The Benefits of Large Span Roll Forming Machines with Bending Capabilities for Nut and Bolt Production

In the ever-evolving world of manufacturing, efficiency and precision are paramount, especially in industries that require the production of hardware components like nuts and bolts. One of the advancements enhancing productivity in this sector is the large span roll forming machine combined with a bending machine. This sophisticated equipment plays a crucial role in optimizing the manufacturing processes, enabling the production of high-quality fasteners with minimal waste.

Roll forming is a highly efficient process that shapes metal sheets into desired profiles through continuous bending, which is particularly advantageous for the mass production of industrial components. When it comes to nuts and bolts, where dimensional accuracy and uniformity are critical, large span roll forming machines provide the scale and precision necessary to meet these demands.

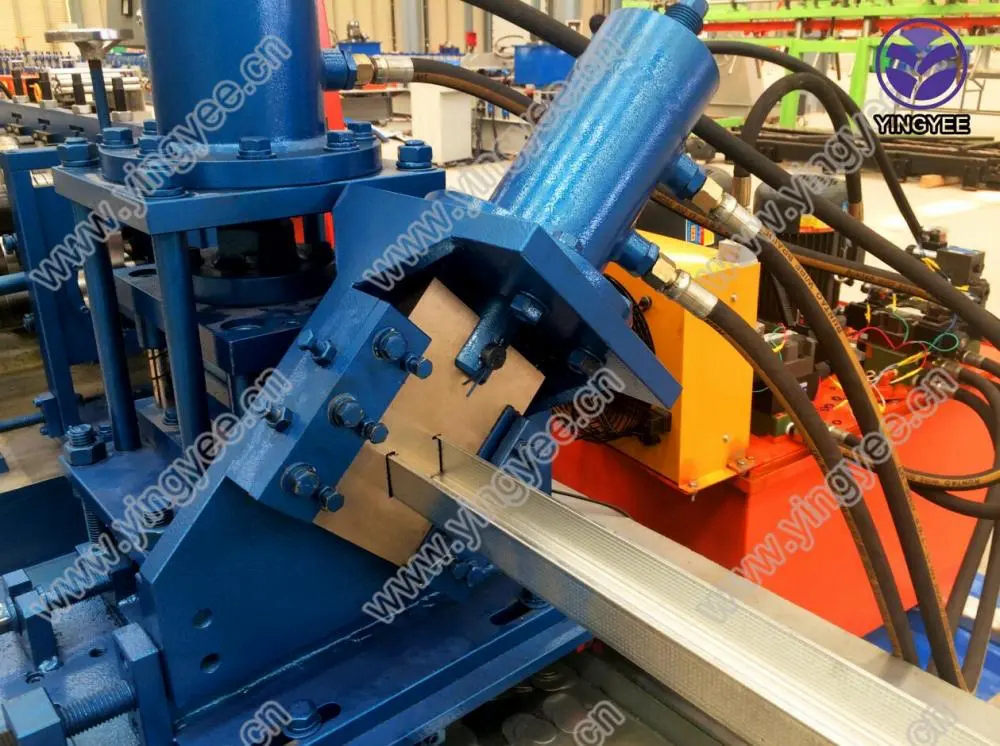

The integration of bending capabilities into these machines further enhances their utility. Typically, nuts and bolts require specific angles and dimensions for proper functionality. Traditional methods might involve separate machines for forming and bending, leading to increased production time and costs. However, a large span roll forming machine with integrated bending functionality streamlines the entire process, allowing manufacturers to form, cut, and bend materials in one seamless operation.

One of the key benefits of large span roll forming machines is their ability to work with various types of materials, including steel, aluminum, and alloyed metals. This versatility makes it easier for manufacturers to adapt to changing market demands, whether they need to produce standard fasteners or custom components for specific applications. The advanced technology used in these machines ensures consistent output quality, reducing scrap rates and enhancing profitability.

Moreover, the capacity of large span roll forming machines to handle larger widths and spans means they can produce bigger components without compromising on quality. This feature is particularly relevant for industries such as construction and automotive, where strong and reliable fasteners are essential. The precision in rolling and bending capabilities guarantees that the end products will meet rigorous industry standards and specifications.

Efficiency is another significant advantage. These machines are designed for high-speed production, which results in shorter lead times and improved responsiveness to market needs. Fast and accurate production not only satisfies customer demands but also allows manufacturers to compete effectively in a global marketplace. Additionally, advances in automation technology, such as programmable controls and real-time monitoring systems, enhance overall operational efficiency, reducing labor costs, and minimizing human error.

In conclusion, the incorporation of large span roll forming machines with bending capabilities represents a significant leap forward in the production of nuts and bolts. Their ability to provide high-quality, precision-engineered products efficiently makes them invaluable assets in the manufacturing landscape. As industries continue to evolve, adopting such advanced machinery will be essential for companies looking to maintain competitiveness and meet the demands of modern engineering challenges. Investing in these technologies not only improves production lines but also supports sustainable practices by reducing material waste and energy consumption.