The Importance of Metal Roof Sheet Making Machines in Construction

In the ever-evolving world of construction, the demand for durable, sustainable, and efficient materials is on the rise. Among these materials, metal roofing has emerged as a popular choice due to its longevity, strength, and aesthetic appeal. To meet this growing demand, metal roof sheet making machines have become an essential part of the manufacturing process, enabling producers to create high-quality metal roofing sheets with precision and speed.

Understanding Metal Roof Sheet Making Machines

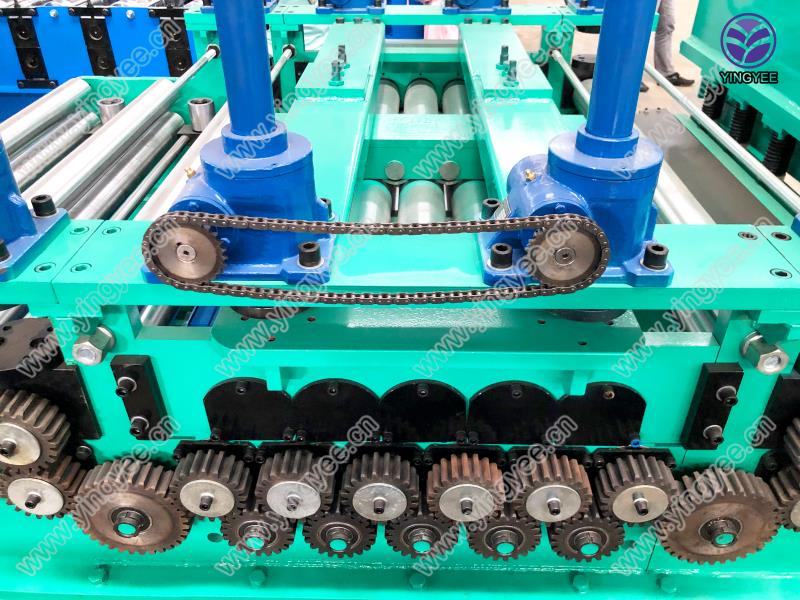

Metal roof sheet making machines are specialized equipment designed to manufacture various types of metal roofing sheets from raw materials. These machines typically use processes such as roll forming, cutting, and shaping to produce sheets that can be customized in terms of size, thickness, and finish. The primary materials used in these machines are steel, aluminum, and copper, which are known for their durability and resistance to environmental factors.

The production process begins with feeding the raw metal coils into the machine. The coils are then processed through a series of rollers that progressively shape the metal into the desired profile. After forming, the sheets are cut to length and can be further treated with coatings to enhance their resistance to corrosion and UV rays. The efficiency of these machines allows manufacturers to produce large quantities of roofing sheets, making them an indispensable asset in the roofing industry.

Advantages of Using Metal Roof Sheet Making Machines

1. Cost-Effectiveness One of the most significant advantages of metal roof sheet making machines is their ability to produce materials at a lower cost. With the high-speed production capabilities, manufacturers can efficiently meet large orders, reducing labor costs and material waste.

2. Customization Modern metal roof sheet making machines offer various customization options. Manufacturers can easily adjust settings to produce sheets of different shapes, sizes, and finishes, catering to the unique needs of clients and ensuring that their products stand out in the market.

3. Durability and Quality The technology used in metal roof sheet making machines ensures that the final products are of high quality. The precision involved in the manufacturing process results in durable roofing sheets capable of withstanding harsh weather conditions, thereby enhancing the longevity of buildings.

4. Environmentally Friendly Metal roofing is one of the most sustainable options available in the construction industry. Metal roof sheet making machines contribute to this sustainability by enabling the use of recycled materials and reducing waste during production. Furthermore, metal roofing reflects heat from the sun, leading to lower energy costs for heating and cooling buildings.

The Future of Metal Roof Sheet Manufacturing

As technology continues to advance, so will the capabilities of metal roof sheet making machines. Innovations in automation and robotics are expected to play a significant role in increasing production efficiency while maintaining high-quality standards. Additionally, the integration of smart technologies such as IoT (Internet of Things) will allow manufacturers to monitor production processes in real-time, leading to improved maintenance and reduced downtime.

Moreover, the growing emphasis on energy-efficient construction practices will further fuel the demand for metal roofing solutions. With more architects and builders recognizing the long-term benefits of metal roofs, the market for metal roof sheet manufacturing is poised for substantial growth.

Conclusion

In conclusion, metal roof sheet making machines are vital components in the construction industry, providing an efficient, cost-effective, and sustainable method for producing high-quality roofing materials. As the demand for metal roofing continues to rise, these machines will remain essential for manufacturers looking to stay competitive in this dynamic market. By investing in advanced metal roof sheet making machines, companies not only enhance their production capabilities but also contribute to a more sustainable future in construction.