The Stud and Track Forming Machine Innovations in Metal Fabrication

In the realm of metal fabrication, efficiency and precision are paramount. One of the most significant advancements in this field is the stud and track forming machine. This innovative piece of equipment has revolutionized the way metal studs and tracks are produced, significantly enhancing productivity and accuracy in construction and manufacturing industries.

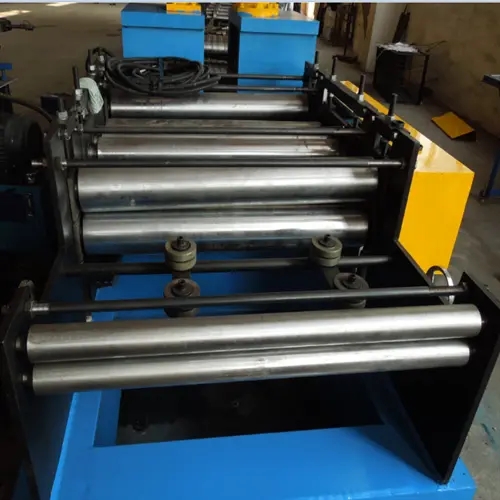

The stud and track forming machine operates on a simple yet effective principle it transforms flat metal sheets into complex forms through a series of controlled processes. The machine is designed to create metal studs, which are essential in both residential and commercial construction for framing walls, ceilings, and other structures. Tracks, on the other hand, serve as the base that supports these studs, forming a stable framework for various applications.

One of the key benefits of using a stud and track forming machine is its ability to produce materials at a rapid pace. Traditional methods of metal fabrication often involve time-consuming manual processes, leading to higher labor costs and extended project timelines. In contrast, automated forming machines can generate large quantities of studs and tracks within a fraction of the time, allowing contractors to complete projects more efficiently.

Moreover, the precision of these machines ensures that each stud and track produced meets strict specifications. This accuracy minimizes the risk of material waste and reduces the likelihood of errors that could compromise the structural integrity of a building. With adjustable settings and programmatic controls, operators can easily modify the dimensions and shapes of the products, catering to specific project requirements without the need for extensive retooling.

Another significant advantage of stud and track forming machines is their versatility. Beyond traditional metal studs and tracks, these machines can also be adapted to produce various custom shapes and profiles. This flexibility makes them invaluable in industries such as automotive, aerospace, and even furniture manufacturing, where unique designs are often necessary.

In addition to their operational benefits, stud and track forming machines contribute to sustainability within the industry. By optimizing material usage and reducing waste, they align with the growing focus on environmentally responsible manufacturing practices. As construction methods continue to evolve, the demand for efficient production techniques will only increase, solidifying the place of stud and track forming machines as essential tools in modern fabrication.

In conclusion, the stud and track forming machine represents a significant leap forward in metal fabrication. Its efficiency, precision, versatility, and sustainability attributes make it a vital asset in the construction and manufacturing sectors, paving the way for a more streamlined and effective approach to creating essential building components. As technology continues to advance, the future of metal fabrication looks brighter than ever.