The Concept of a Standing Seam Making Machine

In the realm of modern construction and roofing solutions, the standing seam roof system has gained immense popularity due to its durability, aesthetic appeal, and energy efficiency. At the heart of this innovative roofing technique lies a remarkable device known as the standing seam making machine. This machine plays a pivotal role in the production of standing seam metal panels, which are essential for both residential and commercial buildings.

Understanding Standing Seam Roofing

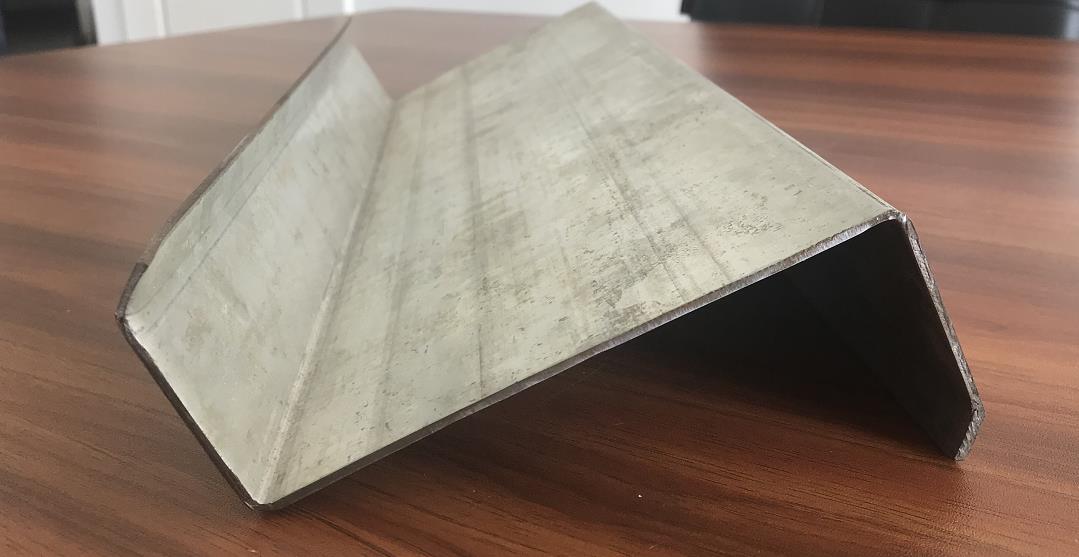

Standing seam roofs feature vertical panels with interlocking seams that rise above the plane of the roof. This design allows for natural expansion and contraction due to temperature changes, which is particularly important in climates with significant temperature fluctuations. The concealed fasteners used in standing seam roofs offer superior protection against the elements, preventing leaks and prolonging the lifespan of the roofing system.

The Role of a Standing Seam Making Machine

The standing seam making machine is an advanced piece of equipment specifically designed for the fabrication of metal panels used in standing seam roofing systems. It typically combines several processes such as shearing, rolling, and forming, making it crucial for manufacturers aiming to produce high-quality roofing materials efficiently.

1. Shearing The first step involves cutting metal sheets to the desired length. This is critical because precision in size ensures that the panels fit together perfectly during installation.

2. Rolling Next, the machine rolls the flat metal sheets into the desired profile. This can involve creating various rib heights or widths that accommodate different aesthetic and structural requirements. The rolling process is vital as it determines the overall look and performance of the final product.

3. Forming Many machines also include a forming stage, where the edges of the metal panels are shaped to create the standing seam. This ensures that the panels can interlock securely, enhancing their structural integrity and weather resistance.

4. Customization Today’s standing seam making machines often come with programmable software that allows manufacturers to customize panel dimensions and profiles easily. This level of flexibility is essential for responding to specific client needs and adapting designs to various architectural styles.

Advantages of Using a Standing Seam Making Machine

The benefits of employing a standing seam making machine in metal panel production are significant

- Efficiency and Speed Automated machines can produce large volumes of panels in a fraction of the time it would take through manual processes, thus enhancing overall productivity.

- Consistency These machines deliver uniformity in panel production, which is crucial in ensuring that all panels fit together accurately, reducing the risk of errors during installation.

- Cost-Effectiveness By streamlining the production process, manufacturers can save on labor and material costs, ultimately delivering more competitive pricing to their customers.

- Durability of Product Utilizing high-quality materials and precise manufacturing techniques ensures that the final product meets the rigorous standards required for roofing applications, thus enhancing longevity and performance.

Conclusion

In conclusion, the standing seam making machine is an invaluable tool in the growing industry of metal roofing. Its ability to produce durable, aesthetically pleasing, and energy-efficient panels is unmatched. As construction practices evolve and the demand for high-quality roofing materials increases, investments in advanced machines like the standing seam making machine will continue to be a strategic choice for manufacturers. By embracing this technology, the construction industry can not only meet but exceed the expectations of modern architecture, ensuring that buildings are both functional and visually appealing.