Navigating the intricate world of steel construction requires not just skill, but also the right tools, with the steel purlin roll forming machine taking center stage in modern construction projects. This powerful piece of machinery has revolutionized the way purlins, essential structural components, are produced, offering unmatched precision and efficiency.

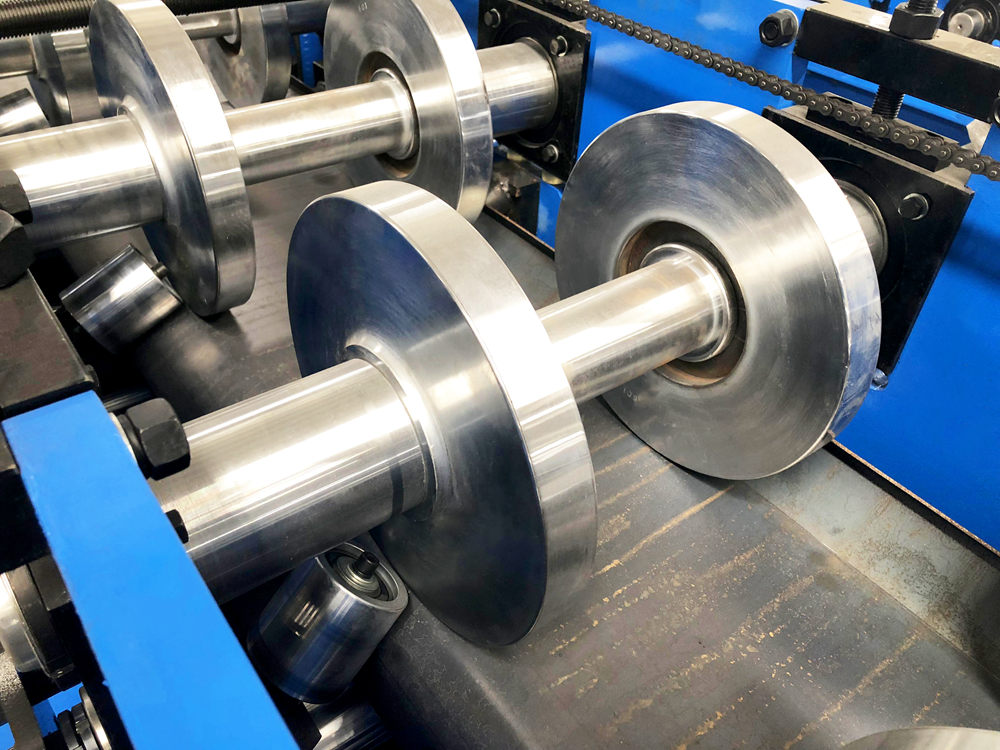

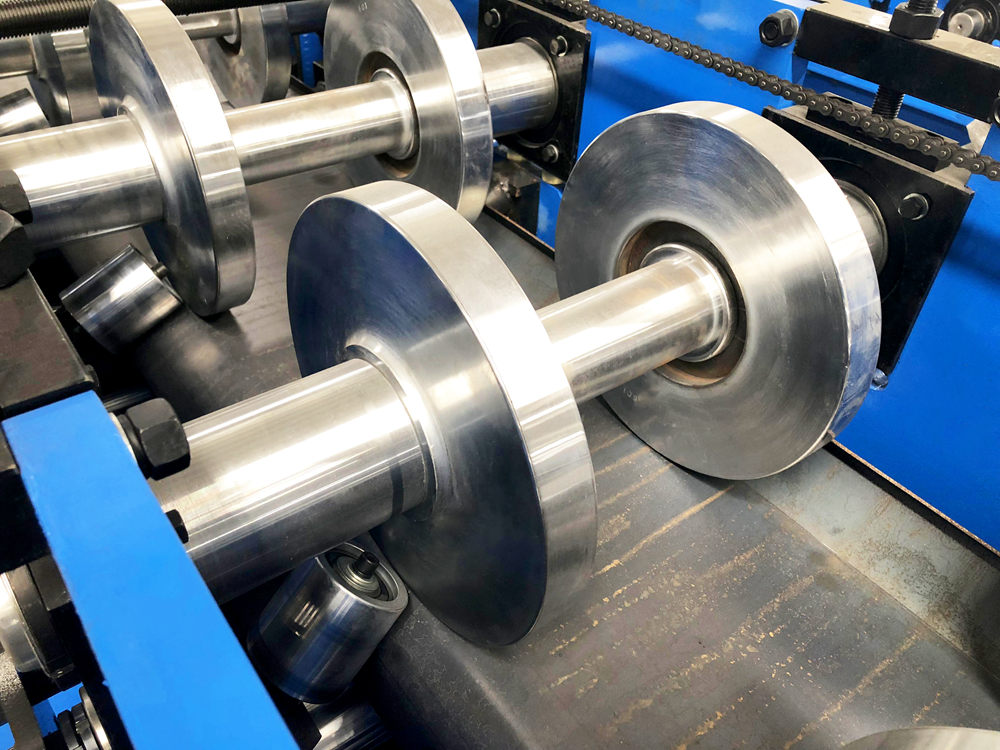

A steel purlin roll forming machine is designed to take galvanized or other metal sheets and transform them into purlins of various shapes and sizes, such as the common C and Z profiles used in roofing systems. This transformation is achieved through a series of meticulously arranged rolls, each contributing to a progressive change in the metal's shape. The beauty of this machine lies in its ability to handle a variety of thicknesses, catering to diverse structural needs.

Experience stands as a testament to the incredible benefits this machine brings. Companies that have integrated roll forming machines into their manufacturing process often report a significant reduction in material waste, a result of the machine’s capacity for precision cutting. In the past, the manual cutting and welding of purlins not only consumed time but also increased the likelihood of errors and material wastage. With roll forming machines, manufacturers can produce large quantities with consistent quality and minimal human intervention, a significant leap forward in manufacturing efficiency.

Expertise in the operation of a steel purlin roll forming machine can greatly enhance a company’s production capabilities. Skilled operators who understand the nuances of machine settings can adjust parameters to tailor the output according to specific project requirements. This adaptability is crucial as construction demands evolve. Continuous training and familiarization with the latest technological advancements in roll forming are essential for operators to maximize the machine's potential. The rise of software integration also allows for better control and monitoring, making these machines even more versatile.

steel purlin roll forming machine

Authoritativeness in the realm of steel manufacturing is closely linked to the quality and reliability of the equipment used. Over the years, steel purlin roll forming machines have become synonymous with reliability in structural engineering. They are crafted from robust materials to withstand the rigors of continuous operation while yielding precise outputs. Leading manufacturers of these machines often come with decades of experience and adherence to international standards, enhancing their credibility.

Trustworthiness in these machines does not merely come from the manufacturers’ claims but is backed by users’ testimonials and performance records. The choice of machinery can impact not just immediate project outcomes but also long-term structural integrity. Therefore,

ensuring that a roll forming machine meets stringent quality checks is paramount. Many companies opt for machines with certifications from recognized bodies, reinforcing client confidence in the durability and safety of the final product.

In conclusion, the steel purlin roll forming machine is a cornerstone of modern construction, bridging the gap between traditional methods and contemporary efficiency demands. A firm grasp of its capabilities and optimal usage can elevate any construction project, ultimately driving a more robust and cost-effective process. As technology advances, these machines are expected to evolve further, offering increased automation and integration with digital platforms, setting new benchmarks in construction practices around the globe.