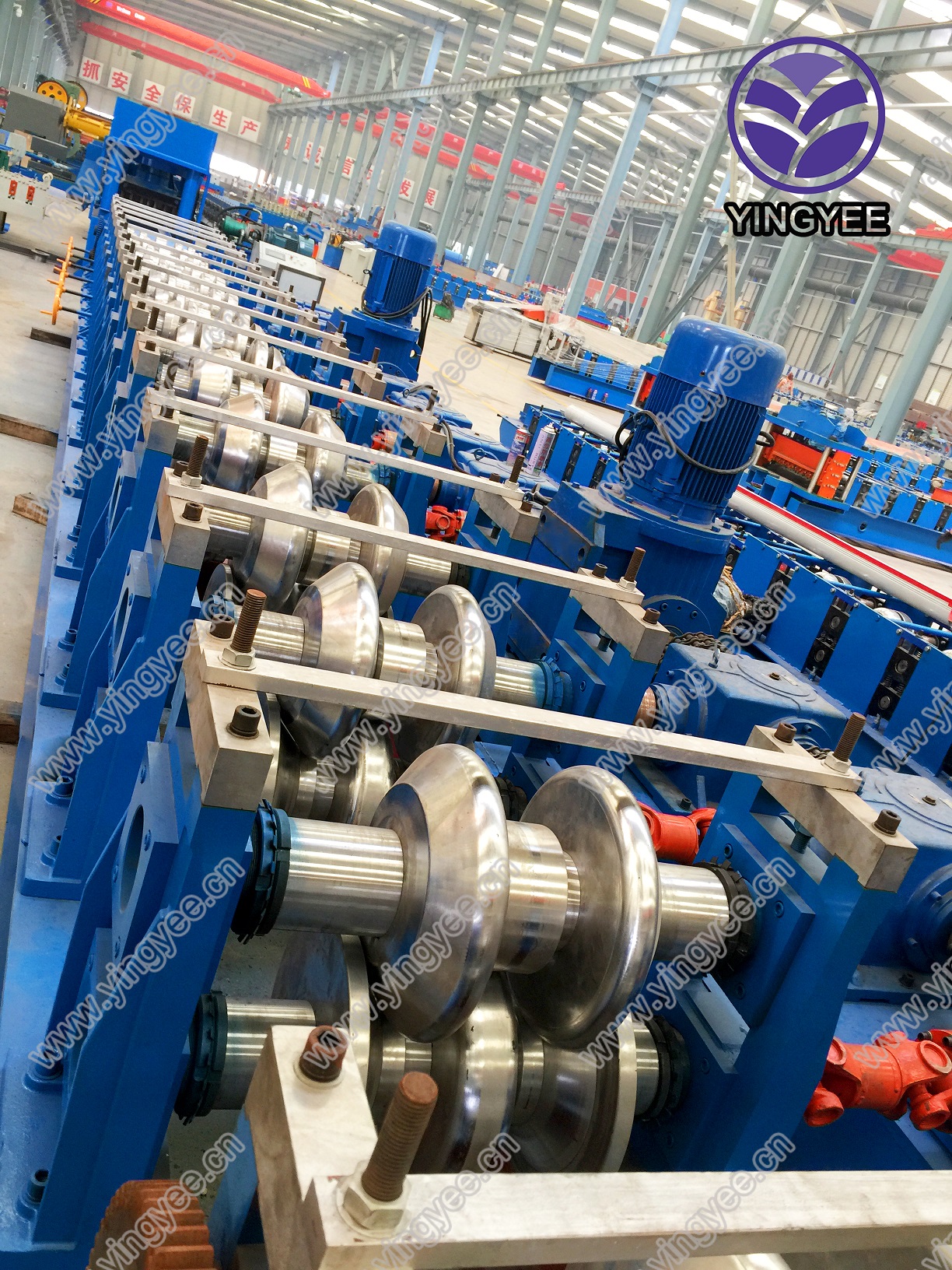

The roof sheet forming machine is an automated system responsible for producing metal sheets that are commonly used in roofing applications. These machines operate by feeding metal coils into a series of rollers, which shape the metal into specific profiles, such as corrugated or trapezoidal sheets. The process typically involves several stages, including decoiling, forming, cutting, and stacking, ensuring a seamless transition from raw material to finished product.

One of the key features of these machines is their ability to produce highly uniform and precise sheets at a high speed. This not only reduces labor costs but also minimizes material waste, making the production process more sustainable. The machines can be customized to accommodate various sheet sizes and thicknesses, catering to the diverse needs of the construction industry.

Advantages of Roof Sheet Forming Machines

1. Efficiency and Speed Modern roof sheet forming machines are designed for high-speed production. They can produce large quantities of sheets in a short amount of time, which is crucial for meeting the demands of ongoing construction projects.

2. Cost-Effectiveness By automating the production process, these machines significantly reduce labor costs associated with manual manufacturing. Additionally, the precision in cutting and shaping leads to less material wastage, further decreasing overall production costs.

3. Quality and Durability The roof sheets produced by these machines are known for their high quality. The consistent manufacturing process ensures that each sheet maintains its structural integrity and durability, which is essential for any roofing application.

4. Versatility Roof sheet forming machines can be configured to create a wide variety of profiles and dimensions. This flexibility allows manufacturers to cater to different customer needs, from residential housing to large industrial buildings.

5. Ease of Operation Most machines come equipped with user-friendly interfaces, enabling operators to manage the production process with minimal training. This accessibility contributes to an increase in overall productivity.

Impact on the Construction Industry

The introduction of roof sheet forming machines has significantly impacted the construction industry. With their ability to produce high-quality, customized roof sheets quickly and efficiently, they have transformed the way roofing materials are manufactured and supplied. This has led to faster construction times, reducing project delays and boosting overall productivity.

Moreover, the increased availability of cost-effective roofing solutions has made it easier for builders to complete projects within budget, leading to a more competitive market. As the construction industry continues to grow, the demand for reliable and efficient roofing solutions, such as those provided by roof sheet forming machines, will only increase.

Conclusion

In summary, the roof sheet forming machine represents a significant technological advancement in the construction and manufacturing industries. With its ability to produce high-quality roofing materials efficiently and cost-effectively, this machinery is playing an essential role in shaping the future of construction. As businesses continue to seek ways to improve operational efficiency and sustainability, roof sheet forming machines will undoubtedly remain a pivotal part of their production processes, driving innovation and growth in the industry.