Understanding Metal Roofing Roll Forming Machines

In the construction and manufacturing industry, metal roofing has become an increasingly popular choice due to its durability, energy efficiency, and overall cost-effectiveness. One of the vital components in the production of metal roofing is the metal roofing roll forming machine. This advanced piece of equipment is designed to transform flat metal sheets into various roofing profiles through a continuous forming process. In this article, we will explore the features, benefits, and applications of metal roofing roll forming machines.

What is a Metal Roofing Roll Forming Machine?

A metal roofing roll forming machine is an automated device that shapes metal strips into specific roofing profiles by passing them through a series of rollers. These machines are versatile and can produce different types of metal roofing products, including standing seam panels, corrugated sheets, and shingles, among others. The process begins with a coil of sheet metal, typically made of materials like steel or aluminum, which is fed into the machine. As the coil moves through the rollers, it gradually takes on the desired shape, which can then be cut to length for installation.

Key Features

1. Versatility One of the primary advantages of roll forming machines is their ability to produce various profiles from the same machine. By simply changing the roller setup, manufacturers can switch between different designs without needing a completely new machine.

2. Efficiency These machines operate continuously, allowing for high production rates. The automation significantly reduces labor costs and the risk of human error, leading to more consistent product quality.

3. Durability Metal roofing is known for its toughness, and the roll forming machine is built to last, often constructed from high-quality materials that can withstand the rigors of manufacturing processes.

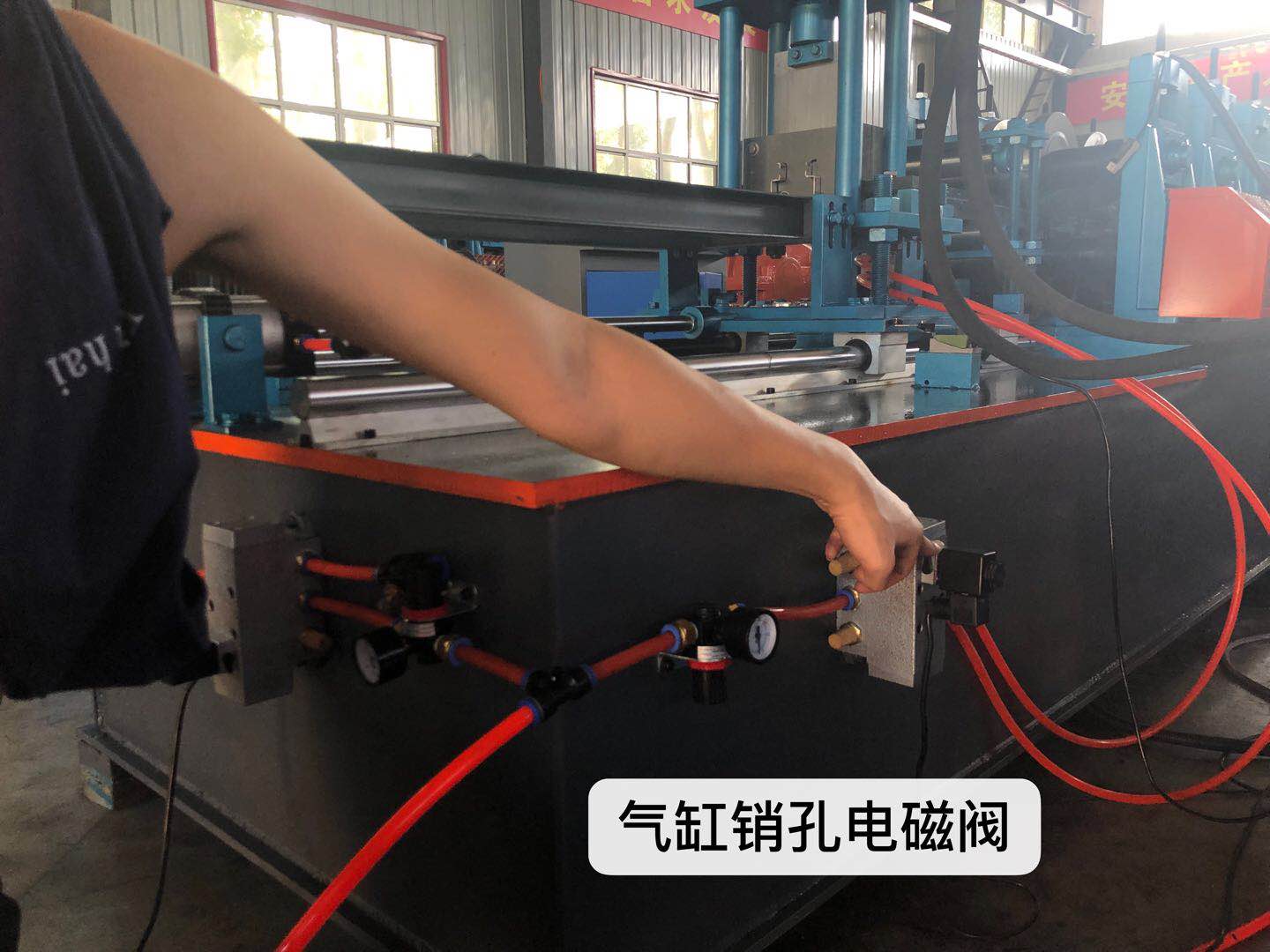

4. Precision Advanced computer controls allow for precise adjustments to the machine, ensuring that each piece of roofing material meets specified dimensions and tolerances. This precision is crucial for proper installation and building integrity.

5. Customization Many roll forming machines offer options for custom designs and profiles, enabling manufacturers to meet specific customer requirements or architectural styles.

Benefits of Using Metal Roofing Roll Forming Machines

1. Cost-Effectiveness The initial investment in a roll forming machine can be offset by the reduction in material waste and labor costs. The continuous production process minimizes off-cuts and ensures that every inch of material is utilized effectively.

2. Quality Assurance The automated nature of roll forming ensures that each roofing product maintains consistent quality, which is vital for both aesthetic and functional purposes.

3. Quick Turnaround With the capability to produce large quantities in a short period, businesses can respond to market demands swiftly, ensuring timely deliveries and customer satisfaction.

4. Sustainability Metal roofing is often recyclable, and the roll forming process generates minimal waste. This environmentally friendly aspect appeals to many modern consumers who prioritize sustainability in their purchasing decisions.

Applications

The applications of metal roofing roll forming machines are vast. They are used in residential, commercial, and industrial construction projects. Popular uses include

- Residential Roofing Homeowners are increasingly choosing metal roofs for their homes due to longevity and energy efficiency.

- Commercial Buildings Metal roofing solutions at industrial sites offer substantial protection against the elements, enhancing the life span of the building.

- Agricultural Structures Many barns and agricultural buildings utilize metal roofing for its durability and resistance to harsh weather conditions.

Conclusion

Metal roofing roll forming machines play a crucial role in the roofing industry, providing efficient, precise, and customizable solutions for a variety of applications. As the demand for metal roofing continues to grow, so too does the importance of advanced machinery that can deliver high-quality products at competitive prices. Investing in a modern roll forming machine not only streamlines production processes but also enhances the overall quality of metal roofing products, thereby meeting the evolving needs of the construction market.