Understanding Andes Coil Processing Innovations and Applications

Andes coil processing, a cutting-edge technique in the manufacturing industry, has garnered significant attention for its efficiency and versatility. This method primarily involves the processing of coils made from various materials, including metals and polymers, to create finished products that meet specific industrial standards. With advancements in technology, Andes coil processing has evolved, enabling manufacturers to optimize operations, reduce waste, and enhance product quality.

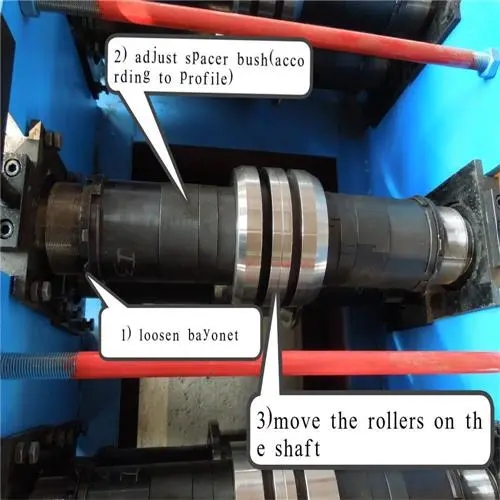

At its core, Andes coil processing utilizes sophisticated machinery to handle coils in an automated manner. This includes unwinding, shaping, and re-coiling materials with remarkable precision. The process starts with the selection of raw coil materials, which can vary in thickness, material composition, and surface finish. Once the appropriate coils are chosen, they undergo a series of automated steps that include feeding, cutting, bending, and sometimes even coating.

Understanding Andes Coil Processing Innovations and Applications

Moreover, Andes coil processing promotes sustainability. With increasing global emphasis on environmentally friendly practices, this method stands out by minimizing waste and maximizing material utilization. The ability to design processes that optimize material cuts means that manufacturers can produce more from less. Additionally, the robust data analytics that accompany these advanced systems allow companies to monitor and adjust operations in real-time, further reducing energy consumption and waste generation.

The application of Andes coil processing spans various industries, including automotive, aerospace, electronics, and construction. In the automotive sector, for instance, manufacturers rely on this technique to produce components such as chassis and body parts, where precision and material integrity are paramount. Similarly, in aerospace, critical components must meet strict regulatory standards, making the reliable nature of Andes coil processing invaluable.

Furthermore, the electronics industry has also benefited significantly from this innovative processing technique. With the ongoing miniaturization of devices, manufacturers must utilize precise and flexible manufacturing methods to produce intricate components that fit within compact designs. Andes coil processing allows for such versatility, enabling the production of finely detailed circuits and other components essential for modern electronic devices.

Looking ahead, the future of Andes coil processing appears promising, with ongoing research and development aimed at enhancing its capabilities further. Innovations such as artificial intelligence and machine learning are being integrated into processing systems to predict failures, optimize maintenance schedules, and even personalize production based on client specifications. As the demand for customization grows, these intelligent systems will allow manufacturers to remain competitive by adapting quickly to market needs while maintaining high quality.

In conclusion, Andes coil processing represents a significant innovation in the realm of manufacturing, offering efficiency, sustainability, and versatility. Its applications across numerous industries underscore its importance in contemporary production processes. As technology continues to advance, the implementation of sophisticated systems in Andes coil processing is expected to expand, leading to even greater improvements in productivity and product quality, thereby shaping the future of manufacturing. Manufacturers that embrace this transformative approach are likely to lead the way in their respective fields, driving innovation and meeting the ever-evolving demands of the global market.