Exploring T Ceiling Keel Forming Machine Suppliers

In today’s construction and interior design industries, the demand for quality and precision in manufacturing components has never been higher. One notable area of growth is the production of ceiling systems, which often requires intricate components like T ceiling keels. These keels play a critical role in providing support and stability for ceiling tiles and panels, ensuring aesthetic appeal and functional integrity. As such, the role of T ceiling keel forming machine suppliers becomes paramount in meeting this growing demand.

What is a T Ceiling Keel Forming Machine?

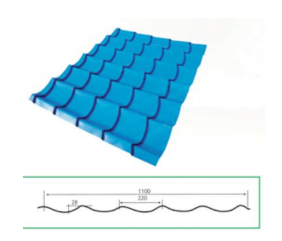

A T ceiling keel forming machine is a specialized piece of equipment used to manufacture T-shaped profiles for suspended ceiling systems. These machines typically take steel coils and transform them into precision-engineered keels through a series of processes including forming, cutting, and punching. The end product must meet stringent industry standards for strength, durability, and finish. This complex manufacturing process requires advanced technology and skilled input, making the choice of supplier crucial for contractors, builders, and manufacturers alike.

The Importance of Quality Suppliers

Choosing a reliable T ceiling keel forming machine supplier is fundamental to the success of any construction project. High-quality machines can significantly enhance production efficiency, reduce waste, and improve the overall quality of the end products. Conversely, subpar machines may lead to increased downtime, inferior keels, and ultimately, dissatisfied clients.

Quality suppliers typically offer

1. Advanced Technology The latest forming machines utilize cutting-edge technology, delivering precision and speed. Suppliers who invest in R&D can ensure their machines remain competitive. 2. Customization The ability to customize machines based on the specific needs of clients can be a significant advantage. Custom solutions can include the machine size, speed, and features integrated into the manufacturing process. 3. Technical Support and Maintenance Quality suppliers provide ongoing support, including installation, maintenance, and training. This helps manufacturers minimize downtime and ensures that operatives are skilled in using the machines efficiently.

4. Cost-Effectiveness While it can be tempting to opt for the cheapest supplier, it is often more prudent to prioritize quality. Investments in robust machinery often pay off in terms of production efficiency and reduced operating costs over time.

Key Players in the Market

The market for T ceiling keel forming machines features numerous suppliers, each contributing unique capabilities and offerings. Some well-established companies have developed a reputation for excellence through years of consistent performance and innovation. These suppliers typically leverage a robust network of partnerships and have access to high-quality materials.

Moreover, many suppliers now emphasize sustainable practices in their manufacturing processes. As the industry becomes increasingly aware of its environmental footprint, suppliers who adhere to sustainability standards and utilize energy-efficient technologies stand to gain a competitive edge.

Export and Globalization

With the globalization of the construction industry, T ceiling keel forming machine suppliers are also expanding their reach internationally. This trend is driven by the rising demand for standardized construction components across various regions. Suppliers who can navigate international shipping and regulations are well-positioned to serve a global market.

In addition, the advent of online platforms has facilitated easier access for buyers to connect with suppliers around the world. This means buyers can compare offerings, specifications, and prices quickly, leading to more informed purchasing decisions.

Future Trends

As the manufacturing landscape evolves, several trends are influencing the market for T ceiling keel forming machines. Automation and AI are becoming increasingly integrated into manufacturing processes, offering opportunities for enhanced efficiency and precision. Additionally, the industry is moving towards more sustainable practices, with an emphasis on reducing waste and energy consumption during production.

Conclusion

In summary, T ceiling keel forming machines are crucial components in the construction and design industry, and choosing the right supplier can significantly impact project outcomes. By focusing on quality, customization, and technological advancement, suppliers can help meet the demands of a rapidly evolving market. As globalization continues to expand opportunities, a forward-thinking approach will be key to success, ensuring that ceiling systems not only meet industry standards but exceed customer expectations. Whether you are a contractor in need of reliable materials or a manufacturer looking to optimize production, understanding the role and capabilities of T ceiling keel forming machine suppliers is essential for achieving your goals.