Steel downpipe roll former making machines are revolutionizing the construction and building materials industry. These machines are an indispensable asset for manufacturers seeking to produce high-quality, durable, and aesthetically pleasing steel downpipes. The versatility and efficiency offered by these machines cannot be overstated, marking them as an essential tool in modern construction.

The primary function of a steel downpipe roll former making machine is to fabricate steel downpipes through a continuous process. This sophisticated equipment is engineered to transform flat steel sheets into fully formed downpipes, seamlessly shaping the material as it progresses through the roll forming process. The final product is a robust steel downpipe that can withstand the rigors of weather, proving to be both functional and long-lasting.

The roll forming process begins with feeding the steel sheet into the machine. This sheet is methodically guided through a sequence of hardened steel rollers. Each set of rollers applies pressure at strategic points, incrementally bending the steel sheet into a precise cross-section shape. This method ensures uniformity in production, resulting in consistent and exact specifications for each steel downpipe, which is critical for maintaining quality and ensuring ease of installation.

Investing in a roll former making machine represents a substantial commitment to quality and efficiency. These machines are tailored to meet the rigorous demands of industrial operations, offering unparalleled performance with minimal waste of materials. The high precision of these machines means manufacturers can produce large volumes of product within a minimal time frame, thereby meeting increased demand without sacrificing standards.

The expertise involved in operating a steel downpipe roll former requires specialized training. Operators must be adept at understanding the intricacies of the machine's mechanics, capable of making adjustments to speed, pressure, and other parameters to ensure optimal performance. Moreover, ongoing maintenance is crucial to ensure the longevity and reliability of the machine. Regular inspections and servicing by certified technicians help prevent downtime and extend the machine’s operational lifespan.

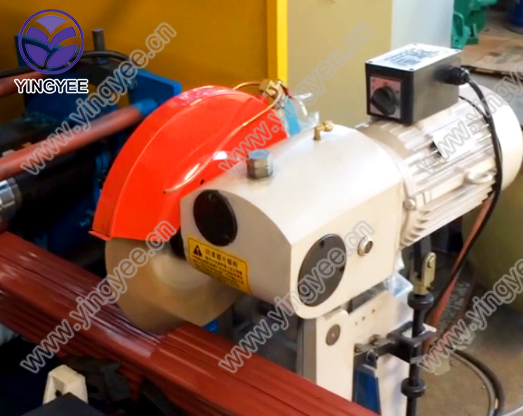

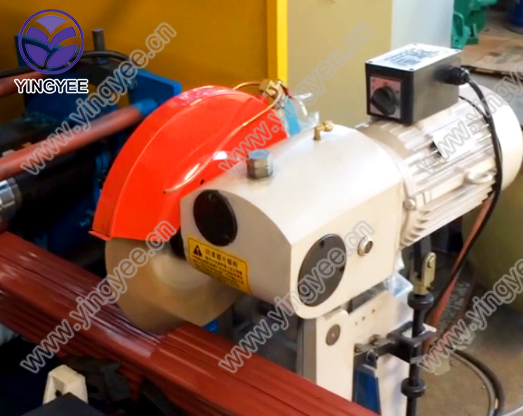

steel downpipe roll former making machine

In terms of design flexibility, these machines offer a high degree of adaptability. Manufacturers can cater to custom orders by adjusting the roller dies to produce downpipes of varied dimensions and profiles. This level of customization is invaluable in today’s market, where specific architectural requirements must be met without delay.

Furthermore, steel downpipe roll former making machines are synonymous with sustainability. The efficiency in material use aligns with global objectives to reduce waste and promote environmental responsibility. In addition, the use of steel — a recyclable material — in construction is a positive step towards sustainable building practices.

As the market continues to expand, the role of steel downpipe roll former making machines is set to grow even more crucial. Companies that invest in this technology position themselves as leaders in the industry, capable of responding to evolving market trends with flexibility and confidence. The integration of such advanced machinery not only ensures a competitive edge but also solidifies trust and authority among clients and partners, assuring them of a commitment to quality and innovation.

In conclusion, the deployment of steel downpipe roll former making machines is a definitive strategy for any construction material manufacturer aiming to enhance production capabilities and product quality. Committing to such technology indicates an adherence to the highest professional standards, fostering expertise and reliability in a rapidly advancing industry.