(purlin roll forming machine for sale)

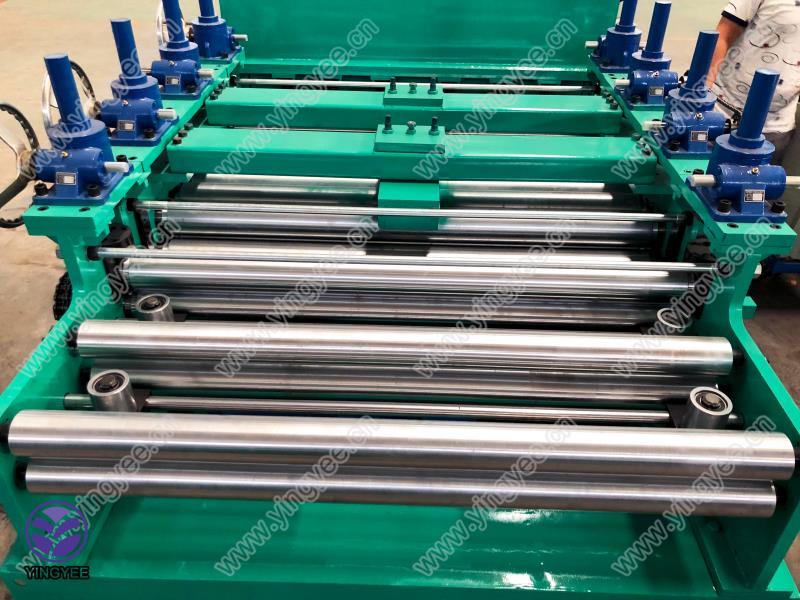

The construction industry requires precision-engineered solutions for structural components like C/Z purlins. Modern purlin roll forming machines deliver production speeds of 15-25 meters per minute while maintaining ±0.5mm dimensional accuracy. Unlike traditional fabrication methods, these automated systems reduce material waste by 15-20% through optimized coil feeding mechanisms.

Advanced models integrate servo-driven control systems with real-time thickness monitoring (10-1000μm resolution). Key innovations include:

| Brand | Max Speed (m/min) | Material Thickness | Price Range | Warranty |

|---|---|---|---|---|

| AlphaFormer Pro | 28 | 0.3-3.5mm | $85,000-$120,000 | 5 years |

| SteelMaster Ultra | 22 | 0.5-4.0mm | $65,000-$95,000 | 3 years |

| FormTech Basic | 18 | 0.7-2.5mm | $45,000-$75,000 | 1 year |

Custom configurations address specific project needs:

Recent projects demonstrate 30% cost reduction when combining used purlin roll forming machines with retrofit IoT monitoring packages.

A 2023 warehouse project utilized three purlin machines to produce 12,000 linear meters of C-section steel weekly. Key metrics:

Proper maintenance extends machine lifespan beyond 15 years:

Evaluate production requirements against these critical factors:

Premium purlin roll forming machines for sale typically demonstrate 30% higher efficiency in load-bearing tests compared to entry-level alternatives.

(purlin roll forming machine for sale)

A: Reputable manufacturers, industrial equipment suppliers, and specialized online marketplaces like Alibaba or TradeKey offer new and used purlin roll forming machines. Always verify seller credentials and machine specifications before purchasing.

A: Used machines are cost-effective, ideal for smaller budgets or short-term projects. Ensure the equipment has proper maintenance records and minimal wear to avoid hidden repair costs.

A: Request quotes from multiple suppliers, factoring in machine capacity, automation features, and warranty terms. Compare both new and used options to find the best value.

A: Inspect the machine's structural integrity, motor condition, and roll tooling wear. Request production test results and confirm spare parts availability to ensure operational reliability.

A: Most manufacturers offer 1-3 years of warranty covering parts and labor. Review warranty terms thoroughly, including exclusions and post-purchase support services.