The Production Line of Color Stone Coated Roof Tiles

Color stone coated roof tiles have gained immense popularity in recent years due to their aesthetic appeal, durability, and energy efficiency

. The production line of these roof tiles involves a series of intricate processes that ensure the final product meets the highest standards of quality and performance.The production begins with selecting high-quality raw materials. The core material for color stone coated roof tiles is typically made from a lightweight metal, such as aluminum or galvanized steel. These metals are chosen for their strength and resistance to corrosion. The base material is then shaped into tiles of varying sizes and styles, catering to different architectural needs and preferences.

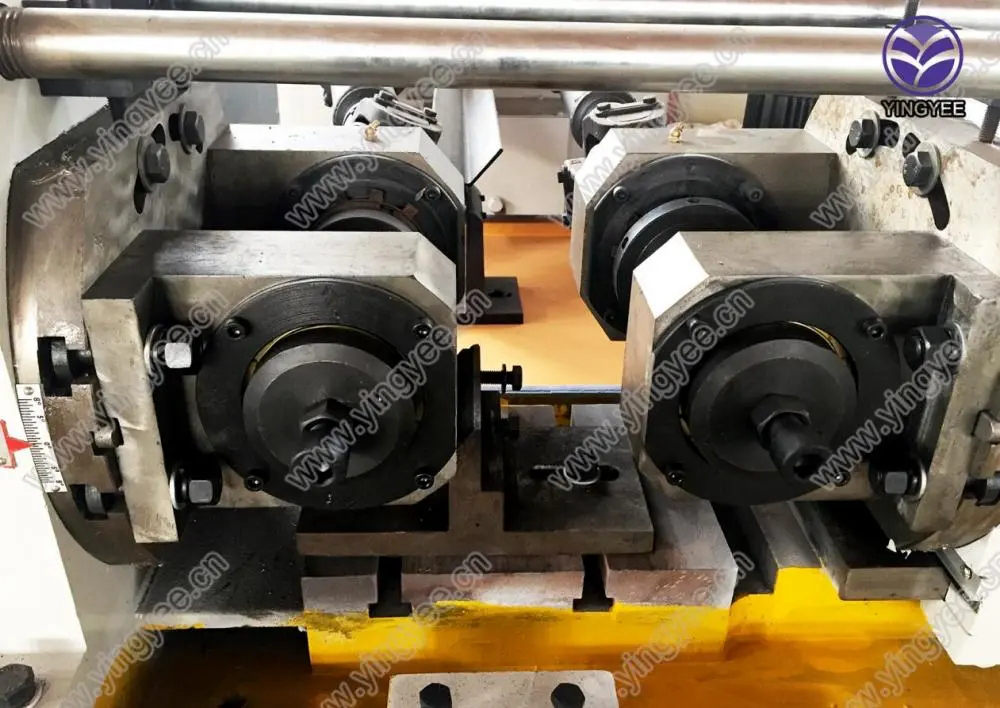

Once the metal tiles are formed, the next crucial step is the application of a protective coating. This coating serves multiple purposes it enhances the tile's durability, adds insulation properties, and provides a base for the stone chips. The coating process often involves applying a layer of acrylic resin or a similar polymer, which bonds the stone chips to the tile effectively.

After the coating is applied, the tiles move to the stone chip application station. Here, natural stone chips, available in various colors, are evenly distributed over the surface of the coated tiles. The choice of stone colors is essential, as it determines the aesthetic of the finished product. The stone chips not only contribute to the visual appeal of the tiles but also offer additional protection from UV radiation and weather elements. Once the stone chips are applied, they are pressed into the coating to ensure a strong bond.

Next in the production line is the curing process, where the tiles are subjected to controlled heat and moisture conditions. This step allows the acrylic resin to fully cure, providing increased strength and resilience to the tiles. The curing process is crucial in ensuring that the coatings adhere correctly and that the tiles can withstand harsh weather conditions over time.

Quality control is integrated throughout the production line. Each batch of tiles undergoes rigorous testing to ensure they meet industry standards for performance, durability, and finish. Tests may include evaluating the adhesion of the stone chips, examining resistance to corrosion, and assessing the overall structural integrity of the tiles.

After passing quality inspections, the finished color stone coated roof tiles are packaged for distribution. They are designed for easy installation, and manufacturers often provide detailed guidelines to aid contractors in the roofing process.

In conclusion, the production line of color stone coated roof tiles is a sophisticated blend of technology and craftsmanship. With a focus on quality materials, innovative processes, and rigorous testing, the industry continues to evolve, offering consumers an attractive and durable roofing solution that can withstand the test of time while enhancing the visual appeal of structures. As the demand for sustainable roofing options grows, these tiles are likely to play a significant role in the future of construction.