In the dynamic landscape of construction and manufacturing, the customized angle stud and track, drywall C channel, main channel, and wall angle roll forming machines play a pivotal role in modern structural innovations. These machines, designed to meet specific industry demands, offer a seamless merging of precision engineering and customizable flexibility, providing a distinct advantage in a competitive market.

The evolution in roll forming technology allows for the production of high-quality metal profiles that meet stringent industry standards. Customized angle stud and track roll forming machines, for instance, are engineered to produce precise and consistent metal shapes required in framing applications. This customization is not merely about dimensional accuracy but extends to include materials used and the specific bending and cutting techniques required to achieve unique architectural designs. Industry experts recognize that these machines bring a level of expertise and detailed craftsmanship to the production process, revolutionizing how components are manufactured for various construction needs.

Roll forming machines for drywall applications leverage cutting-edge technology to create C channels, main channels, and wall angles. These components are crucial in providing structural strength and stability in building projects. The expertise embedded within these machines is evident in their ability to produce a wide range of profiles that meet specific criteria of endurance, weight, flexibility, and compatibility with other construction elements. By producing lightweight yet durable components, these machines contribute significantly to minimizing material wastage and optimizing production efficiency—an experience that speaks to their credible role in sustainable building practices.

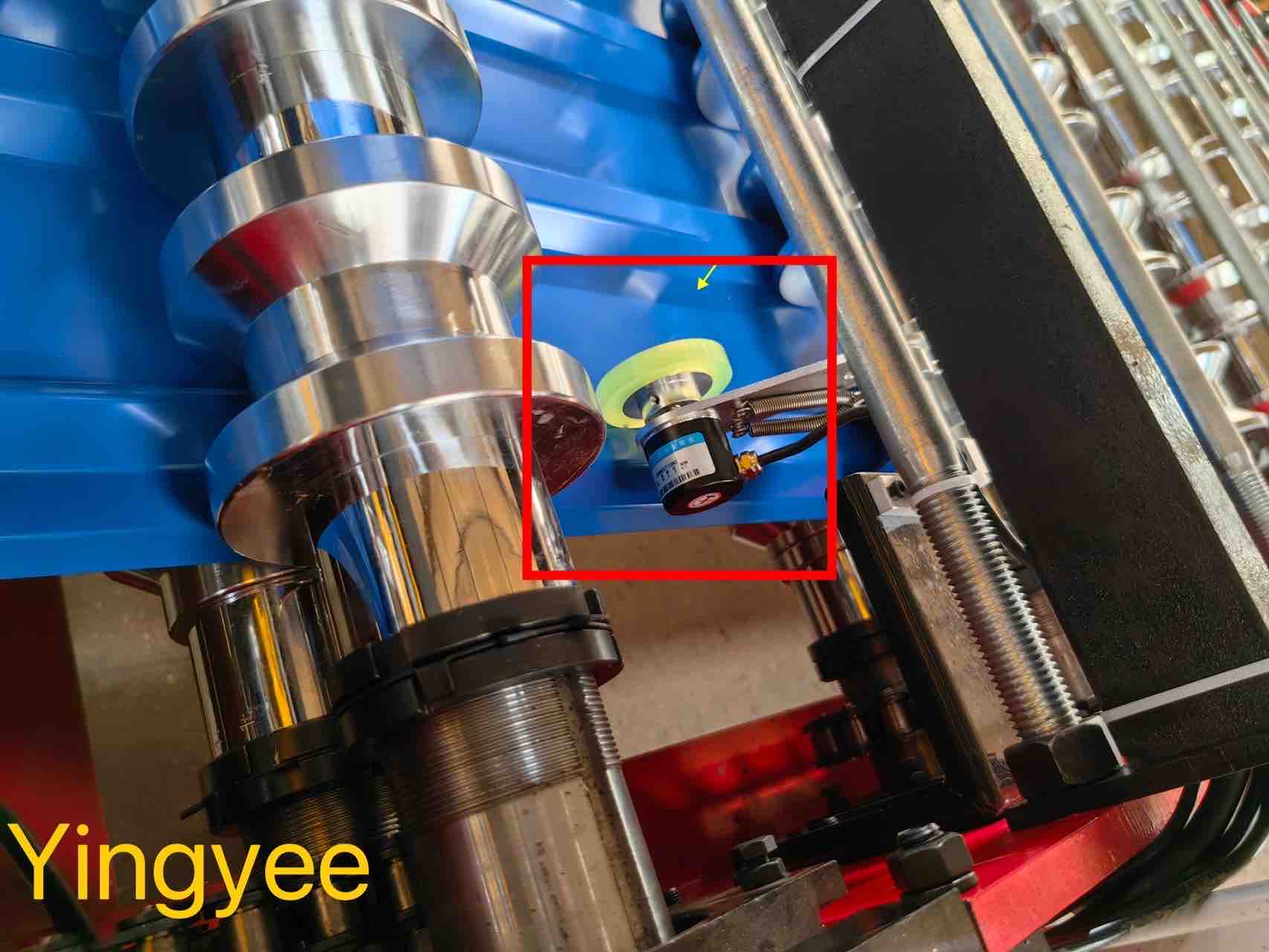

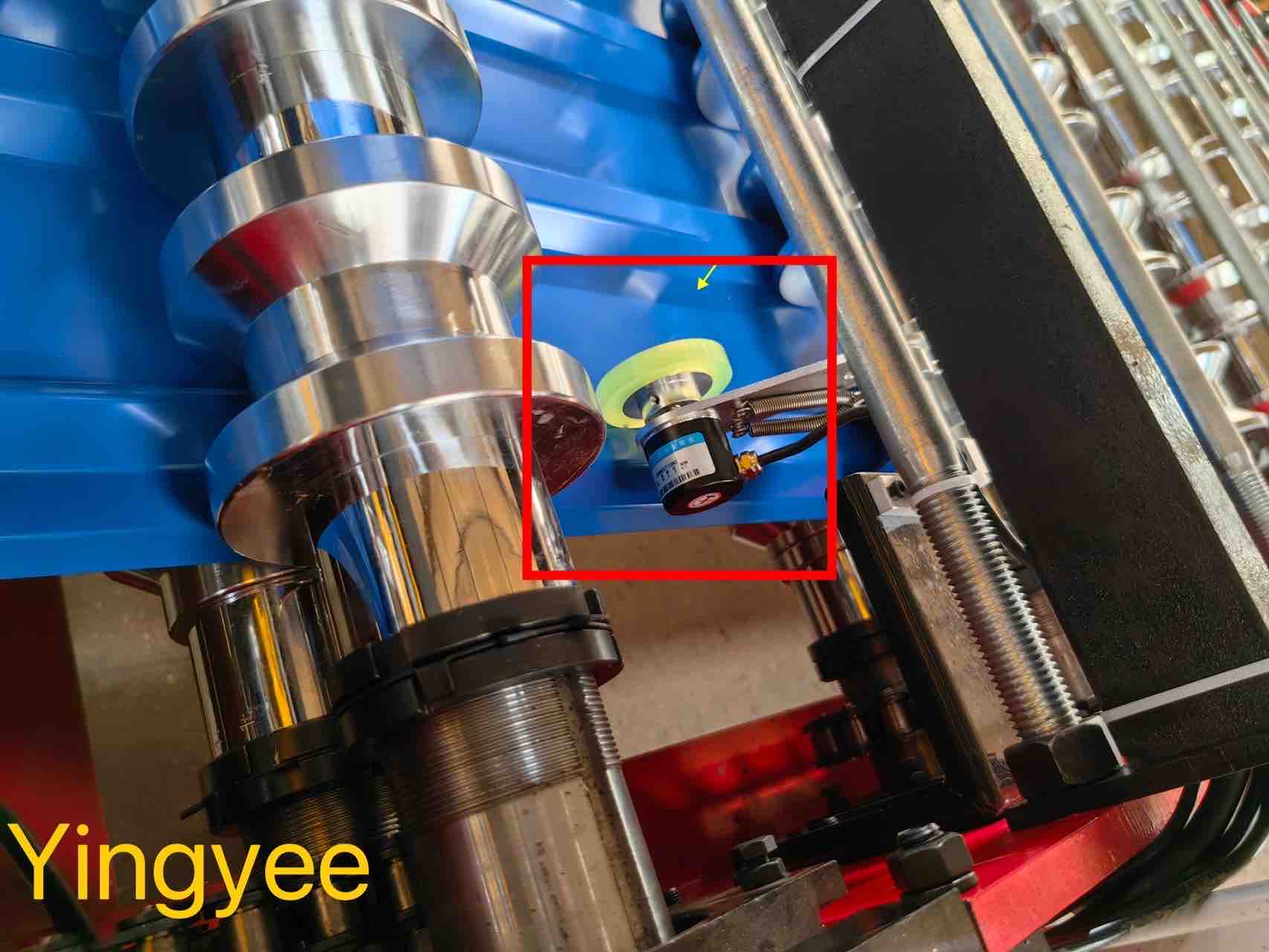

Authoritative voices in the construction equipment industry often highlight the importance of machine reliability and operational trustworthiness. Customized roll forming machines are equipped with advanced automation and control systems that ensure high-speed production without sacrificing quality. This development not only enhances productivity but also offers operators the confidence needed to manage large-scale production demands. The integration of AI and machine learning into these machines is another step towards ensuring precise operational parameters, reducing error margins, and boosting the overall trust in automated manufacturing systems.

customized angle stud and track/drawall/c channel/main channel/wall angle roll forming machine

Another compelling aspect of these machines is their adaptability to different market needs and regulations across the globe. The ability to produce region-specific construction materials compliant with local standards is a testament to the machines' versatility and the expertise of manufacturers behind them. Whether it’s the seismic requirements in Japan or extreme weather conditions in Scandinavian countries, these machines produce tailored solutions to meet diverse environmental challenges.

An experience shared by many leaders in the construction industry is the use of customized roll forming machines to accelerate project timelines without compromising on quality. The efficiency brought forth by these machines aids in quick assembly and installation, significantly reducing labor costs and improving project turnaround times. This experience underscores the importance of deploying highly technical and specialized equipment in today's fast-paced construction environment.

In conclusion,

the role of customized angle stud and track, drywall C channel, main channel, and wall angle roll forming machines is not merely functional but transformative. Their ability to integrate cutting-edge technology with industry demands positions them as essential elements in the toolset of modern construction projects. The expertise they offer, combined with their adaptability and precise performance, ensures that construction industry players can rely on them for consistently high-quality outputs. As industry leaders continue to seek efficiency, sustainability, and adaptability, these machines offer formidable solutions that drive excellence in construction methodology.