The Downspout Elbow Machine A Key Component in Rainwater Management Systems

In modern construction and architecture, effective water management is critical to preventing property damage and ensuring environmental sustainability. One essential component in any rainwater collection system is the downspout elbow, a fitting that directs rainwater from the vertical downspouts away from the building’s foundation. The downspout elbow machine plays a vital role in manufacturing these fittings, ensuring they are produced with precision and efficiency.

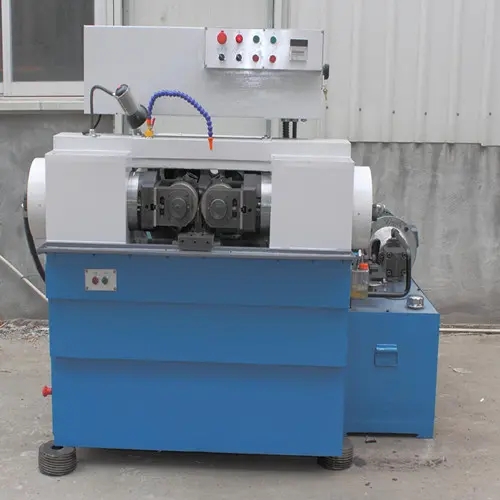

The downspout elbow machine is specifically designed to produce elbows that connect downspouts to gutters, allowing for a smooth transition of water flow. These machines are equipped with advanced technology that enables the production of various sizes and angles of elbows, catering to different architectural needs and regional climate conditions. By automating the manufacturing process, these machines significantly reduce labor costs and minimize production time, making them an invaluable asset for manufacturers.

One of the notable features of the downspout elbow machine is its ability to handle a variety of materials, including aluminum, vinyl, and galvanized steel

. This versatility is crucial since different regions may prefer specific materials based on local weather conditions and aesthetic considerations. The machine's adaptability allows manufacturers to respond swiftly to market demands, producing elbows that are durable and capable of withstanding harsh weather elements.

The efficiency of the downspout elbow machine also contributes to sustainability efforts. By producing high-quality elbows with minimal waste, manufacturers can ensure that less material is discarded during the production process. This is particularly important in today’s eco-conscious market, where consumers increasingly seek products that support environmental sustainability. Additionally, the use of durable materials in manufacturing downspout elbows means that these fittings will last longer, reducing the need for replacements and further conserving resources.

Another advantage of using a downspout elbow machine is the precision it offers. Automated processes ensure that the elbows produced fit snugly and securely, minimizing the risk of leaks. Properly functioning downspouts and elbows are crucial for directing water away from a building's foundation, thereby preventing erosion, basement flooding, and costly damage to the property.

Furthermore, the adoption of computer numerical control (CNC) technology in downspout elbow machines has revolutionized the production process. CNC machines allow for exact measurements and customized designs, enabling manufacturers to create elbows tailored to specific project requirements. This level of customization enhances the overall effectiveness of rainwater management systems, providing solutions that are as unique as the buildings they serve.

In conclusion, the downspout elbow machine is a pivotal tool in the manufacturing of essential components for rainwater management systems. Its efficiency, material versatility, and precision production capabilities not only optimize manufacturing processes but also contribute to the sustainability and effectiveness of water management practices. As construction continues to face challenges related to climate change and urbanization, the importance of innovative solutions, such as the downspout elbow machine, will only become more pronounced. Investing in such technology is a step toward smarter and more resilient infrastructure that can adapt to the demands of the future.