Nga tikanga whakaputa taketake o nga taputapu

Nga tikanga hanga taputapu:

1 The equipment covers an area: 30×3×2 (length×width×height) meters.

2 Te huarahi whangai taputapu: maui ki roto, matau ki waho.

3 Tawhā ngaohiko 380, 50Hz, 3 wahanga.

4 Air source: the flow rate is 0.5m³/Min; the pressure is 0.7MPa.

5 Hinu waipēhi: 46# hinu waipēhi.

6 Hinu taputapu: 18# hinu taputapu hiako.

Tawhā hangarau matua o te taputapu

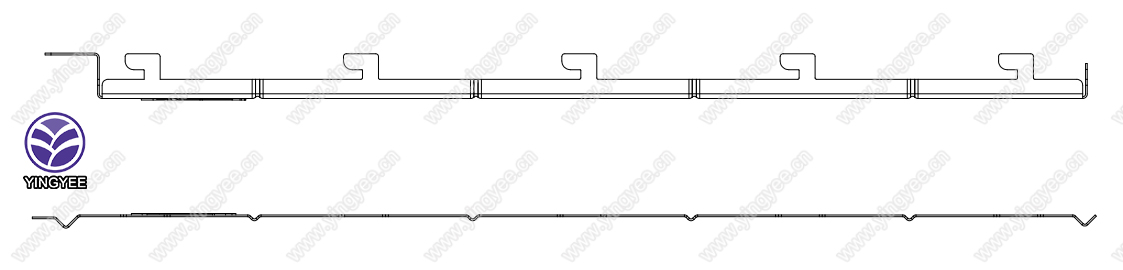

1 Rolled strip width: ≤775mm

2 Te matotoru o te takai hurihuri: 0.6mm/0.9mm

3 Rolled strip material: cold-rolled steel strip yield limit σs≤260Mpa

4 Roll material: Cr12, quenched HRC56°-60°

5 Te tere tere: 0 ~ 12m / min, te tere ipurangi 0-6 M / min

6 Te roa o nga mea mahi kua hurihia: he tautuhinga kore-kaiwhakamahi

7 Katoa te kaha whakauru o nga taputapu: mo te 30KW.

Tukatuka:

tātuhi:

Taketake whakaritenga

|

Kao. |

Nga taonga |

Spec: |

|

1 |

Rauemi |

1. Thickness: 0.6mm 2. Input width: max. 462mm 3. material: Cold rolled steel strip; yield limit σs≤260Mpa |

|

2 |

Power supply |

380V, 60Hz, 3 phase |

|

3 |

Capacity of power |

1. Total power: about 20kW 2. Punchine system power: 7.5kw 3. Roll forming machine power: 5.5kw 4. Track cutting machine power: 5kw |

|

4 |

Te tere |

Tere Raina: 0-9m/min(tae atu ki te whiu) Te hanga tere: 0-12m / min |

|

5 |

Hinu waikura |

46# |

|

6 |

Hinu taputapu |

18# Hyperbolic gear oil |

|

7 |

Ahu |

Approx.(L*W*H) 20m×2m×2m |

|

8 |

Nga turanga roera |

Roll forming machine for Fundo 2F: 17 rollers Kotahi te roera taapiri Fundo 1F: 12 roera |

|

9 |

Rauemi o nga roera |

Cr12, quenched HRC56°-60° |

|

10 |

Te roa o te taonga mahi kua hurihia |

Tautuhinga koreutu a te kaiwhakamahi |

|

11 |

Kāhua tapahi |

Hydraulic Tracking cut |