The Highway Guardrail Making Machine Factory A Pillar of Road Safety

In the realm of transportation infrastructure, highway guardrails play a pivotal role in ensuring the safety of road users. A vital component in the manufacturing of these essential safety features is the machinery used to produce them. The highway guardrail making machine factory stands as a cornerstone of this industry, showcasing advanced technology and engineering ingenuity.

Highway guardrails serve as a protective barrier along roads and highways, designed to prevent vehicles from veering off the road and potentially causing accidents. Given their importance, it is critical that these barriers are manufactured to the highest standards of quality and resilience. This is where the significance of guardrail making machines comes into play. These specialized machines automate the production process, ensuring that each piece of guardrail is crafted with precision.

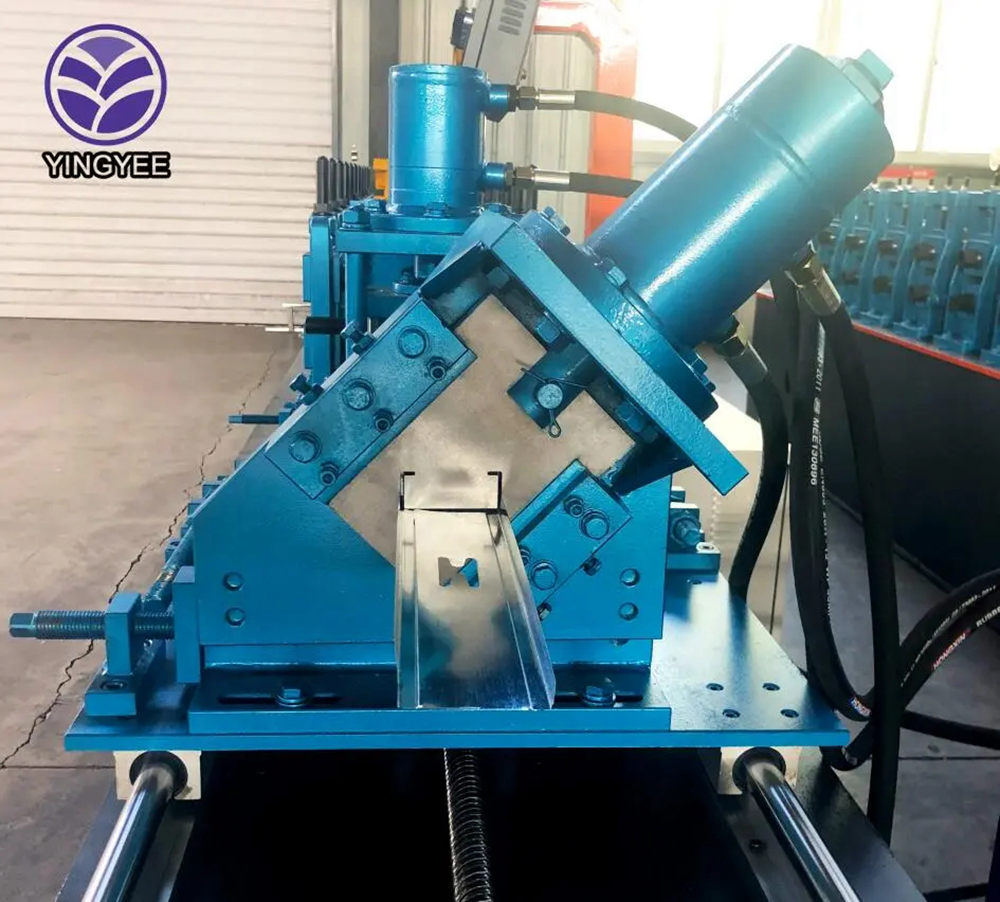

The manufacturing process begins with the selection of raw materials, typically high-strength steel or aluminum alloys, chosen for their durability and stability. The highway guardrail making machine utilizes advanced bending, cutting, and welding techniques to shape these materials into the required guardrail designs. Through automation, the process not only enhances speed and efficiency but also minimizes human error, resulting in a consistently high standard of production.

One of the key features of modern guardrail making machines is their versatility. These machines can produce various types of guardrails, including W-beam, thrie-beam, and cable systems, allowing manufacturers to meet diverse specifications and safety standards. Furthermore, the integration of computer numeric control (CNC) technology has revolutionized the manufacturing process. CNC machines can precisely execute complex designs, thus expanding the potential for customized guardrail solutions tailored to specific geographic or regulatory needs.

The factory environment also reflects the commitment to safety and quality assurance. Comprehensive quality control measures are implemented at every stage of production, from raw material inspection to final testing of the finished products. This diligence ensures that the guardrails not only meet but often exceed regulatory standards set by transportation authorities.

In addition to producing guardrails, these factories often serve a larger purpose by contributing to the economy. They create jobs, support local industries, and promote technological advancements. The demand for reliable highway guardrails is constantly rising due to increasing vehicular traffic and infrastructure development. This trend drives innovation within the guardrail manufacturing sector and fosters a competitive marketplace where efficiency and safety are paramount.

Moreover, as environmental concerns continue to grow, many factories are now adopting sustainable practices in their operations. This includes using recycled materials in production and minimizing waste through efficient manufacturing processes. Emphasizing sustainability, these initiatives not only protect the environment but also appeal to the growing market of eco-conscious consumers and regulatory bodies.

In conclusion, the highway guardrail making machine factory is more than just a production facility; it is a critical player in enhancing road safety and promoting innovation within the construction industry. By combining advanced technology, rigorous quality control, and sustainable practices, these factories contribute significantly to protecting lives on the road. As infrastructure continues to evolve, the role of guardrail manufacturing will remain a vital element of safe transportation systems worldwide.