The Importance of Storage Upright Rack Forming Machines in Modern Warehousing

In today's fast-paced industrial environment, efficient storage solutions are paramount for businesses looking to optimize space and enhance productivity. Among various solutions, storage upright rack forming machines have emerged as an essential component in modern warehousing. These machines play a crucial role in the manufacturing of storage racks, which are fundamental for organizing goods and maximizing storage capacity.

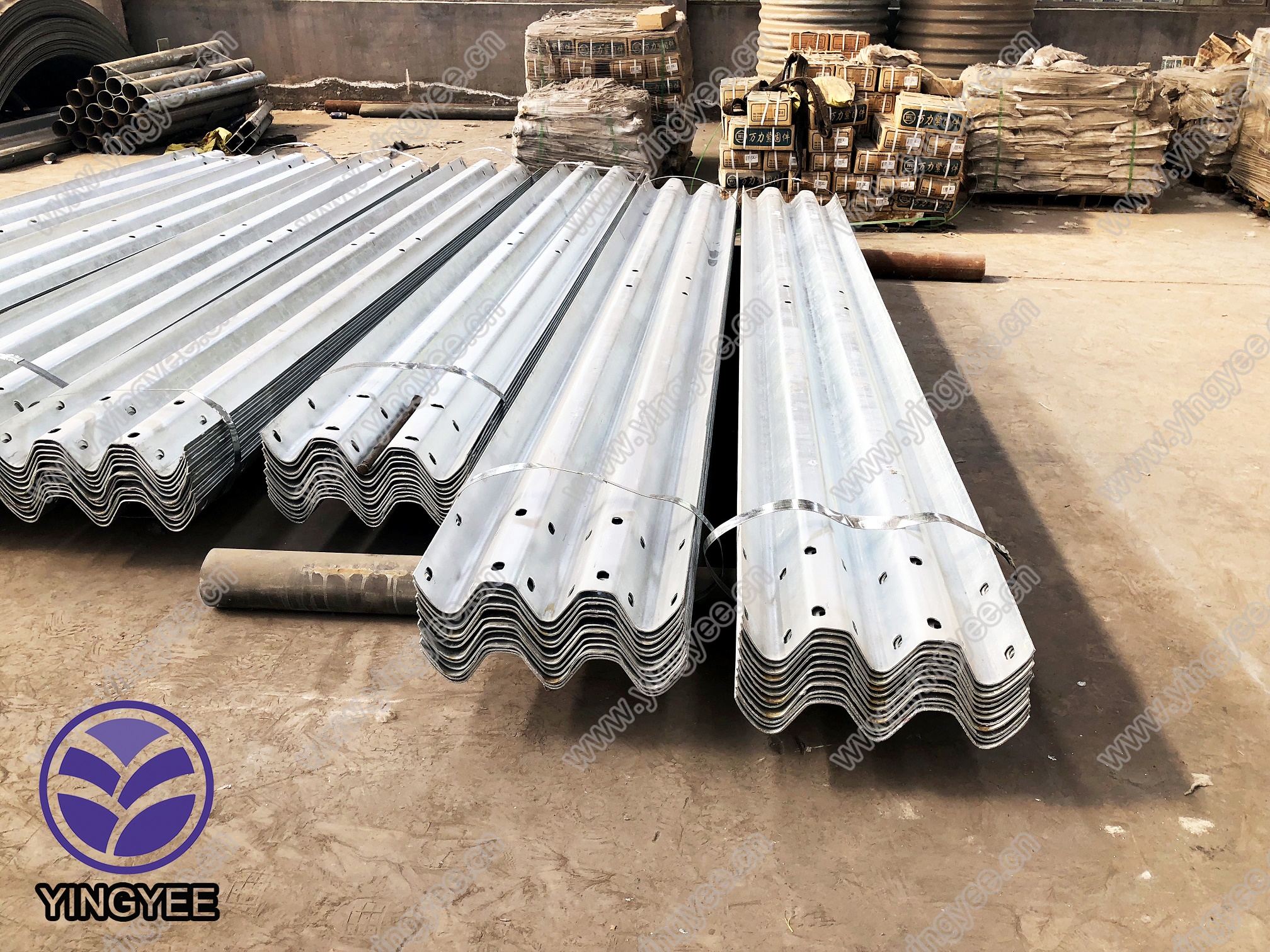

Storage upright rack forming machines are designed to produce the vertical components of storage racks, which are often the backbone of warehouse setups. These machines are engineered to bend, cut, and assemble metal sheets into upright structures that can support significant weight. By automating the manufacturing process, companies can ensure high precision and consistency in the production of racks, crucial for maintaining safety and structural integrity in storage solutions.

The advantages of using storage upright rack forming machines are numerous. First and foremost is the efficiency they bring to production. Traditional methods of fabricating storage racks can be labor-intensive and time-consuming. In contrast, these advanced machines require minimal human intervention, allowing for faster turnaround times and the ability to meet high demand without sacrificing quality. This swift production capability is essential for businesses that operate in sectors with fluctuating storage needs, such as retail, e-commerce, and manufacturing.

Moreover, the versatility of storage upright rack forming machines is another key benefit. They can be customized to produce various types of racks, including selective racks, drive-in racks, and pallet flow racks. This flexibility means that businesses can tailor their storage solutions to meet their specific requirements. For instance, drive-in racks are ideal for high-density storage, while selective racks allow for easier access to individual pallets. Being able to produce different styles of racks from a single machine streamlines the manufacturing process and reduces the need for multiple specialized machines.

Another significant aspect is the durability of the racks produced by these machines. The materials typically used are high-quality steel, which ensures that the racks are robust and capable of withstanding heavy loads. This durability not only extends the lifespan of the storage solution but also contributes to safety in the warehouse environment. Well-manufactured racks help prevent accidents caused by structural failures, thus protecting both the stored goods and the personnel working in proximity.

In addition to enhancing storage efficiency and safety, storage upright rack forming machines also contribute to cost-effectiveness in warehouse operations. By investing in these machines, companies can reduce labor costs associated with manual manufacturing processes. Furthermore, the increased production speed can lead to a quicker return on investment, enabling businesses to allocate resources more effectively.

Furthermore, as environmental consciousness increases globally, the use of storage upright rack forming machines aligns with sustainable practices. Many of these machines are designed to minimize waste during production, ensuring that materials are used efficiently. Additionally, reusable and recyclable materials such as steel are often the primary input, reducing the overall environmental impact of warehouse operations.

In conclusion, storage upright rack forming machines represent a significant advancement in warehouse storage solutions. Their efficiency, versatility, durability, cost-effectiveness, and alignment with sustainability goals make them an invaluable asset for modern businesses. As companies continue to seek out effective ways to optimize their warehousing processes, the demand for storage upright rack forming machines is likely to grow. Investing in these machines not only drives operational improvements but also positions businesses to adapt to the dynamic demands of the marketplace. As the warehousing industry evolves, embracing such technologies will be crucial for maintaining competitiveness in an increasingly complex logistical landscape.