Understanding the Upright Rack Roll Forming Machine

In the realm of industrial manufacturing, efficiency and precision are paramount. One of the key technologies that exemplify these attributes is the upright rack roll forming machine. This advanced piece of equipment is engineered to produce high-quality frames and racks that are essential for various applications, particularly in warehouse and storage systems.

What is a Roll Forming Machine?

A roll forming machine is a type of industrial machinery used to shape metal into specific profiles. The process involves feeding a continuous strip of metal through a series of rollers that progressively bend and shape it into the desired cross-section. This method is exceptionally efficient for producing long lengths of metal shapes, which can later be cut down to specific sizes.

The Role of the Upright Rack Roll Forming Machine

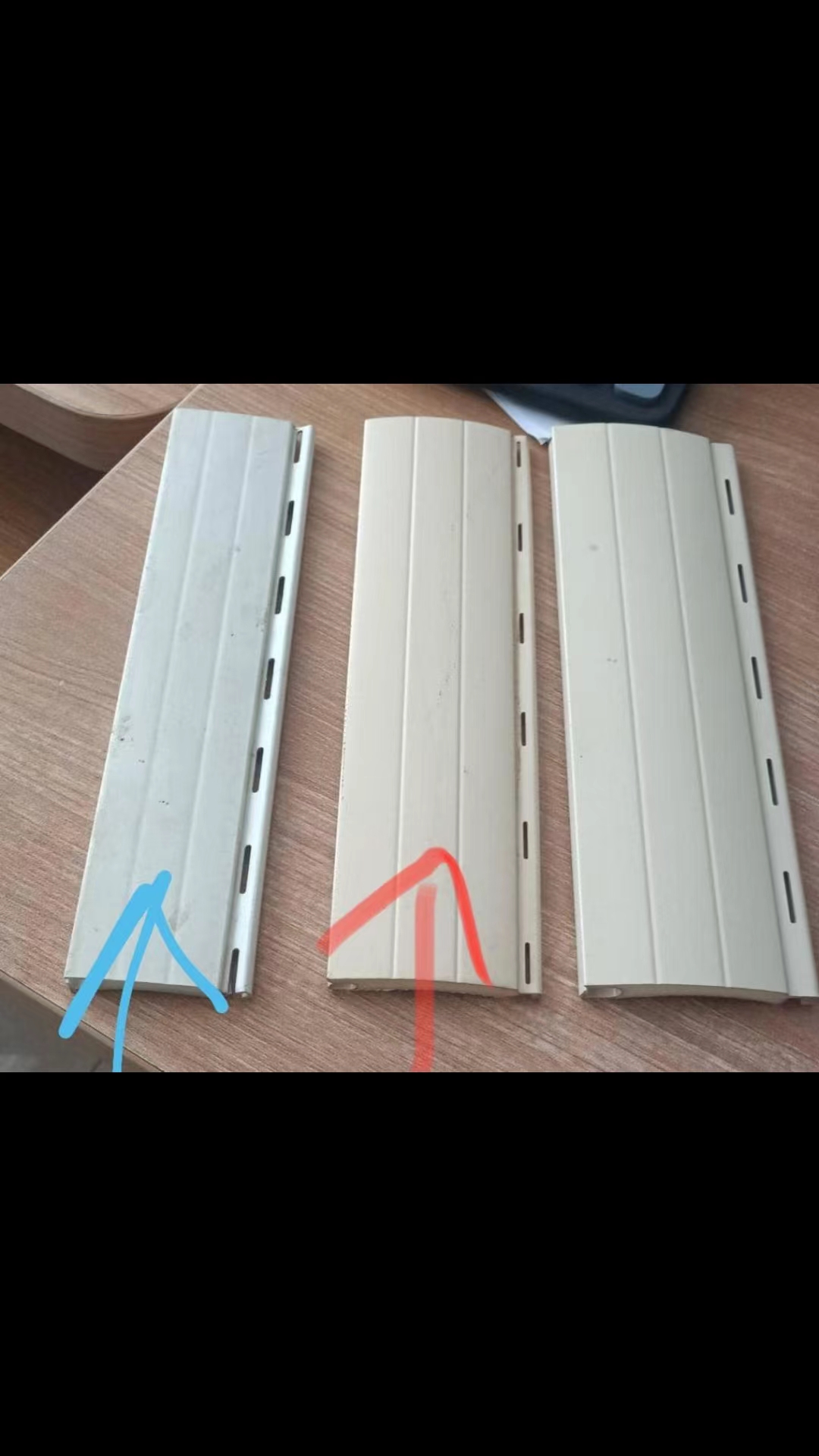

The upright rack roll forming machine is specialized for producing upright frames commonly used in pallet racking systems. These uprights are crucial components that support horizontal beams and ultimately hold the weight of the stored goods. The machine is designed to create durable, robust frames that can withstand heavy loads and challenging warehouse conditions.

This specific type of machinery can handle various materials, including steel and aluminum, allowing manufacturers to adapt to different project requirements. By utilizing high-quality raw materials, the finished products exhibit superior strength and durability, essential for ensuring safety and reliability in storage applications.

Key Features of Upright Rack Roll Forming Machines

1. Precision Engineering One of the standout features of these machines is their precision. The rollers are designed to ensure that each bend and cut is executed flawlessly, resulting in a consistent product that meets strict tolerances.

2. High Production Efficiency These machines are capable of producing large quantities of uprights within a short timeframe. This efficiency significantly reduces production costs and enhances the output for manufacturers.

3. Versatility Modern upright rack roll forming machines can be programmed for different specifications, allowing manufacturers to switch between various designs with minimal downtime.

4. Automated Systems Most advanced machines feature automation, including automatic feeding and cutting systems. This automation not only enhances efficiency but also reduces the risk of human error during production.

5. Quality Control Built-in quality control systems in these machines ensure that every piece produced meets predefined quality standards. This feature is critical in maintaining the trust of customers and adhering to safety regulations.

Applications of Upright Rack Systems

Upright racks produced by roll forming machines are widely utilized in various industries, including

- Warehousing Providing essential storage solutions for goods and products. - Retail Used in stockrooms and display areas. - Manufacturing Plants Supporting materials and finished products during the production process. - Logistics Facilitating the efficient movement and storage of goods.

The advantages of using upright racks include optimized space utilization, improved accessibility to products, and increased efficiency in inventory management.

Conclusion

In summary, the upright rack roll forming machine is a pivotal technology in the manufacturing sector. Its ability to produce high-quality, durable rack systems efficiently makes it an invaluable asset for industries reliant on effective storage solutions. With ongoing advancements in roll forming technology, manufacturers can expect even greater efficiency, precision, and versatility in their production processes, ultimately meeting the ever-evolving demands of the market. As the need for organized and efficient storage systems continues to rise, the significance of upright rack roll forming machines will only increase, solidifying their place as a critical component in modern manufacturing strategies.