The Advancements in Roofing Sheet Forming Galvanized Steel Machines

In the construction and manufacturing industries, the demand for high-quality roofing materials is ever-increasing. Roofing sheets manufactured from galvanized steel have become a preferred choice due to their durability, resistance to corrosion, and aesthetic appeal. The technology behind roofing sheet forming galvanized steel machines plays a crucial role in meeting these demands efficiently and effectively.

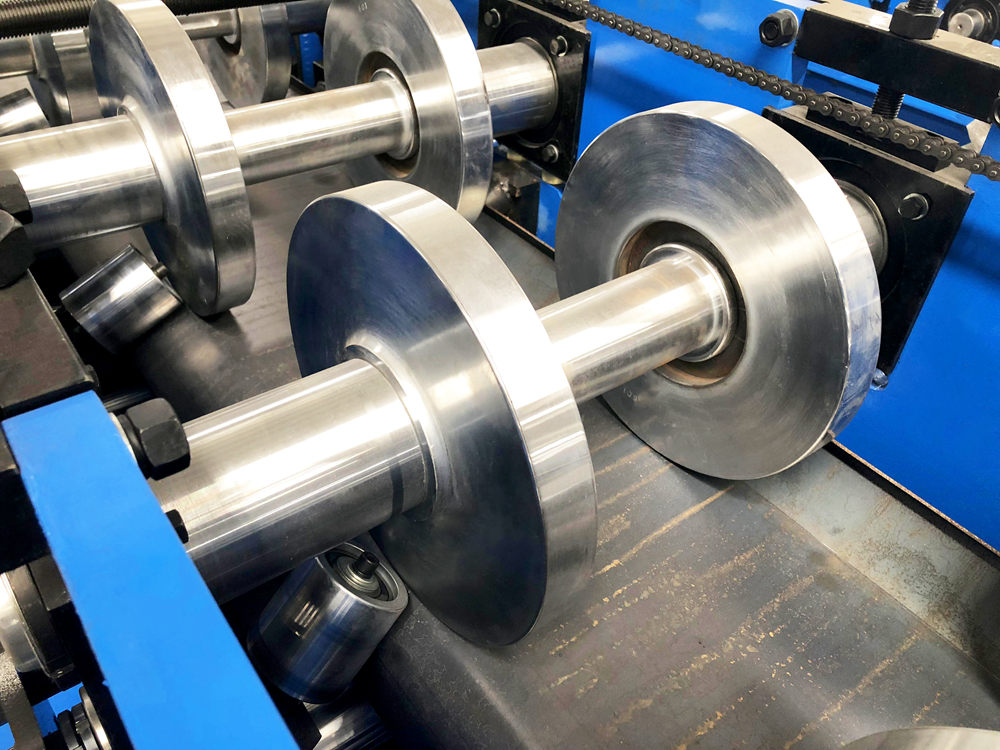

Galvanized steel, a type of steel coated with zinc to prevent rusting, is an ideal material for roofing applications due to its longevity and resistance to harsh environmental conditions. The forming machines designed for roofing sheets utilize advanced technology to ensure that the sheets are produced with precision and uniformity. These machines are capable of transforming flat galvanized steel coils into shaped roofing sheets through a series of processes including cutting, bending, and embossing.

One of the key benefits of using roofing sheet forming machines is their efficiency. Modern machines are designed with high-speed operations in mind, significantly reducing the time required to produce large quantities of roofing sheets. For instance, some machines can produce several meters of roofing sheet every minute, increasing productivity while ensuring high-quality standards are maintained. This efficiency not only enhances production rates but also reduces labor costs, allowing manufacturers to allocate resources more effectively.

Moreover, the automation of roofing sheet forming machines has revolutionized the manufacturing process. With computerized controls, these machines can be programmed to produce various shapes and sizes of roofing sheets, catering to the specific needs of different projects. This flexibility ensures that manufacturers can meet customer demands without the need for extensive retooling, thereby enhancing adaptability in a fast-paced market.

Quality control is another significant advantage of employing advanced roofing sheet forming machines. These machines are equipped with sensors and monitoring systems that continuously check for production quality. This capability minimizes the occurrence of defects, resulting in a consistent product that meets stringent industry standards. As a result, builders and contractors can rely on the roofing sheets produced to maintain their integrity over time, reducing the likelihood of repairs and replacements.

Furthermore, the environmental benefits of using galvanized steel in roofing sheet production cannot be overlooked. Galvanized steel is 100% recyclable, making it a sustainable option for construction materials. The efficiency of modern forming machines reduces waste during the manufacturing process, ensuring that minimal material is discarded. As the world becomes increasingly aware of environmental issues, the shift towards sustainable materials and processes has become imperative in the construction industry.

Training and technical support for operators of roofing sheet forming machines are also vital aspects that contribute to the overall success of the manufacturing process. Investing in the skills development of personnel ensures that they can operate the machines efficiently and troubleshoot any issues that may arise. This investment ultimately leads to higher productivity levels and reduces downtime during production.

In conclusion, roofing sheet forming galvanized steel machines represent a critical advancement in the construction industry. Their efficiency, automation, quality control capabilities, and environmental advantages position them as essential tools for manufacturers. As the demand for high-quality, durable roofing solutions continues to rise, the evolution of these machines will undoubtedly play a pivotal role in shaping the future of roofing applications. By embracing modern technological innovations, manufacturers can ensure they remain competitive in an ever-evolving market, all while contributing to sustainable practices that benefit both the industry and the environment.