The rapid pace of industrial development demands advanced solutions for construction and infrastructure projects. The introduction of [C/Z purlin automatic lines] represents a leap forward in manufacturing efficiency and product consistency within the construction industry, offering indispensable support for creating strong and reliable building frameworks. This innovative machinery redefines the landscape of metal fabrication by providing seamless operations that combine precision with speed.

C/Z purlin automatic lines are designed to manufacture C and Z-shaped purlins, essential components in the construction of metal buildings. These machines are a testament to engineering excellence, embodying a synergy of cutting-edge technology and robust design principles. Professionals in the field recognize the utility of C/Z purlin automatic lines in delivering high-quality outputs that meet the stringent requirements of the modern construction environment.

Experience is a critical factor in appreciating the full potential of C/Z purlin automatic lines. Manufacturers with deep industry experience understand that these machines significantly reduce lead times and operational costs. The automatic line setup ensures continuous production with minimal manual intervention, enhancing the overall efficiency while reducing the likelihood of human error. This capability is crucial for projects with tight deadlines and high precision demands, where even minor delays could escalate costs.

The expertise required to operate C/Z purlin automatic lines is steeped in a robust understanding of mechanical engineering and operational protocols. Operators are typically trained professionals who specialize in interpreting technical schematics and maintaining the equipment's optimal performance. Continuous investment in training ensures that the workforce remains capable of leveraging the full potential of these sophisticated machines, thus guaranteeing the highest production standards.

When it comes to authoritativeness, the manufacturers of C/Z purlin automatic lines are often industry pioneers who contribute to setting global standards. Through extensive research and development, these leaders introduce innovations that expand the functional capabilities of purlin forming systems. Many leading brands have established their reputation by consistently delivering machines that exceed expectations in terms of durability, precision, and adaptability to various material specifications.

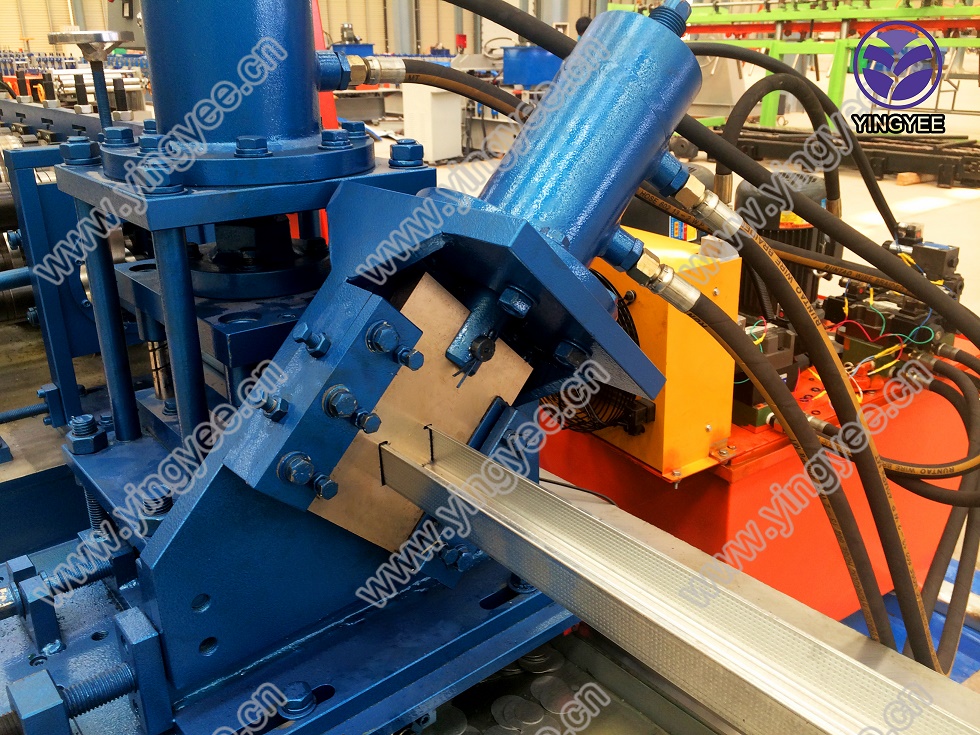

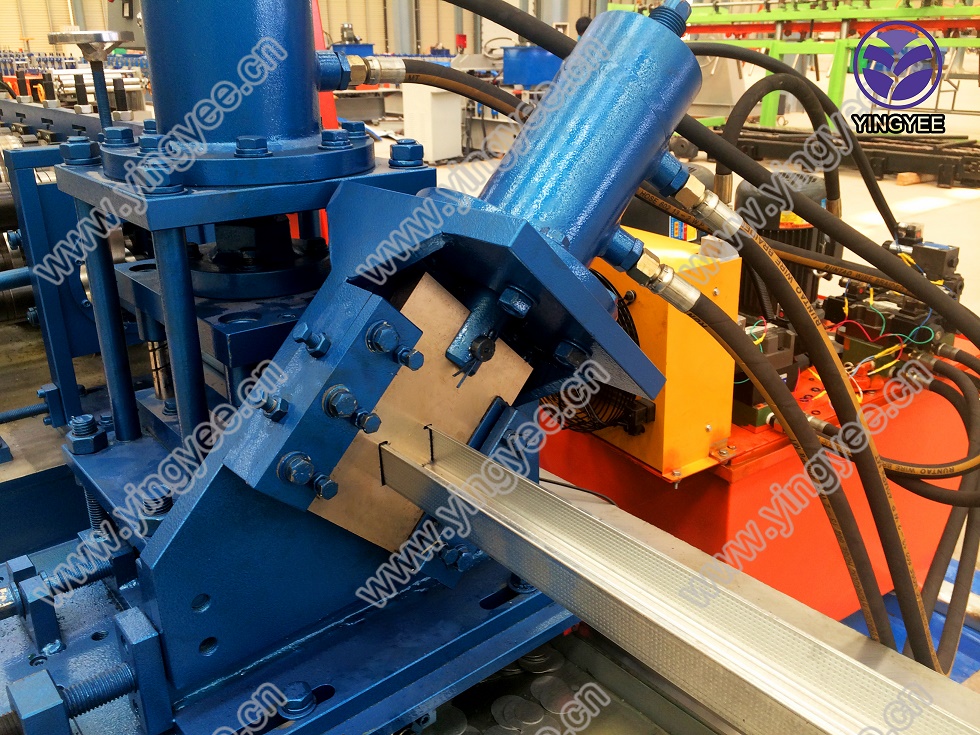

c/z purlin automatic line

Trustworthiness in C/Z purlin automatic lines is built on a foundation of consistent performance and reliable service life. Potential buyers can evaluate this through detailed performance metrics and user testimonials, often available through dedicated reviews from recognized industry bodies. The reliability of these machines is further bolstered by comprehensive warranties and responsive customer service channels that demonstrate a manufacturer's commitment to supporting their clients long after the point of sale.

From an SEO perspective, it's paramount to highlight the unique value propositions that C/Z purlin automatic lines offer. This includes focusing on the advancements in automation and the resultant improvements in production quality and speed. Effective digital content should emphasize case studies and user reviews that underline real-world applications and success stories, thus reinforcing the trust and authority aspects through verifiable experiences.

Search engine optimization for such a niche product involves crafting content that resonates with industry professionals, such as engineers and project managers, who are looking for credible sources of information. Utilizing a strategic combination of targeted keywords, such as high-efficiency purlin production, automated purlin forming technology, and advanced metal fabrication machinery, ensures that content connects with the intended audience while boosting search engine rankings.

In conclusion, C/Z purlin automatic lines epitomize the convergence of technology and industrial needs, serving as pivotal tools in the construction sector. Their ability to produce high-quality purlins with efficiency and precision makes them invaluable assets. By integrating thorough expertise with trusted manufacturing practices, these machines not only advance manufacturing processes but also fortify the structural integrity of contemporary architecture. As industries continue to evolve, the role of such advanced machinery becomes ever more critical, reinforcing their place as fundamental components in the assembly of the modern world.