The Rise of Stretch Bending Forming Machines in the Manufacturing Industry

In recent years, the manufacturing industry has witnessed a significant transformation driven by advancements in machinery and technology. One of the standout innovations is the stretch bending forming machine, which has emerged as a vital tool in various sectors. This machine offers unparalleled efficiency and precision, making it an essential component for Original Equipment Manufacturers (OEMs).

Understanding Stretch Bending Forming

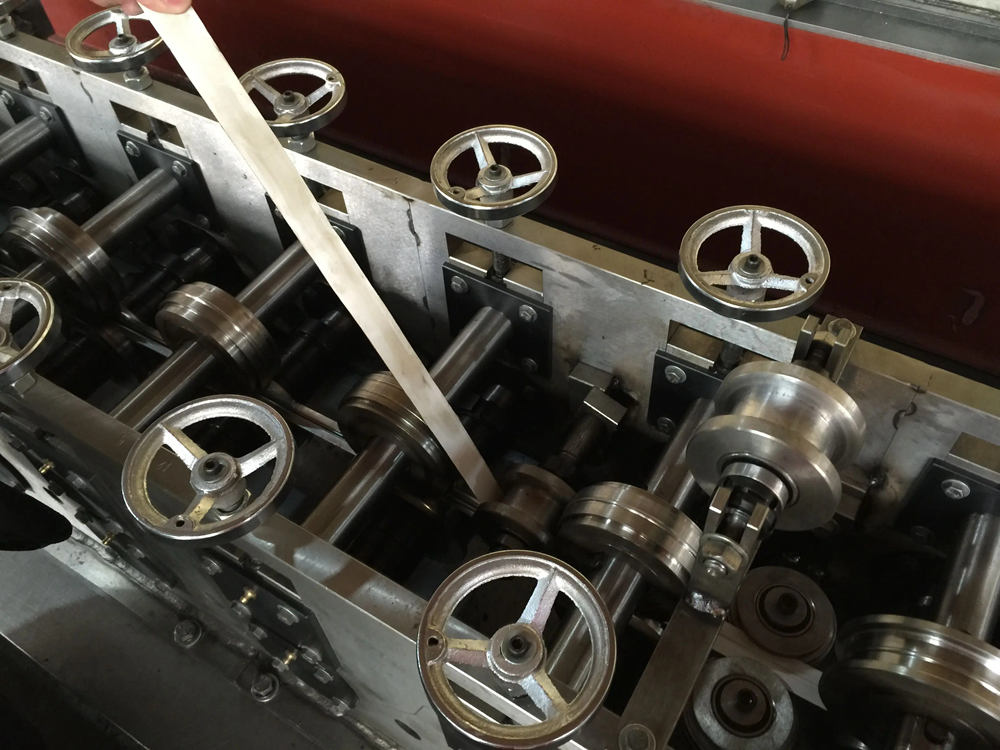

Stretch bending forming is a specialized manufacturing process that combines stretching and bending of materials, typically metals, to create complex shapes and components. The stretch bending forming machine utilizes hydraulic or mechanical systems to elongate the material while simultaneously bending it into a desired configuration. This process is particularly favored for its ability to produce high-quality components with smooth surfaces and minimal defects.

Key Features of Stretch Bending Forming Machines

Stretch bending forming machines come with a host of features that cater to the diverse needs of various industries. Primarily, they are designed for flexibility, allowing manufacturers to work with a wide range of materials, including aluminum, steel, and other alloys. Furthermore, these machines can accommodate different product sizes and shapes, making them suitable for automotive parts, aerospace components, and consumer goods.

Another notable feature is the level of automation incorporated into modern stretch bending machines. Many of these machines come equipped with advanced control systems that enable precise adjustments during the bending process. This leads to consistent product quality, reduces waste, and enhances overall productivity.

Applications Across Industries

The applications of stretch bending forming machines are vast, spanning multiple industries. In the automotive sector, for example, these machines are used to manufacture parts such as frames, brackets, and supports. The lightweight yet rigid structures produced through this process contribute to improved fuel efficiency and vehicle performance.

In the aerospace industry, stretch bending is crucial for creating components that require both strength and lightweight characteristics. The ability to produce complex shapes with minimal material usage positions stretch bending forming as a go-to solution for modern aerospace engineering challenges.

Additionally, the construction industry has started adopting stretch bending machine technology for fabricating steel beams and other structural components. The versatility and efficiency of these machines allow for quicker project turnaround times while ensuring high structural integrity.

The OEM Perspective

From an OEM perspective, the integration of stretch bending forming machines into production lines brings numerous advantages. Firstly, the reduction in material waste directly translates into cost savings, which is crucial in a competitive market. Secondly, the precision offered by these machines enhances product quality, leading to higher customer satisfaction and better market reputation.

Moreover, the automation features of stretch bending machines minimize the reliance on manual labor, thereby reducing human error and increasing production speed. This not only boosts overall efficiency but also allows OEMs to allocate resources more effectively, focusing on innovation and development rather than repetitive manual tasks.

Future Trends

As technology continues to evolve, the future of stretch bending forming machines looks promising. There is a growing emphasis on sustainability and the use of eco-friendly materials, prompting manufacturers to refine their processes. Enhanced computer-aided design (CAD) systems and simulation technology are enabling more precise engineering techniques, ensuring that the components produced are optimized for performance and sustainability.

Furthermore, the integration of Industry 4.0 concepts, including the Internet of Things (IoT) and smart manufacturing, will likely enhance the capabilities of stretch bending forming machines. These advancements will enable real-time monitoring, predictive maintenance, and data-driven decision-making, further increasing efficiency and reducing operational costs.

Conclusion

In summary, stretch bending forming machines are at the forefront of modern manufacturing, powering productivity and precision across various industries. Their ability to produce high-quality components efficiently makes them a preferred choice for OEMs. As technology advances and industries evolve, the role of stretch bending forming machines will only become more integral, paving the way for innovations that will shape the future of manufacturing. The investment in this technology is not just a trend; it is a strategic move towards sustaining competitive advantages in an ever-evolving market.