Understanding the CZU Steel Purlin Frame Roll Forming Machine

In the modern construction and manufacturing industries, the demand for robust, efficient, and cost-effective structural components is ever-increasing. Among the various technologies that have emerged to meet these demands is the roll forming machine, specifically the CZU steel purlin frame roll forming machine. This innovative equipment plays a pivotal role in the production of steel purlins, which are essential components in building frameworks.

What Is a Steel Purlin?

Steel purlins are horizontal support beams utilized in the construction of roofs and walls. They act as a vital structural element, providing stability and support for other components. Purlins can be made from various materials, but steel is favored due to its strength, durability, and resistance to various environmental factors. The CZU steel purlin frame roll forming machine specializes in producing these purlins efficiently and consistently.

How Does the CZU Steel Purlin Frame Roll Forming Machine Work?

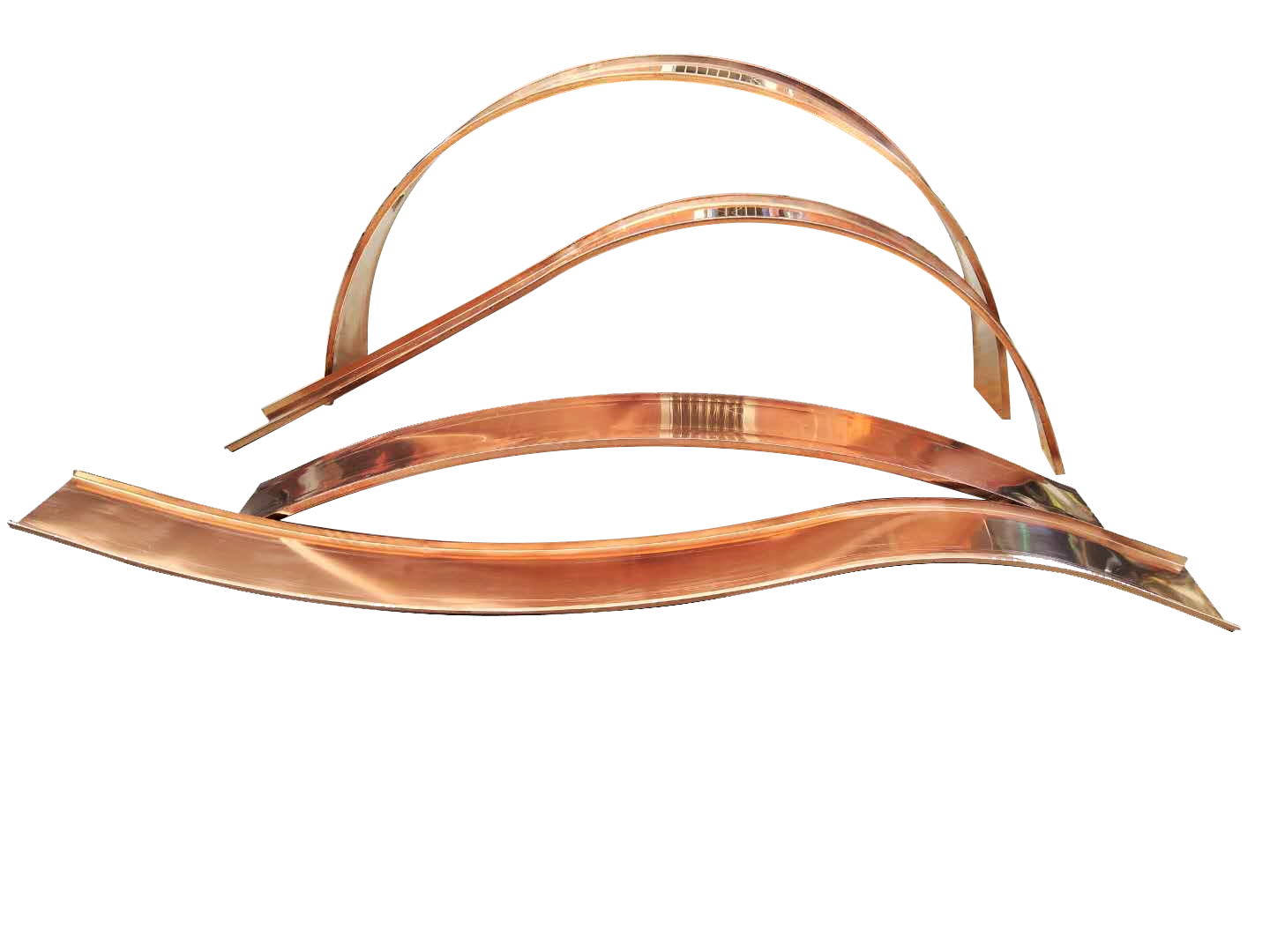

The CZU roll forming machine operates on a continuous process that involves feeding a flat strip of steel into the machine. As the strip passes through various rollers, it undergoes a series of shaping processes where it is progressively formed into the desired purlin profile. The machine can produce various sizes and shapes of purlins, including C, Z, and U profiles, depending on the project requirements.

The roll forming process is highly efficient, allowing for the production of large quantities of purlins without significant waste. The machine is designed to maintain precise measurements and cut lengths, ensuring that each purlin meets the necessary specifications for structural integrity.

Advantages of Using the CZU Steel Purlin Frame Roll Forming Machine

1. Efficiency The continuous roll forming process minimizes downtime and allows for high production rates. This efficiency translates into reduced labor costs and quicker project completion times.

2. Precision The CZU machine is engineered for precision, enabling it to produce purlins with tight tolerances. This accuracy is crucial in construction, where even minor deviations can lead to structural concerns.

3. Versatility This machine can produce a variety of profiles to meet diverse project requirements. Whether a contractor needs standard C or Z purlins or custom shapes, the CZU machine can adapt to the task.

4. Cost-Effectiveness By streamlining the manufacturing process and minimizing waste, the CZU roll forming machine can significantly reduce material costs. Additionally, the durability of steel purlins reduces maintenance costs over the lifespan of the structure.

5. Automation Modern CZU machines often come equipped with advanced automation technologies, including computer numerical control (CNC). This automation enhances production efficiency and accuracy while reducing labor reliance.

Applications of Steel Purlins

Steel purlins produced by the CZU roll forming machine have a wide range of applications in construction. They are commonly used in

- Industrial Buildings Steel purlins provide the backbone for warehouses, factories, and manufacturing facilities, where strong and reliable structures are essential.

- Commercial Properties Retail spaces and office buildings utilize steel purlins for their strength and adaptability in various design configurations.

- Agricultural Structures Purlins are extensively used in the construction of barns, storage facilities, and other agricultural buildings due to their resistance to environmental stressors.

- Residential Construction Increasingly, steel purlins are being incorporated into residential designs for roof support and framing due to their lightweight nature and ease of installation.

Conclusion

The CZU steel purlin frame roll forming machine represents a significant advancement in the manufacturing of structural components. Its efficiency, precision, and versatility make it an invaluable tool for the construction industry, meeting the growing demand for high-performance building materials. As technology continues to evolve, machines like the CZU will likely play an even greater role in shaping the future of construction, ensuring that it meets the structural, aesthetic, and sustainability needs of modern architecture. With the right equipment at their disposal, manufacturers can not only fulfill current market demands but also pioneer innovative building solutions for tomorrow.