The advancement in industrial manufacturing has underscored the need for precise and efficient machinery. Within this realm, the straighten and cutting machine for steel coil stands out as an indispensable asset for the modern factory. Drawing from years of experience and expertise in industrial machinery and steel processing, our evaluation dives into why this equipment is not only crucial but revolutionary.

Steel coils, the fundamental building blocks for diverse industries such as construction, automotive, and appliance manufacturing, require meticulous handling to maintain their integrity and utility. A straighten and cutting machine ensures that these coils meet rigorous specifications, ultimately facilitating seamless integration into various production lines.

Experience with such machinery reveals its unrivaled precision. In the past, manual handling of steel coils often led to dimensional inaccuracies and material wastage, compromising the quality and efficiency of the end product. However, with the introduction of advanced straighten and cutting machines, manufacturers have witnessed a transformation. Operators now achieve unparalleled accuracy in cutting, leading to optimal material usage and less scrap. This reduction in waste directly translates into cost savings and boosts overall production efficiency.

From a technical standpoint, the expertise behind modern straighten and cutting machines is a testament to engineering excellence. Equipped with sophisticated computer numerical control (CNC) systems, these machines seamlessly automate the flattening and cutting process. This not only minimizes human error but also enhances the safety of operations, a critical consideration in factories where large steel coils are unwieldy and potentially hazardous.

Moreover, these machines are capable of handling coils of varying dimensions and properties, as they are equipped with adjustable settings to accommodate different steel grades and thicknesses. This versatility ensures that manufacturers can maintain consistent quality across different batches, catering to the evolving demands of their clients with ease and precision.

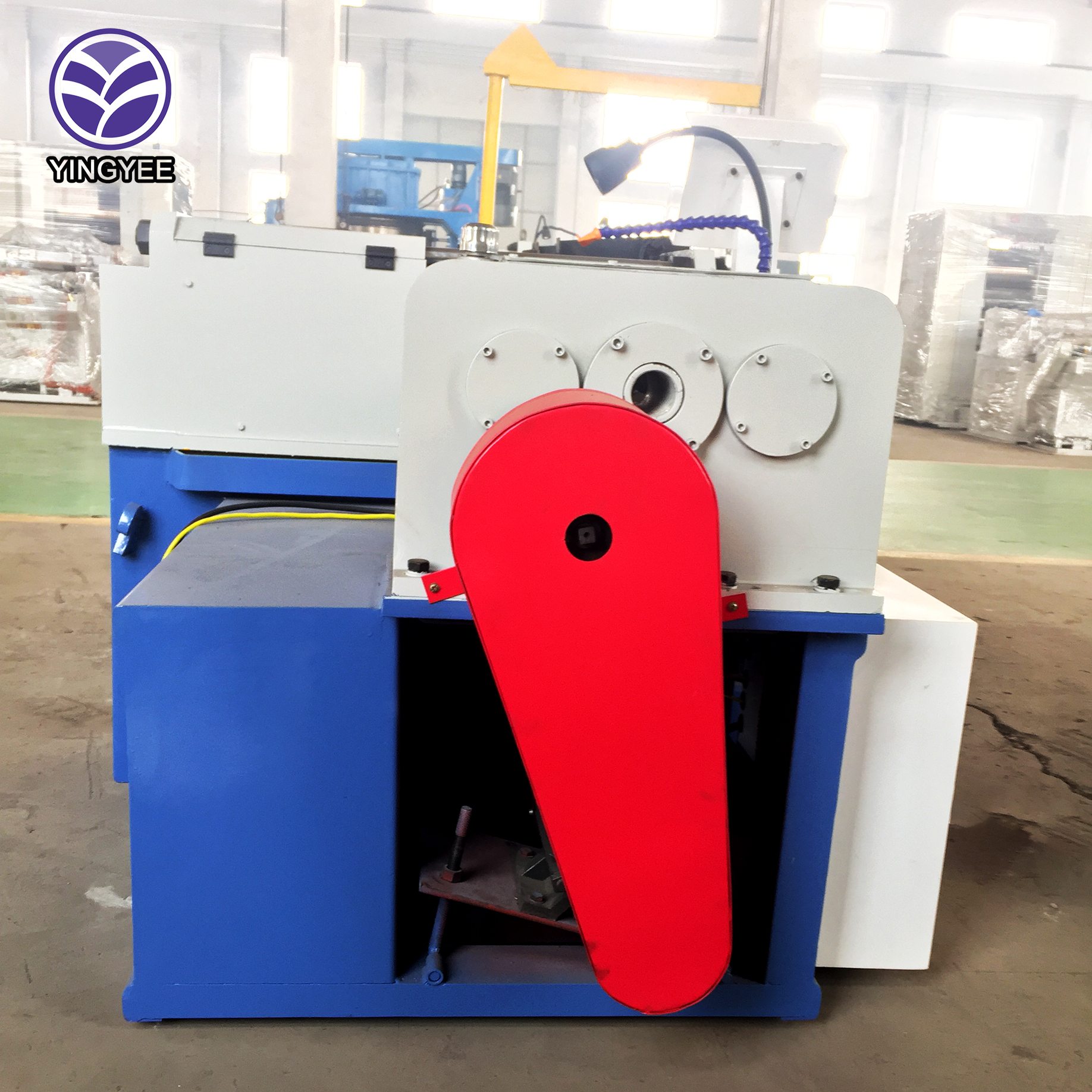

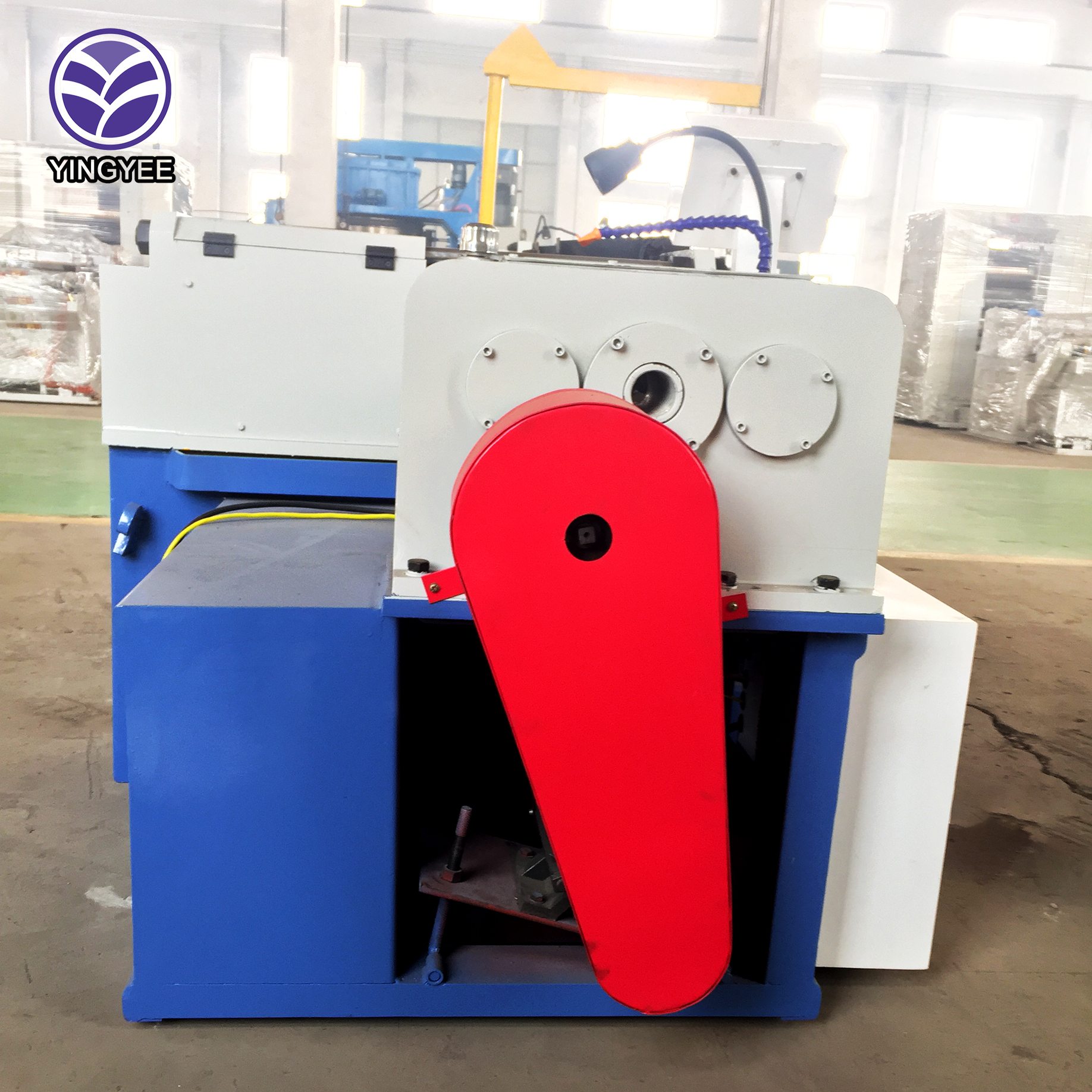

straighten and cutting machine for steel coil

The authoritativeness of modern straighten and cutting machines is further underscored by their integration with smart technologies. With the advent of Industry 4.0, these machines are now connected to centralized systems, allowing for real-time monitoring and data analytics. This connectivity empowers factory managers with insights into performance metrics, enabling predictive maintenance and minimizing downtime. Consequently, this foresight enhances productivity and ensures that production targets are consistently met.

Trustworthiness is paramount in industrial operations, where equipment reliability is non-negotiable.

The latest straighten and cutting machines are manufactured adhering to the highest industry standards. Each unit undergoes rigorous quality checks and certifications, ensuring durability and longevity. Manufacturers also offer comprehensive support services, training operators in the best practices of machine handling and maintenance, further solidifying their reliability in the eyes of clients.

Industrial case studies bolster the credibility and transformational impact of straighten and cutting machines. For instance, manufacturers who have incorporated these machines into their production lines often report a 20-30% increase in throughput within the first few months of operation. Additionally, by reducing error rates, these machines help significantly lower return and rejection rates, enhancing customer satisfaction and strengthening supplier relationships.

In conclusion, the incorporation of straighten and cutting machines for steel coil processing is more than a mere trend—it is a strategic enhancement for any forward-thinking manufacturing enterprise. As the global demand for high-quality steel components continues to rise, those equipped with such advanced machinery will be better positioned to meet and exceed market expectations, solidifying their state-of-the-art status in the industry.