High-Speed Roller Door Panels Forming Machine Revolutionizing Industrial Doors

In today's fast-paced industrial environment, efficiency and security are paramount. One innovation that has significantly transformed the industry is the high-speed roller door panels forming machine. This advanced equipment not only enhances production rates but also ensures the quality and durability of roller door panels.

The Importance of Roller Doors

Roller doors are an integral part of commercial and industrial spaces. They provide a secure barrier to protect property, equipment, and personnel from unauthorized access and environmental elements. Moreover, their ability to open and close quickly minimizes downtime in busy operations, making them ideal for warehouses, distribution centers, and manufacturing facilities. The quality of these doors relies heavily on the precision of the manufacturing process, which is where high-speed roller door panels forming machines come into play.

Features of High-Speed Roller Door Panels Forming Machines

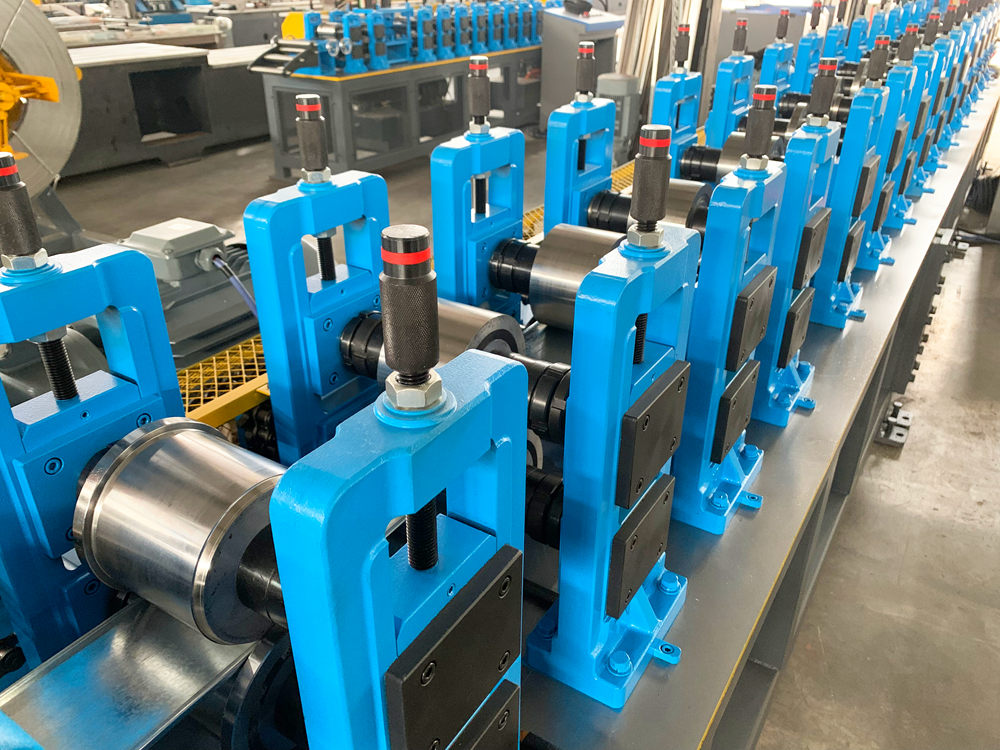

These machines are equipped with state-of-the-art technology that allows them to produce door panels with high efficiency and consistency. One of their standout features is the rapid forming process. Traditional manufacturing methods can be time-consuming and labor-intensive, often resulting in variations in product quality. However, high-speed machines utilize automated systems that can form multiple panels simultaneously, significantly reducing production time.

Another key feature is the precision engineering of these machines. High-speed roller door panel forming machines are designed to deliver consistent thickness, width, and materials, allowing for the production of robust panels that meet industry standards. This precision not only enhances the overall strength of the doors but also reduces waste, making the process more environmentally friendly.

Benefits for Businesses

Investing in a high-speed roller door panels forming machine presents numerous advantages for manufacturers. Firstly, the increase in production speed leads to higher output, enabling businesses to meet escalating demands without compromising quality. This can give companies a competitive edge in the market, as they can fulfill orders more promptly.

Additionally, the automated systems within these machines reduce labor costs, as fewer personnel are needed to operate and supervise the manufacturing process. This allows factory operators to allocate human resources to other critical areas of production, enhancing overall operational efficiency.

Conclusion

In summary, high-speed roller door panels forming machines represent a significant advancement in the manufacturing of industrial doors. Their ability to produce high-quality panels quickly and efficiently meets the increasing demand in the market while providing businesses with a cost-effective solution. As more companies recognize the importance of efficiency and security, the adoption of this technology is likely to become even more prevalent. The future of industrial door manufacturing is undoubtedly geared toward high-speed production methods, ensuring that businesses can operate smoothly while keeping their properties safe and secure.

In conclusion, embracing high-speed roller door panels forming machines is not just a step towards modernization; it is an investment in the future of industrial operations.