The Art and Science of Knudson Roll Forming

Knudson Roll Forming is a specialized manufacturing process that involves shaping metal into desired profiles through a series of rollers. This technique is widely used in various industries due to its ability to produce complex shapes with high accuracy and efficiency. Understanding the intricacies of roll forming can provide insights into its advantages, applications, and innovations.

What is Roll Forming?

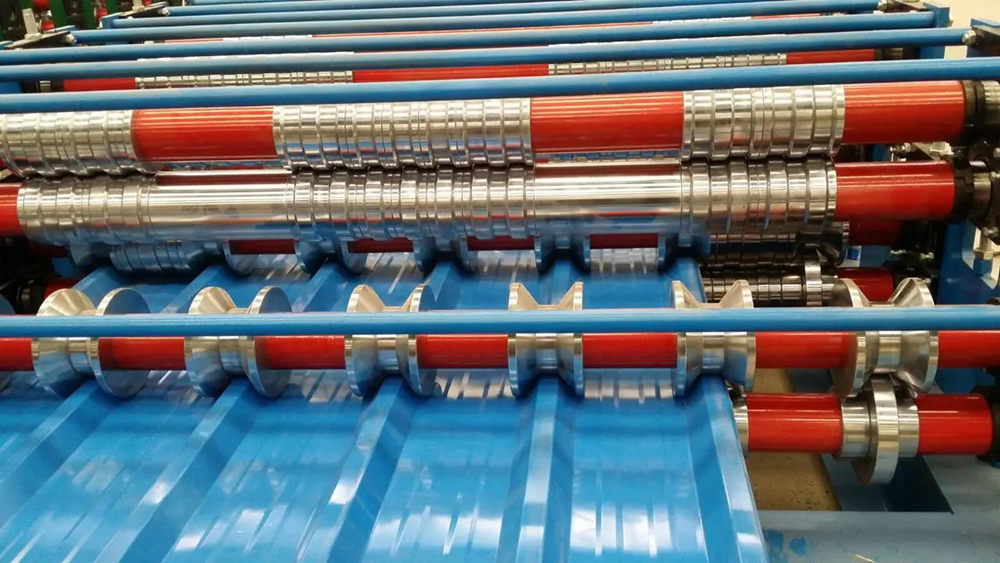

Roll forming is a continuous bending operation in which a long strip of metal is passed through a sequence of rollers, each designed to progressively shape the metal into a specific profile. The process starts with a flat sheet or coil of metal, which is fed into the roll forming machine. As the metal passes through each set of rollers, it undergoes deformation, eventually taking on the desired cross-sectional shape.

The Knudson Process

Named after the company that pioneered many advancements in roll forming technology, Knudson Roll Forming utilizes both standard and custom-designed roller systems. This approach caters to the diverse needs of its clients, ranging from construction materials to automotive components. Knudson's commitment to precision and quality guarantees that every piece produced meets stringent standards.

One of the hallmarks of Knudson Roll Forming is its emphasis on efficiency. The process allows for high production rates with minimal material waste, which is increasingly important in today’s eco-conscious manufacturing landscape. Additionally, the precision of roll forming promotes excellent dimensional accuracy, reducing the need for secondary processes such as trimming or machining.

Applications in Different Industries

The flexibility of Knudson Roll Forming enables its application in various sectors. For instance, in the construction industry, roll-formed steel is commonly used for framing, roofing, and siding. The ability to produce long lengths without seams makes it an ideal choice for structural components that require strength and durability.

In the automotive industry, roll forming plays a crucial role in creating components like chassis and support structures. Lightweight, yet strong materials shaped through this process contribute to overall vehicle efficiency, enhancing fuel economy without compromising safety.

Moreover, electric and electronic industries leverage roll forming to manufacture complex and precision-engineered parts such as brackets and housings, where accuracy is paramount.

Innovations and Future Trends

As technology evolves, so too does the roll forming process. Innovations such as automation and computer numerical control (CNC) systems are streamlining operations, further enhancing the efficiency and accuracy of production. These advancements allow for quick adjustments during production runs, enabling manufacturers to remain competitive in a fast-paced market.

Moreover, the integration of smart technologies, such as Internet of Things (IoT) capabilities in roll forming machines, enables real-time monitoring and predictive maintenance. This not only increases productivity but also reduces downtime and operational costs.

Conclusion

Knudson Roll Forming exemplifies how traditional manufacturing techniques can evolve to meet contemporary demands. The process not only ensures high efficiency and precision but also adapts to various industries, driving innovation through constant improvements. As technologies continue to develop, the prospects for roll forming appear promising, paving the way for even more sophisticated applications and enhanced production methodologies. Whether in construction, automotive, or consumer goods, Knudson Roll Forming remains a cornerstone of modern manufacturing excellence.