The Marvel of IBR Making Machines Revolutionizing Construction

In the ever-evolving world of construction, efficiency and innovation are key to meeting the increasing demands of infrastructure development. Among the groundbreaking technologies that have emerged, the IBR (Inverted Bending Rib) making machine stands out as a marvel that revolutionizes the way roofing sheets are manufactured. This article delves into the functionalities, advantages, and broader implications of IBR making machines in the construction industry.

Understanding IBR Roofing

Before exploring the intricacies of IBR making machines, it is essential to comprehend what IBR roofing entails. IBR sheets are corrugated metal sheets widely used in the construction of roofs and walls. These sheets are popular for their strength, durability, and aesthetic appeal. The unique inverted rib design enhances the sheet's structural integrity and allows for effective water runoff, making it ideal for regions with heavy rainfall.

The Functionality of IBR Making Machines

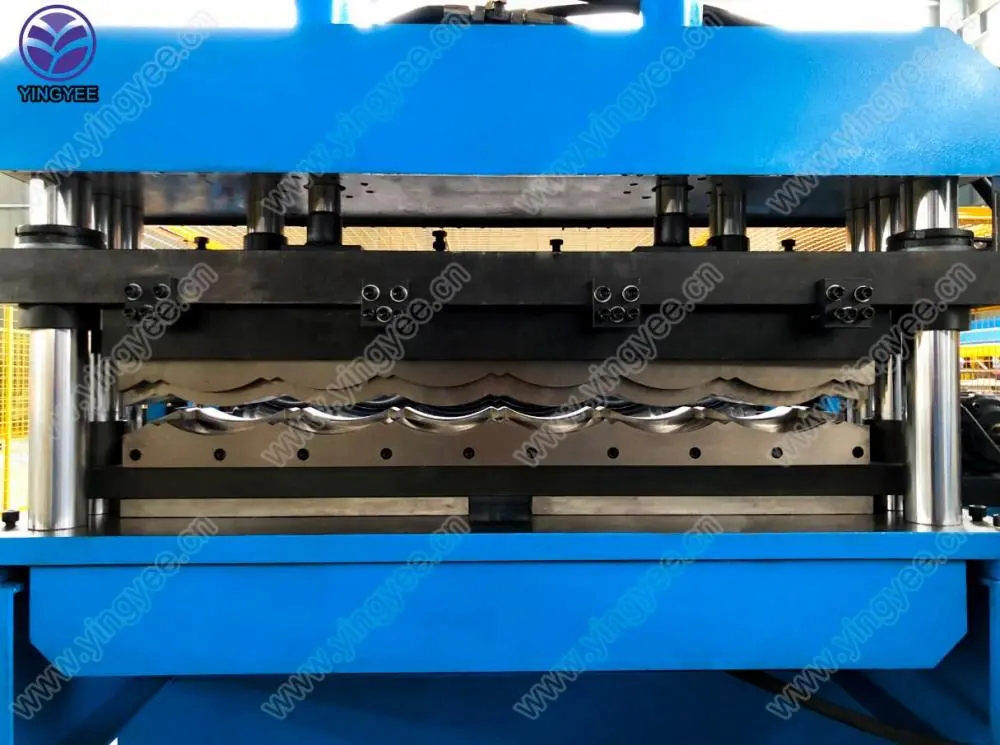

IBR making machines are sophisticated pieces of equipment designed to produce these corrugated sheets efficiently. The process begins with raw materials, typically galvanized steel or aluminum coils. The coils are fed into the machine, which then shapes the metal into the desired profile using a series of rollers.

The machine operates through a continuous process, ensuring minimal waste and high precision in dimensions. Advanced IBR making machines are equipped with computerized controls that automate the process, allowing for fine-tuning of thickness, width, and length. Additionally, some models come with features that enable on-the-fly adjustments, providing manufacturers with the flexibility to meet diverse construction needs.

Advantages of Using IBR Making Machines

1. Cost-Effectiveness One of the most significant advantages of IBR making machines is their ability to produce high-quality roofing sheets at a lower cost. By minimizing waste material and reducing labor costs, manufacturers can offer competitive prices, making IBR roofing accessible to a broader market.

2. Speed and Efficiency With the automated processes involved, IBR making machines can produce large volumes of sheets in a short amount of time. This rapid production rate supports the fast-paced nature of construction projects, where time is often a critical factor.

3. High Customization The versatility of IBR making machines allows manufacturers to customize sheets according to specific project requirements. Whether it’s altering the dimensions, thickness, or color, these machines can accommodate varying specifications without significant downtime.

4. Sustainability Environmentally conscious practices are increasingly important in the construction industry. IBR making machines contribute to sustainability efforts by optimizing material use and enabling the production of recyclable sheets. Additionally, they can be powered by renewable energy sources, further reducing the carbon footprint.

The Broader Implications

The impact of IBR making machines extends beyond cost savings and efficiency. They play a crucial role in enhancing the overall quality of construction materials. With consistently manufactured sheets, builders can ensure that structural integrity meets safety standards, which is paramount in any construction project.

Moreover, as green building practices gain traction, the role of IBR machines in producing sustainable and eco-friendly materials will become even more significant. Developers and contractors are increasingly prioritizing materials that contribute to energy efficiency and reduced environmental impact.

Conclusion

The emergence of IBR making machines represents a significant leap forward in the construction industry. By streamlining the production of high-quality roofing sheets, these machines not only boost efficiency and cost-effectiveness but also promote sustainability and customization. As the demand for innovative construction solutions continues to grow, the role of IBR making machines will likely expand, fostering advancements that shape the future of building. In an industry where quality and speed are crucial, embracing such technology is no longer just an option; it is a necessity for those wishing to stay ahead in the competitive landscape of construction.