The Advancements in Stud and Track Drywall Forming Machines

In recent years, the construction industry has witnessed significant advancements in technology, particularly in the manufacturing of drywall systems. One of the most notable innovations is the stud and track drywall forming machine, a piece of equipment designed to streamline the production process of drywall components. This article explores the features, benefits, and future of these machines in the construction sector.

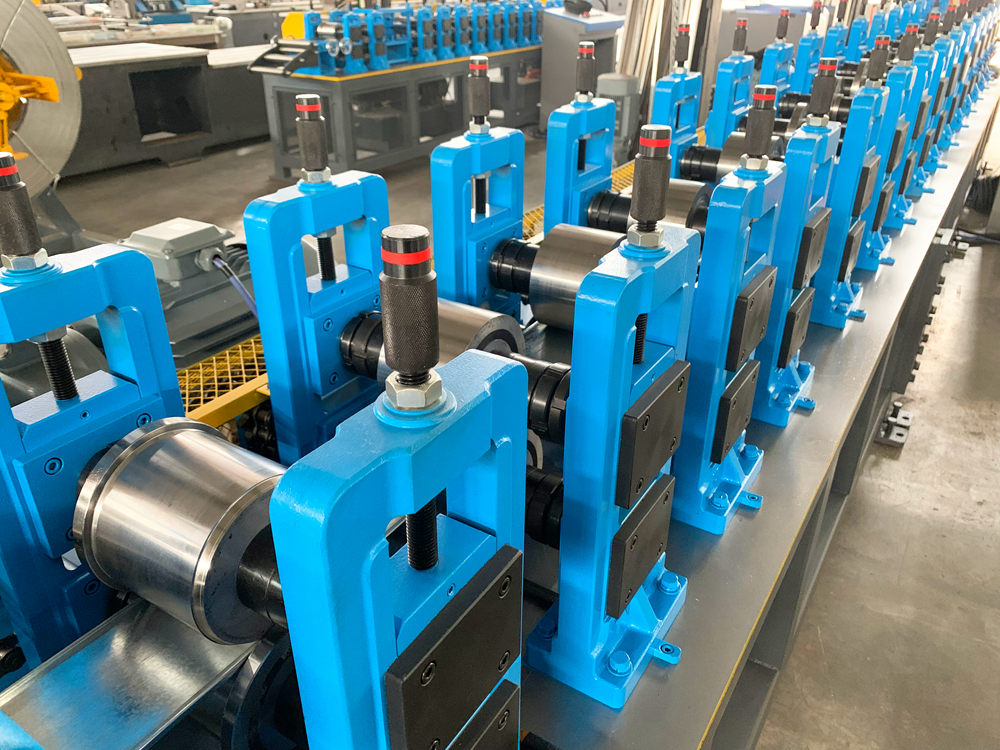

A stud and track drywall forming machine is engineered to create metal studs and tracks used for drywall installation. These machines automate the process of cutting, forming, and punching metal sheets into precise shapes and sizes, which are crucial for residential and commercial building frameworks. The automation not only increases efficiency but also significantly reduces labor costs and time.

One of the primary features of these machines is their ability to produce a variety of stud and track profiles. Manufacturers can customize the dimensions and configurations according to specific project requirements. This versatility is paramount in adapting to the diverse demands of construction, whether for standard wall assemblies or specialized applications like curved walls.

The incorporation of advanced technology has revolutionized the way these machines operate. Many modern stud and track drywall forming machines are equipped with Computer Numerical Control (CNC) systems. These systems allow for greater accuracy and repeatability, ensuring that each component produced meets the stringent standards required for structural integrity. Additionally, CNC technology minimizes material wastage, contributing to a more sustainable manufacturing process.

Another significant advantage of these machines is their speed. Traditional methods of producing drywall components can be labor-intensive and time-consuming. In contrast, a stud and track drywall forming machine can produce these components at a much faster rate, enabling construction projects to move forward more efficiently. This speed is crucial in today’s competitive construction environment, where project timelines are often tight, and delays can result in substantial financial losses.

Moreover, the durability of the products made with these machines is another key benefit. Metal studs and tracks are known for their strength and resistance to various environmental factors, including fire and moisture. This resilience not only enhances the longevity of the structures they support but also contributes to overall safety, making them a preferred choice among builders and architects alike.

As construction practices evolve, the future of stud and track drywall forming machines appears promising. Innovations are expected to continue, with the integration of smart technology, such as artificial intelligence and machine learning, to further enhance efficiency and productivity. These advancements could lead to predictive maintenance, where machines can self-diagnose potential issues before they become critical, reducing downtime and maintenance costs.

In conclusion, stud and track drywall forming machines play an essential role in modern construction, marrying efficiency with precision. Their ability to produce high-quality components quickly and sustainably positions them as indispensable tools in the industry. As technology continues to develop, we can anticipate even greater enhancements in machine capabilities, driving the construction industry toward a more innovative and productive future. For builders and contractors, investing in these machines is not just a choice but a strategic decision to stay competitive in an ever-evolving market.