The Steel Bar Lattice Girder Welding Machine A Revolutionary Tool in Construction

In the modern construction industry, efficiency and precision are paramount. Steel bar lattice girders play a critical role in providing structural support for buildings, bridges, and various infrastructures. The introduction of specialized machinery, such as the steel bar lattice girder welding machine, marks a significant advancement in the process of constructing these essential components.

The steel bar lattice girder is a framework made by welding steel bars into a grid-like structure. This design offers both strength and flexibility, making it ideal for a variety of applications. Traditionally, the process of creating these girders was labor-intensive and time-consuming, involving manual welding and assembly. However, with the advent of the steel bar lattice girder welding machine, this process has been revolutionized.

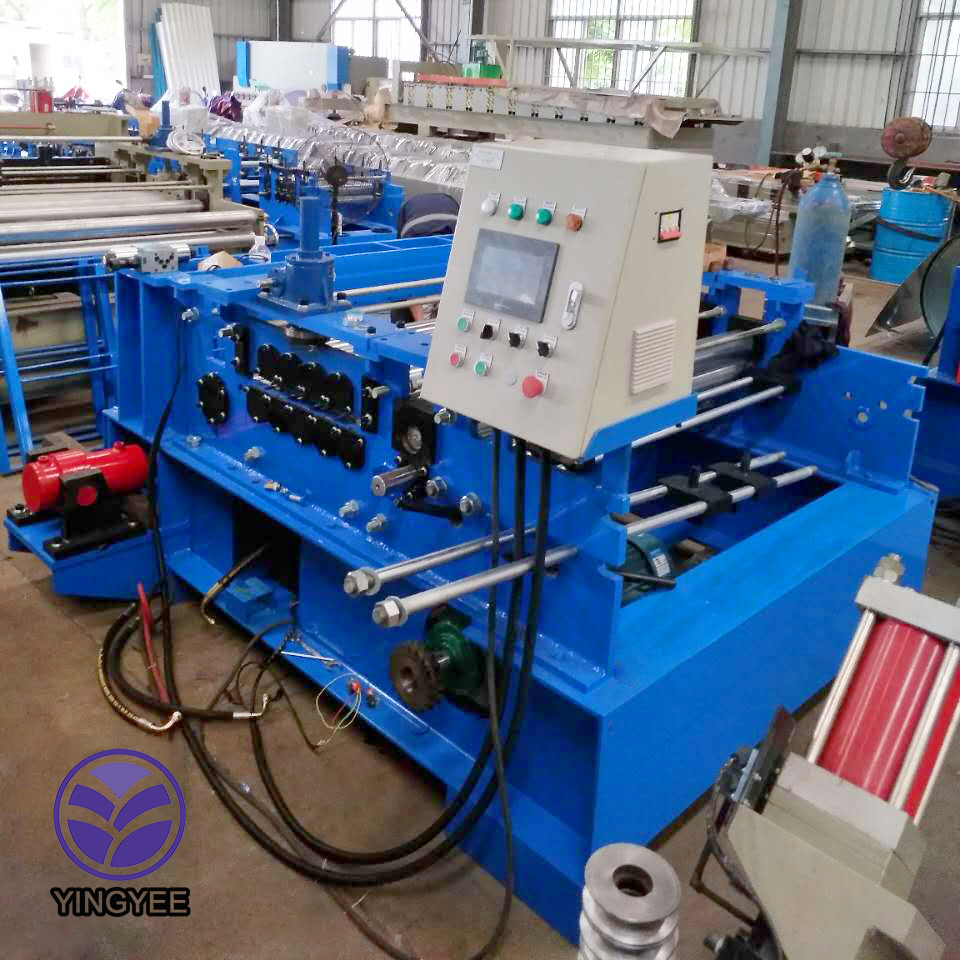

The welding machine automates the joining of the steel bars, ensuring consistency and precision in the welding process. Equipped with advanced technology, these machines can adjust parameters such as temperature, speed, and pressure to achieve optimal results. This automation not only speeds up production time but also reduces the likelihood of human error, resulting in high-quality welds that meet stringent industry standards.

One of the most significant advantages of the steel bar lattice girder welding machine is its ability to increase productivity. With automated systems, construction companies can produce a higher volume of girders in a shorter time frame. This is particularly beneficial for large-scale projects where delays can lead to increased costs. The high output rates mean that construction schedules can be met more efficiently, ultimately leading to faster project completion.

Moreover, the use of welding machines enhances safety on construction sites. Manual welding poses various risks, including burns, inhalation of fumes, and potential accidents due to improper handling of tools. By mechanizing the welding process, risks associated with manual labor are significantly diminished, creating a safer working environment for employees.

In addition to enhancing efficiency and safety, the steel bar lattice girder welding machine contributes to sustainability in construction. The precision of automated welding ensures that materials are used optimally, minimizing waste. Additionally, by improving the quality of welds, the lifetime of girders is extended, leading to more durable structures that require less maintenance over time.

The innovation does not stop with the machines themselves. Many manufacturers are now integrating smart technology into these welding machines, allowing for real-time monitoring and data collection. This capability enables companies to analyze production processes, identify areas for improvement, and ultimately optimize their operations.

In conclusion, the steel bar lattice girder welding machine represents a significant leap forward in the construction industry. By automating the welding process, it greatly enhances productivity, improves safety, and promotes sustainability. As the demand for efficient and resilient construction solutions continues to rise, the adoption of such advanced machinery will undoubtedly play a pivotal role in shaping the future of infrastructure development. Embracing these technologies not only streamlines operations but also contributes to the creation of safer and more sustainable built environments.