Understanding ERW Steel Square Pipe Making Machines

Electric Resistance Welding (ERW) steel square pipe making machines play a vital role in the steel pipe industry. These advanced machines are designed to produce high-quality square and rectangular steel tubes through a process that offers efficiency and precision. As industries continue to demand durable and versatile piping solutions, the importance of ERW technology in steel pipe production becomes increasingly evident.

The Working Principle of ERW Steel Pipe Making Machines

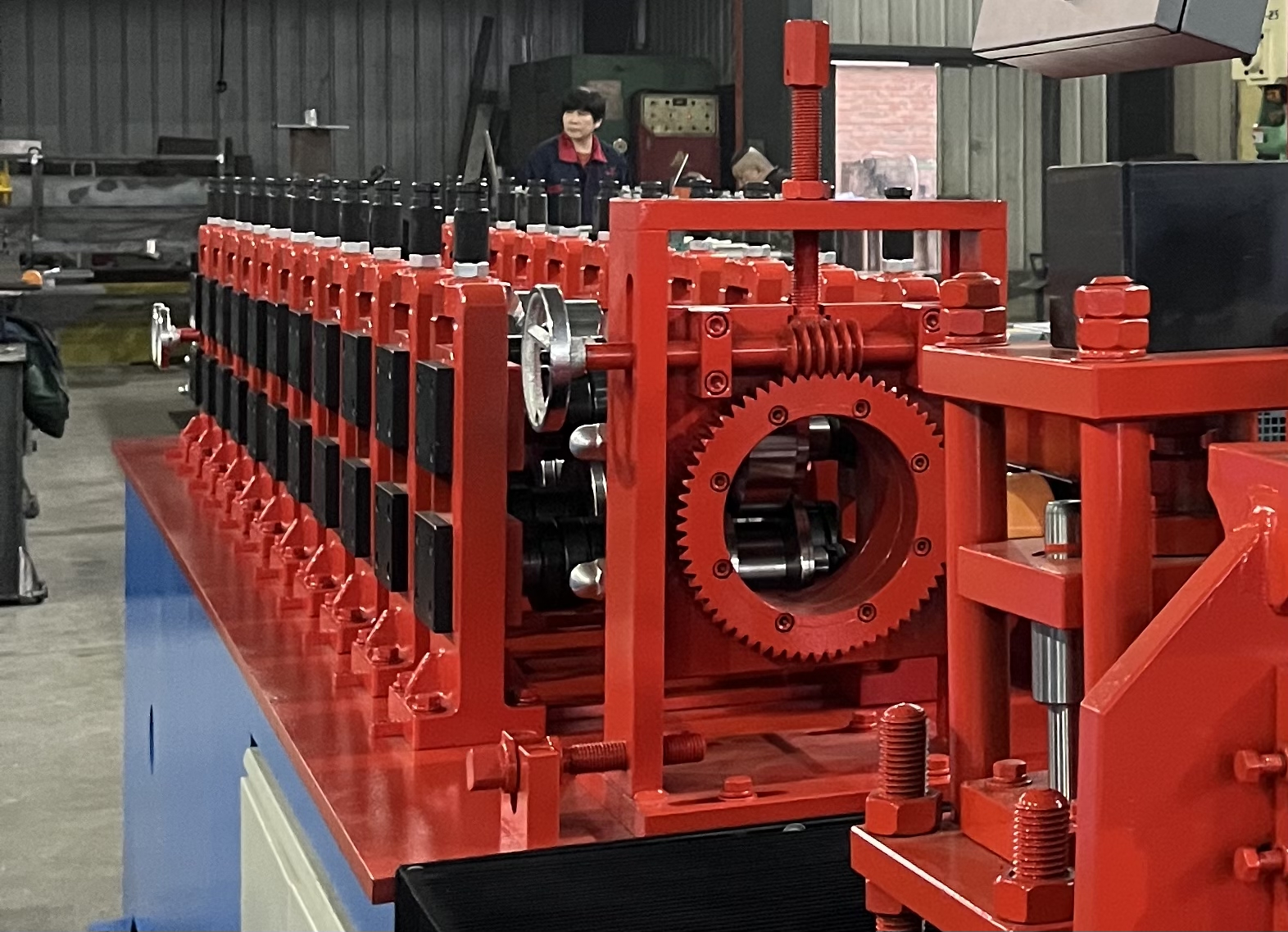

The ERW process involves the use of high-frequency electric currents to weld steel strips or sheets together. The machine typically starts with loading the steel coils, which are unwound and fed into the forming unit. The strip passes through a series of rollers that gradually shape it into a square or rectangular profile. As the edges of the strip come together, the electric resistance welding process is initiated.

The heat generated by the electric current causes the edges of the strip to melt slightly, allowing them to fuse together under pressure. This method ensures a strong, continuous seam that is critical for the structural integrity of the finished product. The welded tube is then cooled, cut to the desired length, and may undergo additional processing such as surface treatment or coating to enhance durability and corrosion resistance.

Advantages of ERW Steel Square Pipe Making Machines

One of the primary advantages of ERW technology is its efficiency. The machines can produce a vast number of pipes in a relatively short time, making them ideal for high-demand applications. Additionally, the welding process is consistent, resulting in high-quality seams that meet industry standards.

Moreover, ERW machines require relatively lower amounts of energy compared to other welding techniques. This makes them not only cost-effective but also more environmentally friendly, an important consideration as industries seek to adopt sustainable practices.

The versatility of ERW machines is another key benefit. They can be adjusted to produce various sizes and thicknesses of square and rectangular pipes, catering to different requirements across industries such as construction, automotive, and manufacturing. This flexibility allows manufacturers to respond quickly to market changes and customer demands.

Applications of ERW Steel Square Pipes

ERW steel square pipes have a wide range of applications due to their strength and structural integrity. They are commonly used in building and construction, serving as frames for structures, supports for roofs, and conduits for electrical wiring. In the automotive industry, these pipes are utilized in manufacturing components such as vehicle frames and exhaust systems.

Another significant application is in the furniture industry, where ERW steel square pipes are used to create durable and aesthetically pleasing furniture pieces. Their uniform shape and strength make them ideal for creating modern designs while ensuring longevity.

Future Trends in ERW Technology

As technology advances, the future of ERW steel square pipe making machines looks promising. Innovations in automation and robotics are likely to enhance production efficiency and reduce operational costs. Integration with smart manufacturing solutions will enable real-time monitoring of the production process, improving quality control and minimizing waste.

Furthermore, as sustainability continues to be a primary focus for industries worldwide, improvements in materials and processes that reduce energy consumption and waste in ERW manufacturing will become increasingly critical. Research into advanced steel alloys may also lead to the development of lighter yet stronger pipes, expanding their applications further.

Conclusion

In summary, ERW steel square pipe making machines represent a crucial component of modern manufacturing processes. With their ability to produce high-quality, durable pipes efficiently, they serve various industries while supporting sustainable practices. As technology evolves, these machines will undoubtedly continue to improve, meeting the growing demands of the market and paving the way for innovative applications in the future. The ongoing advancements in this field will not only enhance production capabilities but also ensure that ERW technology remains at the forefront of the steel pipe industry.