The Purlin Stud Machine A Revolutionary Tool in Metal Fabrication

In the realm of construction and metal fabrication, efficiency and precision are paramount. Among the various tools and machines that facilitate these processes, the purlin stud machine stands out as a revolutionary piece of equipment that meets the rigors of modern building requirements. This machine specializes in the production of metal purlins and studs, which are essential components for various structural applications, including residential, commercial, and industrial buildings.

Understanding Purlins and Studs

Purlins serve as horizontal supports for roofs, while studs are vertical framing members used in walls. Both components are typically made from steel or other metal materials due to their strength and durability. The increased use of steel in modern construction can be attributed to its ability to bear heavy loads, resist environmental factors, and contribute to energy efficiency when properly insulated. Conventional methods of producing purlins and studs often involve labor-intensive manual processes, leading to inefficiencies and inconsistencies. The advent of the purlin stud machine has transformed these traditional practices into streamlined operations.

Features of the Purlin Stud Machine

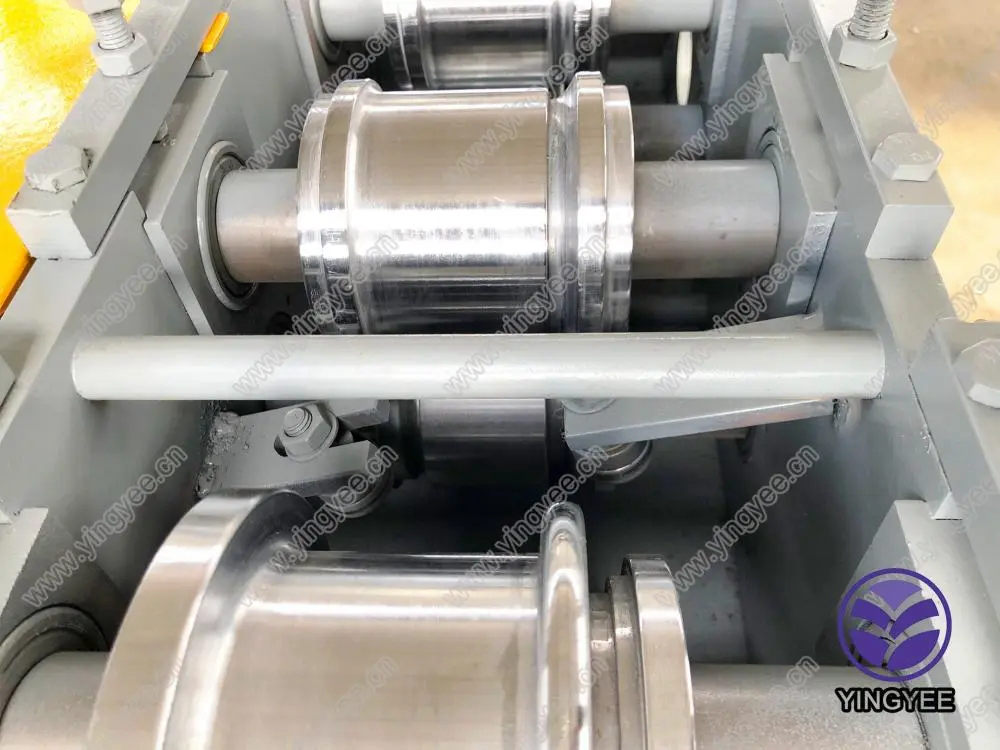

A purlin stud machine is designed to automate the manufacturing process, thereby reducing human labor and mitigating the risks of error

. These machines integrate advanced technology, such as Computer Numerical Control (CNC), allowing them to produce high-quality purlins and studs with precise measurements and specifications. The machine operates through a series of processes that include cutting, punching, and forming metal sheets into the desired shapes.

One of the most significant advantages of the purlin stud machine is its capability to handle varying sizes and profiles. This versatility enables fabricators to produce a range of products tailored to specific construction needs. Furthermore, many modern purlin stud machines come equipped with software that simplifies the design and production process. This software allows operators to input specifications and generate complex designs that would be difficult to achieve manually.

Benefits of Using a Purlin Stud Machine

The introduction of the purlin stud machine not only improves production speed but also enhances overall quality. With automated systems, the consistency of the products is significantly increased, resulting in fewer defects and wastage. This efficiency translates to cost savings for businesses in terms of both materials and labor.

Moreover, the use of a purlin stud machine contributes to sustainability in construction. By optimizing the use of materials and minimizing waste, these machines support eco-friendly practices. This is increasingly important as the construction industry seeks to align with global sustainability goals.

Conclusion

In conclusion, the purlin stud machine represents a significant advancement in the field of metal fabrication. Its ability to automate the production of critical structural components with high precision and efficiency makes it a valuable tool for the modern builder. As construction demands continue to evolve, tools like the purlin stud machine will play an essential role in meeting the challenges of the industry while promoting sustainability and effectiveness. Embracing such innovative machinery is crucial for businesses striving to stay competitive in the ever-changing market landscape.