China Double Layer Roll Forming Machine A Comprehensive Overview

In recent years, the construction and manufacturing industries have seen significant advancements, particularly in roofing and wall panel systems. One of the most innovative solutions is the double layer roll forming machine, a sophisticated piece of machinery designed to optimize production efficiency, reduce costs, and enhance the quality of metal products. This article delves into the features, benefits, and applications of the double layer roll forming machine, with a focus on its significance in China’s manufacturing landscape.

What is a Double Layer Roll Forming Machine?

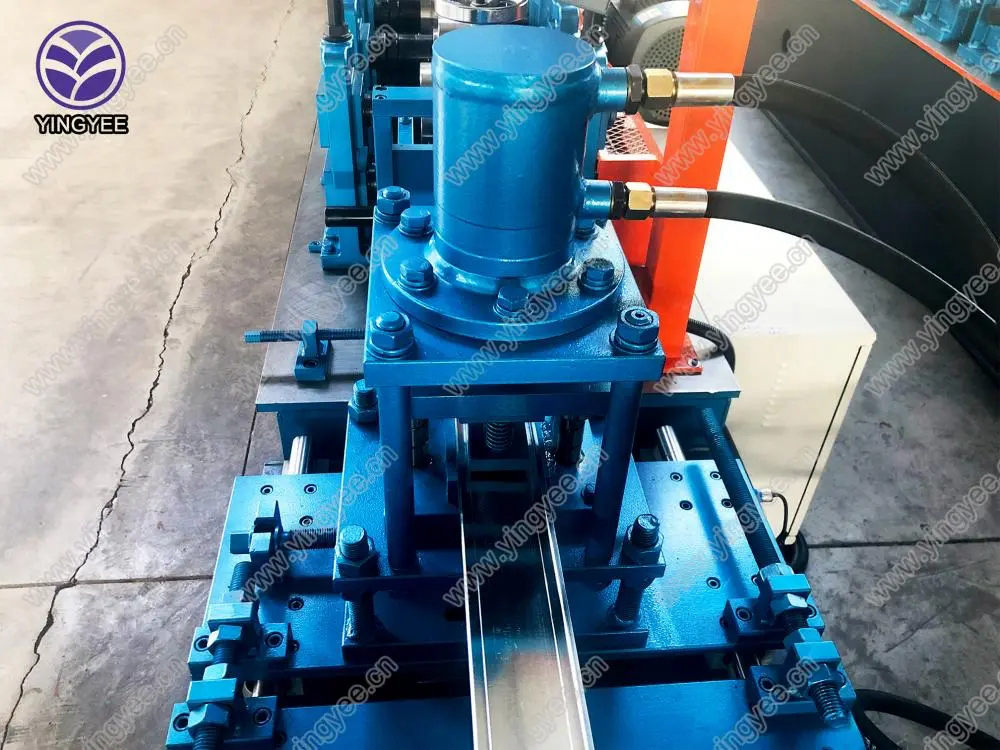

A double layer roll forming machine is a versatile piece of equipment that allows for the simultaneous production of two different profiles or layers of metal sheets. The machine operates by feeding metal coils through a series of rollers, which gradually shape the material into the desired profiles. This technology is particularly beneficial for producing roofing sheets, wall panels, and various other construction components.

In essence, a double layer roll forming machine combines two individual roll forming processes into one, thus achieving higher output with lower operational costs. The machine can be customized to accommodate a wide range of materials, including galvanized steel, aluminum, and stainless steel, making it suitable for various applications in construction and industrial sectors.

Advantages of Double Layer Roll Forming Machines

1. Cost Efficiency By producing two different profiles in a single pass, manufacturers can significantly reduce their operational costs. This includes savings on labor, material handling, and equipment maintenance.

2. Space-Saving Design Traditional roll forming operations often require multiple machines for different profiles, leading to increased floor space requirements. In contrast, a double layer roll forming machine occupies less space while delivering the same or even higher production levels.

3. Versatility These machines can be designed to produce an array of profiles, ranging from simple corrugated sheets to more complex shapes. This adaptability makes them ideal for manufacturers looking to diversify their product offerings without investing in multiple machines.

4. High Efficiency Double layer roll forming machines are engineered for high-speed production, allowing manufacturers to meet increasing market demands without compromising on quality. This high efficiency is particularly crucial in today’s fast-paced construction industry.

5. Enhanced Quality The precision of modern roll forming technology ensures that the finished products exhibit superior dimensional accuracy and surface quality. This is vital for applications where visual appeal and structural integrity are paramount.

Applications of Double Layer Roll Forming Machines

Double layer roll forming machines are utilized across various industries, notably in construction and manufacturing. Their ability to produce high-quality roofing sheets and wall panels makes them an indispensable tool in building projects. Common applications include

- Residential and Commercial Roofing The ability to produce aesthetically pleasing and robust roofing solutions is essential in both residential and commercial construction. Double layer roll forming machines can create profiles that enhance the architectural beauty of buildings while providing superior weather resistance.

- Industrial Facilities The demand for durable wall panels and insulated roofing systems in factories and warehouses has led to increased reliance on double layer roll forming machines. These structures often require materials that can withstand harsh environments, making the quality produced by these machines crucial.

- Agricultural Buildings The agricultural sector also benefits significantly from double layer roll forming technology. Farmers and agricultural producers require reliable, cost-effective solutions for constructing storage sheds, barns, and greenhouses.

The Future of Double Layer Roll Forming Machines in China

As China continues to transition toward more advanced manufacturing practices, the adoption of double layer roll forming machines is expected to rise sharply. The country’s commitment to innovation and efficiency in production aligns well with the capabilities of this technology. Manufacturers in China are increasingly investing in automation and smart production techniques, which will further enhance the performance and output of double layer roll forming machines.

In conclusion, the China double layer roll forming machine represents a significant leap forward in production technology for the construction and manufacturing industries. Its ability to streamline operations, reduce costs, and produce high-quality products positions it as a critical asset in the ever-evolving landscape of industrial manufacturing. As demand continues to grow, the impact of this technology is likely to resonate globally, transforming how metal products are manufactured and utilized in the years to come.