The Color Stone Coated Roof Tile Production Line An Overview

The roofing industry has witnessed remarkable advancements over the years, and one of the most significant developments is the introduction of color stone coated roof tiles. These tiles offer not only aesthetic versatility but also exceptional durability and functionality. The production line for these tiles is a complex process that combines advanced technology with high-quality materials, ensuring a final product that meets the demands of modern construction.

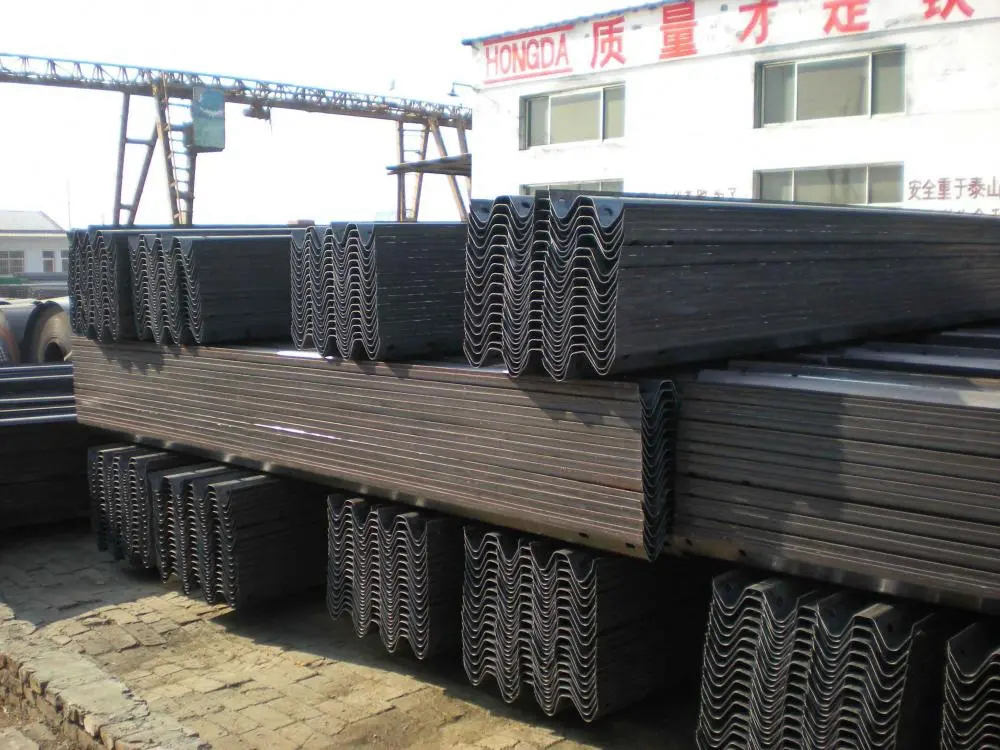

The production of color stone coated roof tiles begins with the selection of a strong substrate, typically made from Galvalume steel or aluminum. This substrate serves as the backbone of the tile, providing structural integrity and strength. The choice of material is crucial, as it affects the overall performance of the tile, including its resistance to weathering and corrosion.

Once the substrate is prepared, the production process moves on to the application of a layer of acrylic resin. This resin not only enhances the bonding of the stone chips but also provides an additional layer of protection against the elements. The importance of using high-quality acrylic resin cannot be overstated, as it directly influences the longevity and functionality of the final product.

The next step involves the application of color stone chips to the wet acrylic surface. These chips are typically made from natural stone particles that are selected for their durability and colorfastness. The use of varied colors not only adds to the aesthetic appeal of the tiles but also mimics the look of more traditional roofing materials like slate or clay. The choice of colors and textures allows homeowners and builders to select the perfect tiles that will complement their architectural designs.

After the stone chips are applied, the tiles go through a curing phase. This process involves heating the tiles to ensure that the resin and stone chips bond effectively. Proper curing is vital to achieving the desired hardness and resilience of the tiles. Following this, the tiles undergo quality control testing to ensure that they meet industry standards for performance and durability.

Once the production line has completed the manufacturing process, the tiles are ready for packaging and distribution. The final product is not only lightweight and easy to install but also environmentally friendly, as the materials used are often sourced from sustainable resources.

In conclusion, the production line for color stone coated roof tiles is a sophisticated process that combines innovative technology with quality materials. It reflects the industry's commitment to providing durable, aesthetically pleasing, and sustainable roofing solutions. As the demand for high-performance roofing materials continues to rise, color stone coated roof tiles stand out as a leading choice for builders and homeowners alike, offering a perfect blend of beauty and functionality. This production line not only meets the needs of modern architecture but also ensures that structures remain protected against the elements for years to come.