The Steel Stud Making Machine Revolutionizing Construction

In the ever-evolving world of construction, efficiency and precision are crucial to meeting the demands of modern building projects. One of the innovations that have significantly contributed to this sector is the steel stud making machine. This specialized equipment has transformed the way steel studs are produced, offering remarkable improvements in speed, cost-effectiveness, and quality.

What is a Steel Stud Making Machine?

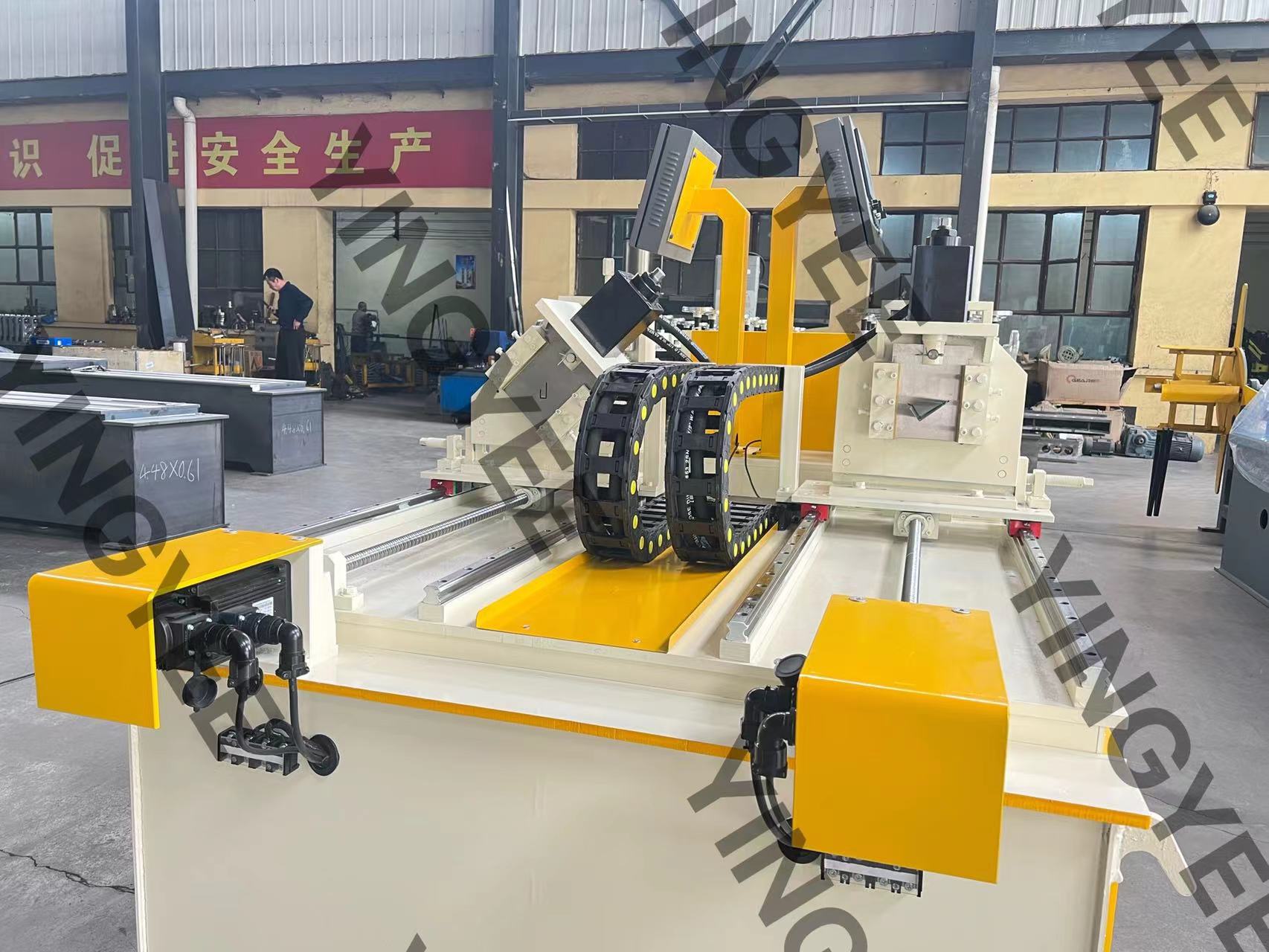

A steel stud making machine is a piece of industrial equipment designed to manufacture steel studs from raw materials. These studs are essential components used primarily in commercial and residential framing, where they serve as vertical supports for walls. The machine automates the production process, converting coil steel into finished studs with precise dimensions and specifications.

How It Works

The operation of a steel stud making machine involves several steps. Initially, steel coils are fed into the machine, which is equipped with a series of rollers and cutting tools. The machine flattens the coils and then shapes them into the required cross-section of the studs. Critical processes, such as punching holes for electrical wiring, can also be integrated, allowing for a comprehensive solution that minimizes additional labor.

Once the studs are formed, they are cut to the desired lengths and sorted for packaging. The automation of this process ensures consistency in quality and reduces the likelihood of human error. With high-speed capabilities, a single machine can produce thousands of studs in a day, catering to the demands of large-scale construction projects.

Benefits of Using a Steel Stud Making Machine

1. Increased Efficiency Traditional methods of producing steel studs can be time-consuming and labor-intensive. The steel stud making machine streamlines this process, significantly reducing production time. This efficiency translates to faster project completion times for builders and contractors.

2. Cost Reduction By automating the manufacturing process, labor costs can be reduced. Fewer workers are needed to operate the machines compared to manual production methods. Additionally, the precision of the machine reduces material waste, further driving down costs.

3. Superior Quality The consistency achieved through automation ensures that every stud produced meets high-quality standards. With precise measurements and uniformity, construction professionals can trust the integrity of the materials they are using, resulting in safer buildings.

4. Flexibility and Customization Modern steel stud making machines often come with programmable controls, allowing operators to adjust specifications with ease. Whether it’s changing the length, width, or even the type of stud being produced, these machines can adapt to varying project requirements, making them invaluable for companies that tackle diverse projects.

5. Scalability As the demand for steel studs grows, businesses can increase production capacity by adding more machines or upgrading existing ones. This scalability ensures that companies can meet fluctuating market demands without compromising quality or efficiency.

Conclusion

The steel stud making machine represents a significant advancement in the construction industry, addressing the traditional challenges of stud production with modern technological solutions. By enhancing efficiency, reducing costs, and ensuring superior quality, these machines are enabling builders and contractors to deliver projects that meet the high standards of today’s market. As construction practices continue to evolve, the role of steel stud making machines will undoubtedly expand, paving the way for even more innovative building solutions. For construction companies looking to stay ahead in this competitive landscape, investing in a steel stud making machine is not just an option; it is a strategic necessity.