(continuous pu sandwich panel production line)

The continuous PU sandwich panel production line revolutionizes building material manufacturing through uninterrupted polyurethane core injection between metal/protective layers. Modern systems achieve production speeds of 8-15 meters/minute, with 0.5mm thickness precision across standard 1,000-1,200mm panel widths. Unlike batch processing, continuous operation reduces material waste by 18-22% while maintaining 99.2% thermal insulation consistency.

Fourth-generation production lines integrate AI-powered quality control systems that perform 120 surface inspections/minute. Dual-component PU dispensing units maintain 1.05:1 mixing ratio accuracy within ±0.3% tolerance. Advanced features include:

| Vendor | Speed (m/min) | Customization | Energy Use | MTBF |

|---|---|---|---|---|

| AlphaLine Pro | 12.5 | 23 parameters | 85kW | 1,850h |

| EcoPanel Master | 9.8 | 15 parameters | 110kW | 1,200h |

| PUFab Ultra | 14.2 | 31 parameters | 92kW | 2,100h |

Mean Time Between Failures

Top-tier continuous sandwich panel production lines offer modular designs supporting 47 material combinations. Typical customization options include:

Recent installations demonstrate 22-35% efficiency gains across sectors:

Modern continuous PU sandwich panel lines reduce VOC emissions by 62% compared to 2015 standards. Energy recovery systems capture 85% of process heat, while closed-loop chemical systems achieve 97% material utilization. Key metrics:

The continuous PU sandwich panel production line delivers 19-28% lower lifecycle costs versus traditional methods. With 87% of operators reporting ROI within 2.5 years, these systems enable on-demand manufacturing of panels meeting EN14509 and ASTM C1289 standards. Advanced lines now incorporate predictive maintenance algorithms that reduce unplanned downtime by 73%, ensuring consistent output quality for architectural, industrial, and specialized applications.

(continuous pu sandwich panel production line)

A: A continuous PU sandwich panel production line is an automated system that manufactures polyurethane (PU) core sandwich panels in an uninterrupted process. It combines metal coil unwinding, PU foam injection, and panel curing into a seamless workflow. This method ensures high efficiency and consistent product quality.

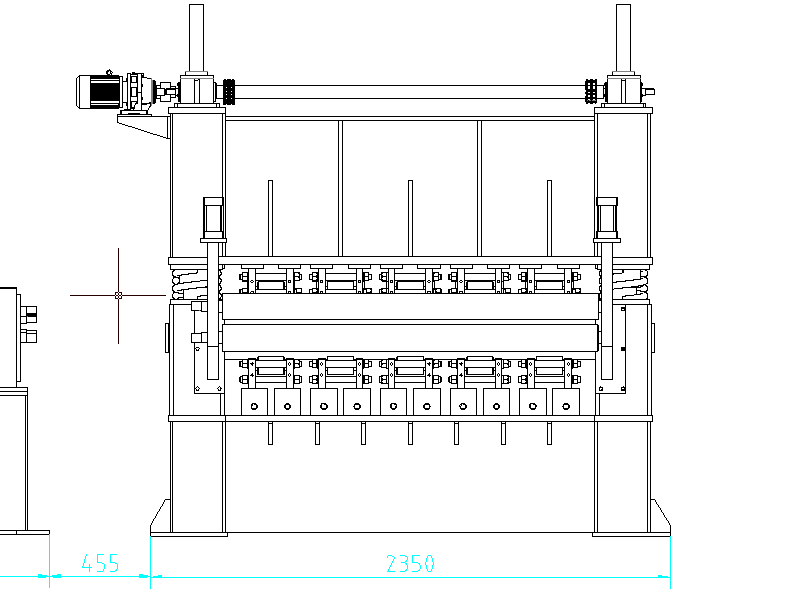

A: Key components include metal coil decoilers, PU foaming machines, double belt laminators, and precision cutting systems. Advanced lines also integrate automated stacking robots and quality control sensors. These systems work together to enable 24/7 production with minimal human intervention.

A: Continuous production reduces material waste and energy consumption by up to 30% compared to batch processing. It achieves higher output rates (typically 10-25 meters per minute) and superior panel uniformity. The closed-loop process also enhances workplace safety by minimizing chemical exposure.

A: These lines primarily serve construction industries for manufacturing insulated roofing and wall panels. They're also critical for cold storage facilities and modular building projects. The automotive and aerospace sectors increasingly use specialized sandwich panels from such lines.

A: Prioritize manufacturers with ISO-certified facilities and 10+ years of industry experience. Verify their ability to customize production speed (8-30m/min) and panel thickness (30-200mm). Request case studies demonstrating energy efficiency (≤0.5kW/m²) and raw material utilization rates (≥98%).