The Evolution of Stud and Track Making Machines

In the realm of industrial manufacturing, the production of metal fasteners like studs and tracks is an integral aspect of various sectors, including construction, automotive, and general engineering. The machines designed for creating these essential components have evolved tremendously since their inception, reflecting advancements in technology, efficiency, and precision.

Historical Background

The process of creating studs and tracks dates back to the early days of metalworking. Traditional methods such as forging and hand crafting were labor-intensive and time-consuming. The need for consistent quality and mass production led to the development of specialized machinery. The first stud and track making machines emerged during the industrial revolution, incorporating steam power and mechanization to enhance production speed and reduce human error.

Modern Stud and Track Making Machines

Today, stud and track making machines are sophisticated pieces of equipment that utilize computer numerical control (CNC) technology. CNC machines have revolutionized manufacturing by allowing for the precise control of tools and machinery through programmable commands. This capability means that manufacturers can produce a wide variety of designs and specifications with extreme accuracy, which is vital in industries where dimensions and tolerances are critical.

Modern machines are capable of producing studs and tracks from various materials, including steel, aluminum, and even plastic composites. The choice of materials depends on the application requirements; for instance, automotive applications often require lightweight but strong materials to improve fuel efficiency without compromising structural integrity.

Key Features

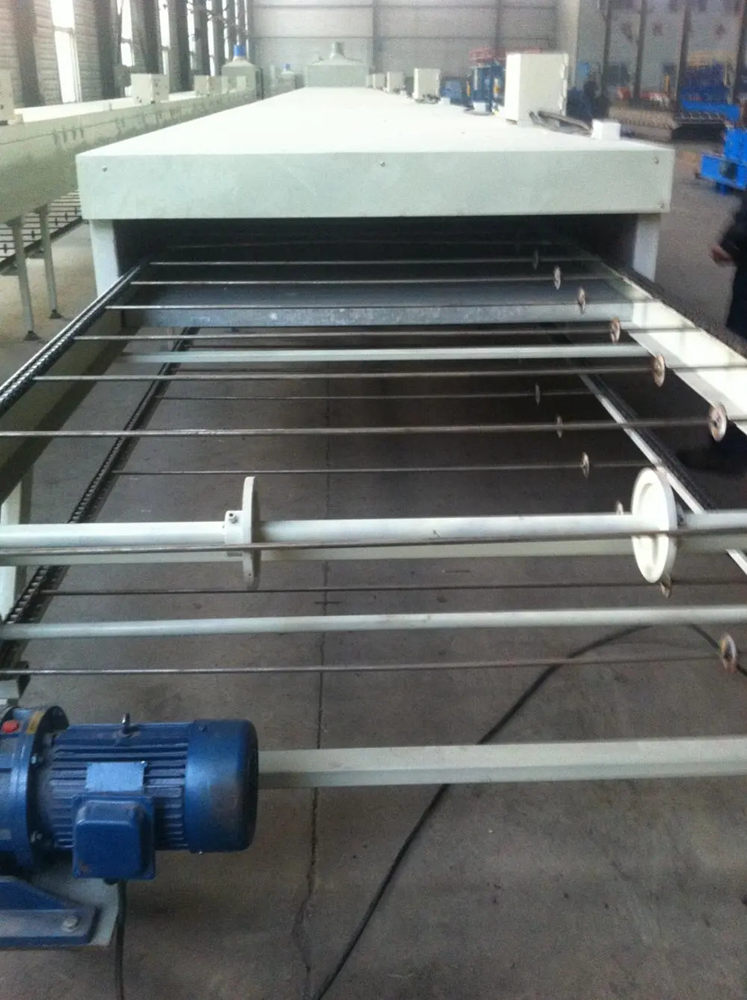

1. Automation Today’s machines often incorporate automation features such as robotic arms and automated feeding systems. This not only enhances production speed but also improves safety by minimizing human involvement in hazardous processes.

2. Precision Engineering The integration of laser cutting and CNC machining allows for intricate designs that were once impossible to achieve with traditional methods. This precision is crucial for applications where fit and strength are paramount.

3. Flexibility Modern machines can easily switch between different types of studs and tracks without necessitating extensive downtime for reconfiguration. This versatility is particularly beneficial for manufacturers that produce small batches of customized parts.

4. Quality Control Advanced machines are equipped with sensors and monitoring systems that perform real-time quality checks during production. This capability significantly reduces the risk of defects, ensuring that all produced pieces meet industry standards.

Environmental Considerations

As with all manufacturing processes, the production of studs and tracks has environmental implications. Modern machines are designed with sustainability in mind, incorporating energy-efficient technologies and minimizing waste. Techniques such as remanufacturing and recycling of scrap materials contribute to a more sustainable production cycle. Manufacturers are increasingly adopting practices that align with global environmental standards, engaging in efforts to reduce their carbon footprint.

Future Trends

The future of stud and track making machines looks promising, with ongoing innovations poised to further enhance their capabilities. The incorporation of artificial intelligence (AI) and machine learning is expected to optimize production processes and predictive maintenance, reducing downtime and improving operational efficiency. Additionally, advancements in materials science may lead to the development of new alloys that provide better performance characteristics, setting the stage for a new generation of fasteners.

Conclusion

In conclusion, the machines that produce studs and tracks have undergone significant transformation over the years. From their humble beginnings in manual processing to the advanced, automated systems of today, these machines are crucial to supporting a wide array of industries. As technology continues to advance, we can anticipate even more impressive innovations that will not only enhance productivity and quality but also address the growing demand for sustainable manufacturing practices. Thus, the evolution of stud and track making machines is a reflection of broader trends in manufacturing, underscoring our ongoing quest for efficiency, quality, and environmental responsibility.