The Benefits and Applications of Roof Cold Roll Forming Machines

Roof cold roll forming machines have revolutionized the construction and roofing industries by providing efficient, precise, and cost-effective solutions for manufacturing roofing materials. These machines are designed to create a variety of profiles used in metal roofing systems, and their benefits have led to a rise in their adoption across diverse sectors.

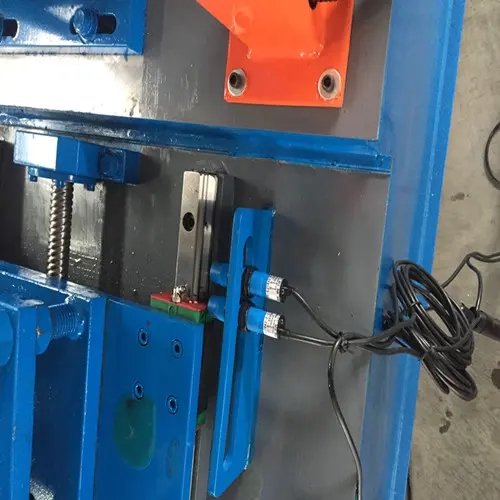

One of the primary advantages of using cold roll forming machines is their efficiency. These machines operate by continuously feeding flat metal sheets, often galvanized or coated, through rollers that shape them into predetermined profiles. This process allows for high-speed production, significantly reducing manufacturing time and labor costs. Compared to traditional methods, cold roll forming enables producers to scale up production without compromising on quality.

Precision is another critical benefit of roof cold roll forming machines

. The advanced technology used in these machines ensures that every piece produced has uniform dimensions and smooth finishes, which is crucial for the seamless installation of roofing systems. The ability to maintain tight tolerances minimizes waste and enhances the overall performance of the roofing materials, particularly in terms of weather resistance and durability.

Moreover, cold roll forming machines are highly versatile. They can produce a wide range of profiles, including standing seam, corrugated sheets, and regular tile shapes, catering to various architectural styles and construction requirements. This adaptability makes them ideal for different projects, from residential buildings to large commercial complexes and industrial structures.

The environmental aspect of using cold roll forming technology also deserves attention. Metal materials can be recycled, and the efficiency of the forming process reduces energy consumption, leading to less environmental impact compared to traditional roofing material manufacturing methods. Additionally, the durability of metal roofing contributes to sustainability, as these roofs often last much longer than their non-metal counterparts.

In conclusion, roof cold roll forming machines are essential tools in the modern construction landscape. Their efficiency, precision, versatility, and environmental benefits make them highly favorable for manufacturers and builders alike. As the demand for high-quality and sustainable roofing solutions continues to grow, the role of cold roll forming technology is expected to expand, further enhancing the capabilities of the roofing industry.