Exploring Light Keel Roll Forming Machine Suppliers

In the ever-expanding world of industrial manufacturing, roll forming technology has emerged as a critical process in the production of various metal components. Among the plethora of roll forming machines, light keel roll forming machines play a significant role, particularly in industries focusing on the construction of lightweight structures. This article dives into the essential aspects of light keel roll forming machines and the suppliers who provide these innovative solutions to the market.

Understanding Light Keel Roll Forming Machines

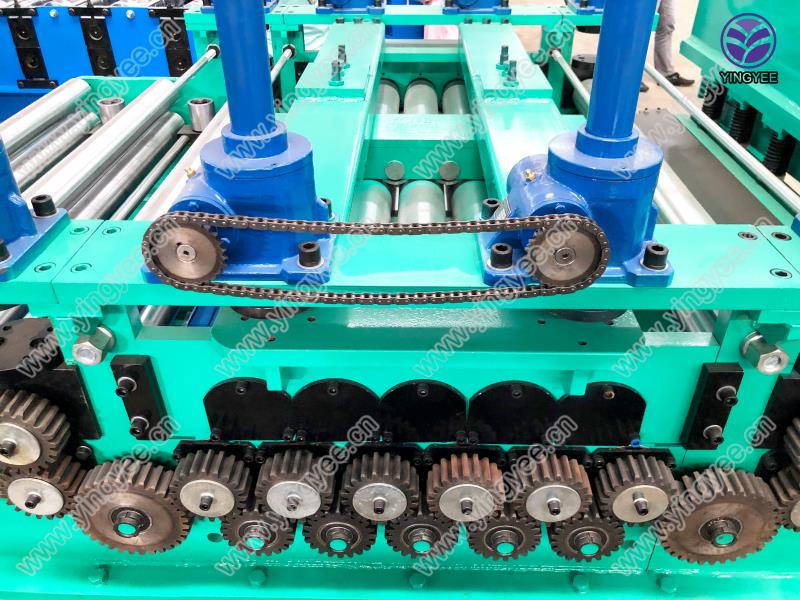

Light keel roll forming machines are specialized equipment designed to produce metal profiles, often used in the construction of frames for drywall, partitions, and ceilings. These machines operate by continuously bending a strip of metal, typically steel or aluminum, into desired shapes through a series of rolls. The resulting profiles—known as keels—are integral components in the construction of lightweight structures, offering strength while minimizing overall weight.

The versatility of light keel roll forming machines allows them to create various profiles, including U, C, and L shapes. These profiles are not only crucial in the construction industry, but they also find applications in manufacturing furniture, automotive parts, and other lightweight assemblies. Thus, selecting the right roll forming machine supplier is essential for businesses looking to optimize their production processes and maintain high-quality standards.

Factors to Consider When Choosing a Supplier

1. Quality and Reliability The reliability of the machinery is paramount. Suppliers should provide machines constructed from high-quality materials with precise engineering. Clients should inquire about the longevity and maintenance needs of the machines offered.

2. Customization Options Every business has unique requirements based on their production goals. An ideal supplier should offer customizable solutions tailored to your specific needs, whether for unique profiles or production volume.

3. Technical Support and Training The complexity of operating a light keel roll forming machine requires adequate training for staff. Suppliers that provide comprehensive technical support and training resources are invaluable to ensure smooth operations and minimize downtime.

4. Reputation and Experience Selecting an experienced supplier with a solid reputation in the industry can significantly impact the quality of equipment sourced. Researching customer reviews and testimonials can provide insight into potential suppliers' credibility.

5. After-sales Service A reliable after-sales service is crucial for maintaining machine performance. Suppliers should offer warranties, spare parts availability, and quick response times for service requests.

Leading Suppliers in the Market

There are several prominent suppliers globally known for their high-quality light keel roll forming machines. Some of these include

1. Forming Technologies Inc. (FTI) With decades of experience, FTI is a leader in providing custom roll forming solutions tailored to various industries. Their emphasis on quality and precision makes them a trusted name among manufacturers.

2. Gongyi City Jin Wood Machinery Co., Ltd. This supplier is renowned for its advanced technology and efficient production lines. They offer a range of forming machines, including those specifically designed for lightweight keels.

3. Zhongtuo Roll Forming Machinery Known for innovative design and robust performance, Zhongtuo provides competitive machinery that meets international standards. They focus on continuous improvement and technological advancements.

4. Ruitai Machinery Specializing in roll forming machinery, Ruitai has established a solid reputation for quality and customer service. Their machines are equipped with the latest technology, ensuring high productivity and reliability.

Conclusion

In conclusion, light keel roll forming machines are pivotal in modern manufacturing, offering unparalleled efficiency and versatility in producing lightweight steel structures. Selecting the right supplier can significantly affect a company's operational success. By considering quality, customization, support, and reputation, manufacturers can find a partner that meets their needs. With trusted suppliers leading the market, businesses can confidently invest in light keel roll forming technology, paving the way for innovation and growth in their respective industries.