The Importance of Steel Curving Unistrut Roll Forming Machines

In the world of construction and manufacturing, efficiency and precision are paramount. One of the innovative solutions that have emerged to meet these demands is the steel curving unistrut roll forming machine. This equipment is revolutionizing the way structural steel components are manufactured, providing numerous benefits in terms of productivity, material utilization, and overall quality.

Understanding Roll Forming Technology

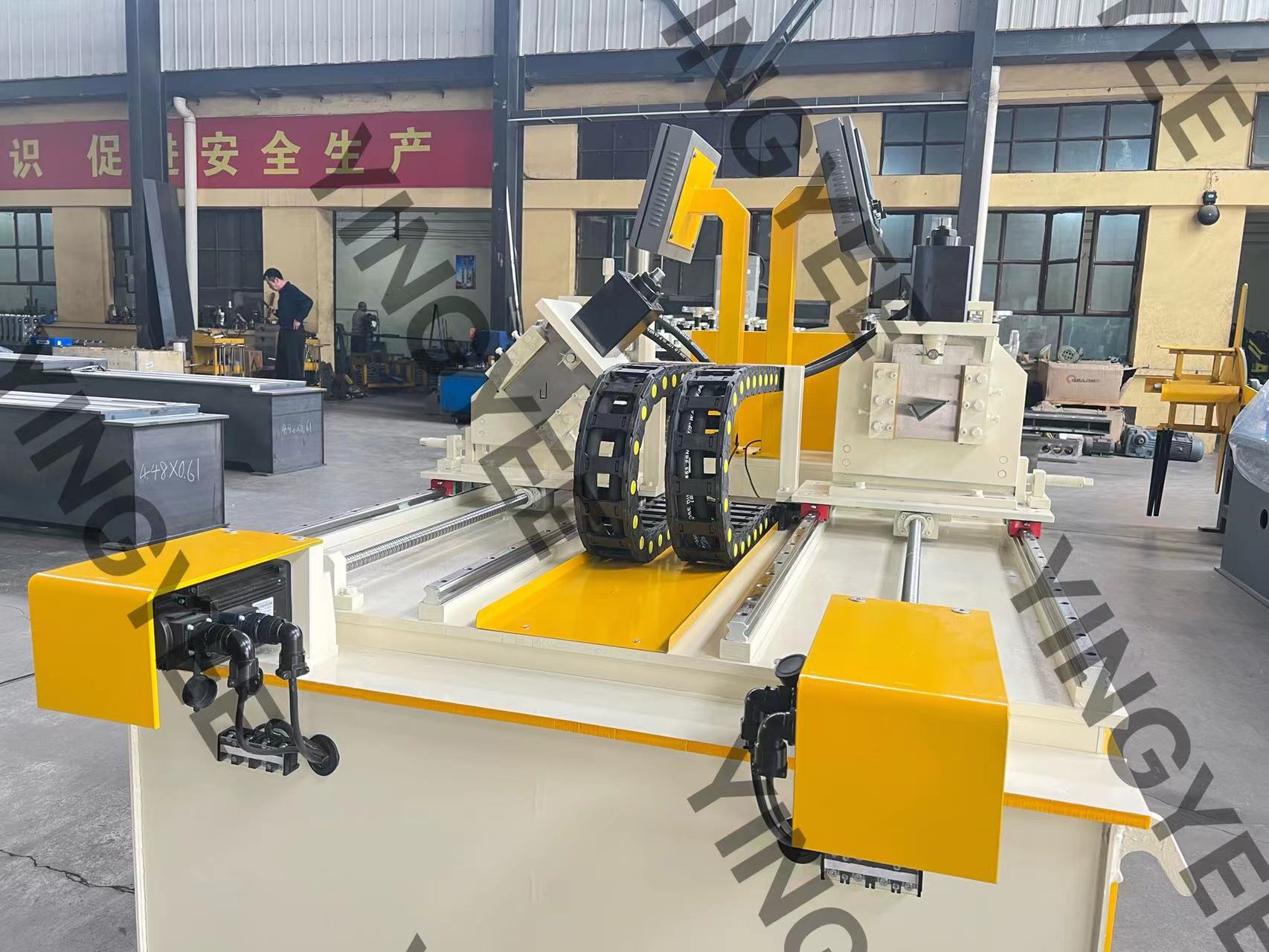

Roll forming is a process that involves continuously feeding a long strip of metal, usually in coil form, through a series of rolling mills that progressively shape it into a desired cross-section. This method is especially effective for creating structural elements, such as unistrut channels, which are used widely in construction for supporting various types of equipment, piping, and electrical installations. The steel curving unistrut roll forming machine takes this technology a step further by allowing for the precise curving of unistrut profiles, enabling a smooth and efficient construction process.

Key Advantages

1. Customization The primary advantage of steel curving unistrut roll forming machines is the ability to customize the shapes and sizes of the unistrut profiles. This flexibility means manufacturers can meet specific project requirements without the need for extensive retooling or design alterations. Customization is vital in today’s construction environment, where unique architectural designs are in high demand.

2. Material Efficiency Traditional methods of producing curved steel components often result in significant material waste due to cutting and shaping. Roll forming minimizes waste as the process utilizes the material more efficiently. The continuous operation of roll forming machines ensures that almost every millimeter of steel is used effectively, thus reducing costs and environmental impact.

3. Speed and Automation Modern steel curving unistrut roll forming machines are equipped with advanced automation technologies that facilitate high-speed production. This enhances productivity by reducing the time required to manufacture each component. Moreover, automation lessens the need for manual labor, which can help lower labor costs in the long run.

4. Quality and Consistency The precision of roll forming leads to enhanced quality and consistency in the finished products. With tighter tolerances and less human error, steel components produced from roll forming machines have superior strength and integrity. This reliability is crucial when these components are used in structural applications, where safety and durability are paramount.

5. Reduced Labor Costs Automating the roll forming process reduces the dependency on manual labor, allowing companies to allocate resources more efficiently. This shift leads to substantial savings in labor costs and enhances the overall safety of the workplace, as fewer workers are exposed to potential hazards associated with manual fabrication.

Conclusion

In conclusion, steel curving unistrut roll forming machines represent a significant advancement in the construction and manufacturing industries. Their ability to produce high-quality, customized steel components efficiently and sustainably makes them an indispensable tool for modern manufacturers. As construction projects evolve to embrace more innovative designs, the role of advanced machinery like steel curving unistrut roll forming machines will only continue to grow, paving the way for a more efficient and environmentally friendly approach to construction.