The Automatic Solar Bracket Making Line Revolutionizing Solar Energy Solutions

In recent years, the push for renewable energy has gained unprecedented momentum, driven by the urgent need to address climate change and reduce reliance on fossil fuels. Among the various renewable energy sources, solar power has emerged as one of the most promising alternatives. As the demand for solar energy continues to rise, the efficiency of solar panel installation and the supporting infrastructure becomes increasingly crucial. This is where the automatic solar bracket making line plays a significant role in revolutionizing the industry.

The Importance of Solar Brackets

Solar brackets are essential components in the installation of solar panels, providing the necessary support and ensuring their durability and functionality. They are designed to withstand various weather conditions, including heavy winds, snow loads, and extreme temperatures. A well-constructed bracket can significantly enhance the performance and lifespan of solar panels. Therefore, the design and manufacturing of these brackets must prioritize quality, efficiency, and cost-effectiveness.

Advancements in Manufacturing Technology

The automatic solar bracket making line is a state-of-the-art manufacturing system that utilizes advanced technology to produce solar brackets efficiently. This fully automated production line streamlines the entire manufacturing process, from raw material handling to the final assembly of brackets. Traditional manufacturing methods often involve labor-intensive processes that can lead to inconsistencies in quality, higher production costs, and longer lead times. In contrast, an automatic production line eliminates these inefficiencies, enabling manufacturers to meet the increasing demand for solar brackets with precision and speed.

Key Features of an Automatic Solar Bracket Making Line

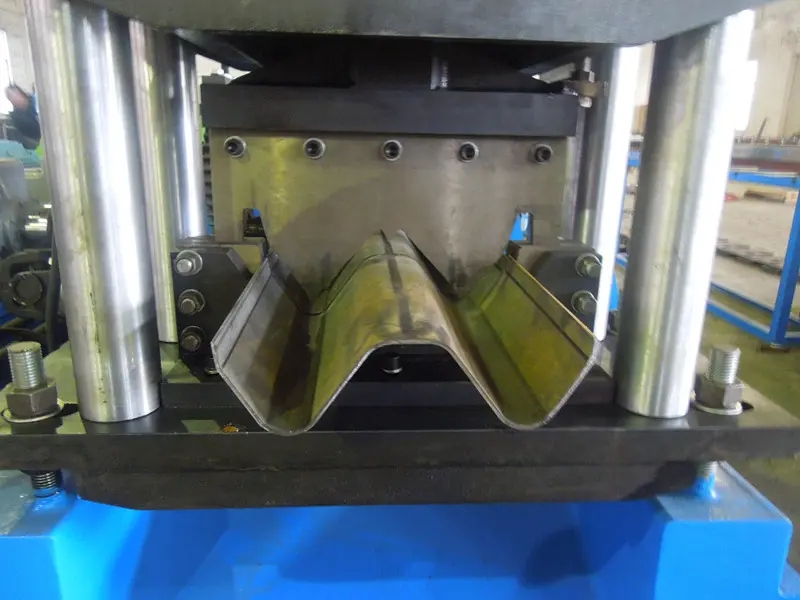

1. Robotic Automation The integration of robotics in the manufacturing process allows for high-speed production with minimal human intervention. Robotic arms can handle various tasks such as cutting, bending, and welding, ensuring a high degree of accuracy and reducing the risk of errors.

2. Smart Technology Many modern production lines are equipped with intelligent software that monitors the manufacturing process in real-time. This technology enables manufacturers to track performance metrics, identify bottlenecks, and implement adjustments to enhance productivity.

3. Modular Design Automatic solar bracket making lines can be designed with modular components, allowing manufacturers to customize the setup based on specific production requirements. This adaptability means that companies can scale their operations efficiently as demand increases.

4. Quality Control Systems Advanced quality control systems are integrated into the production line to ensure that every bracket meets the required specifications. Automated inspections and testing processes significantly reduce the chances of defective products reaching the market.

Environmental Benefits

The shift towards automated manufacturing of solar brackets aligns with the broader goals of sustainable development. By enhancing production efficiency, manufacturers can reduce waste and energy consumption during the manufacturing process. Additionally, as solar energy systems become more accessible and affordable due to these advancements, more individuals and businesses are likely to adopt solar power, further contributing to the reduction of carbon emissions.

Conclusion

The automatic solar bracket making line represents a significant leap forward in the solar energy industry. By improving the efficiency and accuracy of solar bracket production, this technology not only meets the growing demand for solar energy solutions but also promotes sustainable manufacturing practices. As the world continues to transition to cleaner energy sources, innovations like these will play a pivotal role in shaping a more sustainable future. As we look ahead, the integration of automation in manufacturing processes will become increasingly essential for driving down costs, improving product quality, and ultimately supporting the global shift towards renewable energy. The future of solar energy is bright, and automatic solar bracket making lines are set to lead the way.