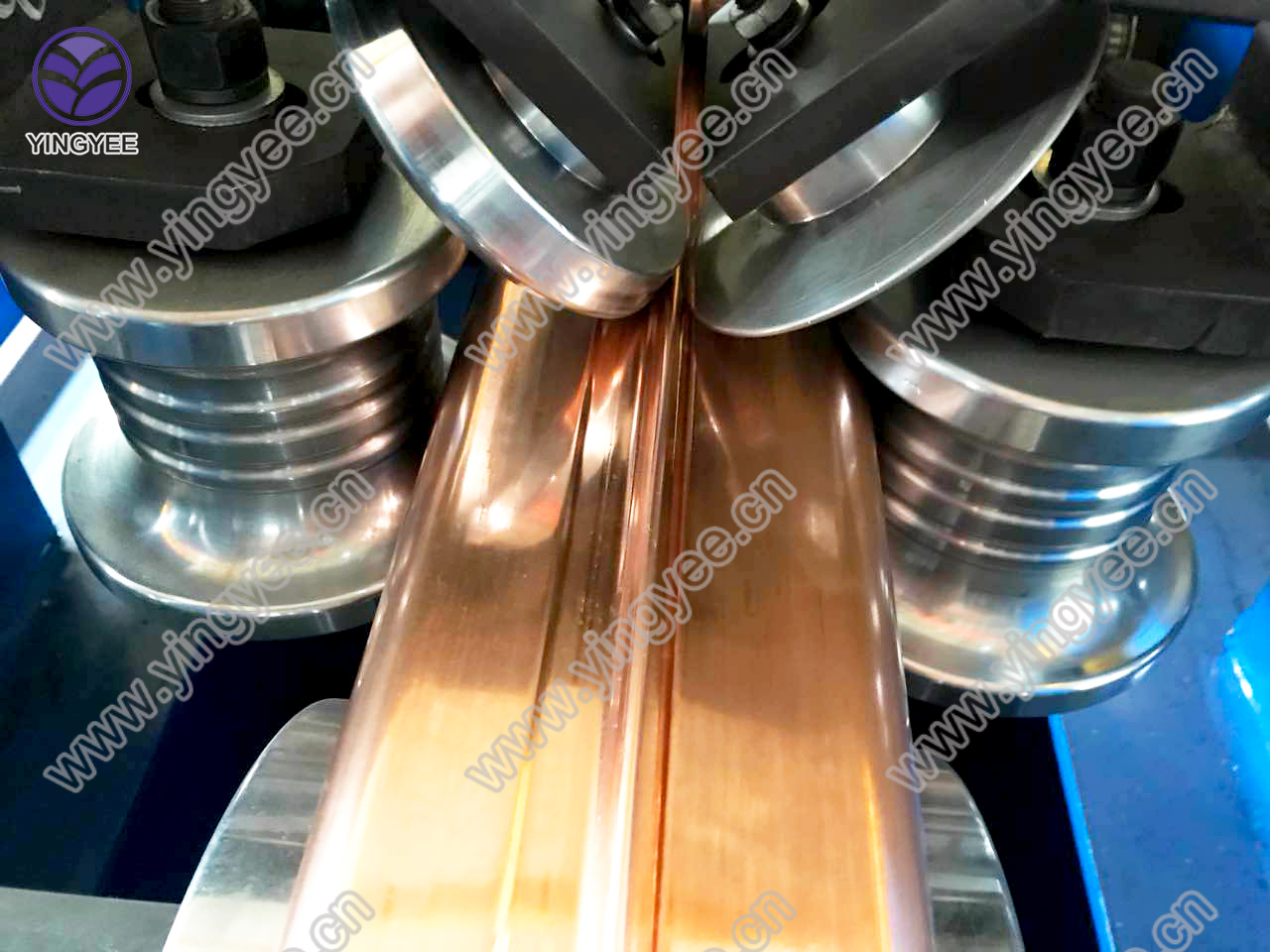

The Importance of Corrugated Deck Cold Bending Machines in Modern ConstructionIn the realm of modern construction, efficiency and precision are paramount. One of the essential tools that has evolved to meet these demands is the corrugated deck cold bending machine. This innovative equipment plays a significant role in shaping the steel sheets used in constructing building decks, roofs, and various structural components, providing both strength and aesthetic appeal to contemporary structures.A corrugated deck cold bending machine is specifically designed to process steel sheets into various corrugated forms, which are known for their enhanced structural integrity and lightweight properties. These machines utilize a cold bending process, which means that the metal is shaped at room temperature, preserving its strength and eliminating the need for additional heating. This process not only streamlines production but also reduces the risk of thermal distortion and metal fatigue.One of the primary benefits of utilizing a corrugated deck cold bending machine is the material efficiency it offers. By enabling precise bending, these machines minimize waste, allowing construction companies to make the most of their resources. Every cut and bend is executed with accuracy, ensuring that less material is discarded during the manufacturing process. This efficiency translates into cost savings for builders, making it an economically sound choice for large-scale projects.Moreover, the corrugated design that these machines produce is not merely functional but also enhances the aesthetic value of construction projects. The unique wave-like patterns of corrugated sheets can add a modern touch to buildings, making them visually appealing while providing essential structural support. Many architects and builders are now turning to corrugated panels for both interior and exterior applications, recognizing their versatility and the degree to which they can elevate design schemes.Another significant advantage of using cold bending machines is the speed of production. Automated systems are capable of processing large volumes of material in a relatively short time, thereby accelerating the overall construction timeline. This rapid production capability allows construction teams to adhere to tight schedules and meet project deadlines without compromising on quality. As the construction industry continues to face labor shortages, the efficiency gained from using these machines becomes increasingly vital.Furthermore, cold bending technology supports sustainability in construction. By optimizing material usage and reducing waste, builders contribute to environmentally friendly practices. As governments and organizations worldwide prioritize sustainability, equipment that supports these goals will become even more integral to the industry.In conclusion, corrugated deck cold bending machines are an indispensable asset in modern construction. Their ability to produce strong, aesthetically pleasing materials quickly and efficiently addresses the needs of today’s building projects. As the industry evolves, the reliance on innovative machinery like the corrugated deck cold bending machine will continue to grow, paving the way for more sustainable and cost-effective construction practices. This advancement not only enhances structural integrity but also reflects the changing landscape of design and construction in the 21st century.

The Importance of Corrugated Deck Cold Bending Machines in Modern ConstructionIn the realm of modern construction, efficiency and precision are paramount. One of the essential tools that has evolved to meet these demands is the corrugated deck cold bending machine. This innovative equipment plays a significant role in shaping the steel sheets used in constructing building decks, roofs, and various structural components, providing both strength and aesthetic appeal to contemporary structures.A corrugated deck cold bending machine is specifically designed to process steel sheets into various corrugated forms, which are known for their enhanced structural integrity and lightweight properties. These machines utilize a cold bending process, which means that the metal is shaped at room temperature, preserving its strength and eliminating the need for additional heating. This process not only streamlines production but also reduces the risk of thermal distortion and metal fatigue.One of the primary benefits of utilizing a corrugated deck cold bending machine is the material efficiency it offers. By enabling precise bending, these machines minimize waste, allowing construction companies to make the most of their resources. Every cut and bend is executed with accuracy, ensuring that less material is discarded during the manufacturing process. This efficiency translates into cost savings for builders, making it an economically sound choice for large-scale projects.Moreover, the corrugated design that these machines produce is not merely functional but also enhances the aesthetic value of construction projects. The unique wave-like patterns of corrugated sheets can add a modern touch to buildings, making them visually appealing while providing essential structural support. Many architects and builders are now turning to corrugated panels for both interior and exterior applications, recognizing their versatility and the degree to which they can elevate design schemes.Another significant advantage of using cold bending machines is the speed of production. Automated systems are capable of processing large volumes of material in a relatively short time, thereby accelerating the overall construction timeline. This rapid production capability allows construction teams to adhere to tight schedules and meet project deadlines without compromising on quality. As the construction industry continues to face labor shortages, the efficiency gained from using these machines becomes increasingly vital.Furthermore, cold bending technology supports sustainability in construction. By optimizing material usage and reducing waste, builders contribute to environmentally friendly practices. As governments and organizations worldwide prioritize sustainability, equipment that supports these goals will become even more integral to the industry.In conclusion, corrugated deck cold bending machines are an indispensable asset in modern construction. Their ability to produce strong, aesthetically pleasing materials quickly and efficiently addresses the needs of today’s building projects. As the industry evolves, the reliance on innovative machinery like the corrugated deck cold bending machine will continue to grow, paving the way for more sustainable and cost-effective construction practices. This advancement not only enhances structural integrity but also reflects the changing landscape of design and construction in the 21st century.