Exploring the Standing Seam Rolling Machine A Revolution in Metal Construction

In the modern construction and architecture landscape, innovative machinery plays a pivotal role in enhancing efficiency, precision, and quality. Among the various types of machines that have revolutionized metal roofing and siding applications, the standing seam rolling machine stands out for its unique design and functionality. This article delves into the intricacies and benefits of standing seam rolling machines, highlighting their importance in today's manufacturing processes.

Understanding Standing Seam Roofing

Standing seam roofing has emerged as a popular choice in both residential and commercial buildings due to its durability, weather resistance, and aesthetic appeal. The term standing seam refers to the vertical legs of the metal panels that interlock, creating raised seams. These seams are typically higher than the panel's flat area, enabling effective water drainage and protection against leaks. The design allows for thermal expansion and contraction, making it suitable for diverse climates.

What is a Standing Seam Rolling Machine?

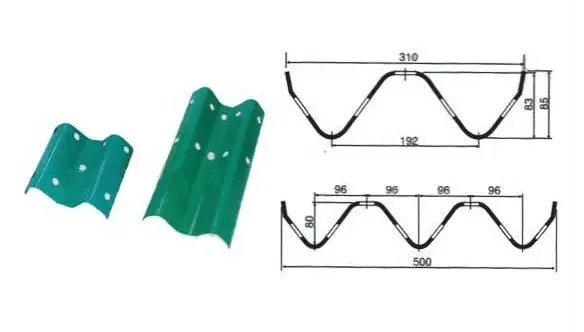

A standing seam rolling machine is a specialized piece of equipment used to fabricate standing seam metal roofing panels from coils of metal. The machine shapes and forms the metal into the desired profile while also creating the necessary seams. This process involves several steps, including feeding the metal coil into the machine, which then progressively bends and shapes the metal until it reaches the final standing seam profile.

How Does it Work?

The operation of a standing seam rolling machine can be summarized in a few key stages

1. Feeding Large coils of metal sheets, typically aluminum or galvanized steel, are loaded onto the machine. 2. Forming As the coil passes through a series of rollers in the machine, it is gradually shaped into a standing seam profile. The precision of this process is crucial, as it ensures that the seams are consistent and meet industry standards.

3. Seaming Once the panel is formed, the rolling machine creates the raised seams that are characteristic of standing seam roofs. These seams, crucial for water resistance and structural integrity, are pressed firmly to ensure a tight fit.

4. Cutting Finally, the machine cuts the panel to the desired length, completing the process. The panels produced can then be transported to the construction site for installation.

Advantages of Using a Standing Seam Rolling Machine

1. Efficiency and Speed The automation provided by rolling machines significantly speeds up the production process. This efficiency allows contractors to complete projects more quickly and effectively.

2. Consistent Quality Precision engineering means that each panel produced is uniform, minimizing the risk of errors and enhancing the overall quality of the roof.

3. Customization Many modern standing seam rolling machines offer customization options, allowing manufacturers to create panels of various lengths, colors, and finishes to meet specific project requirements.

4. Material Conservation By optimizing the amount of metal used during production and minimizing waste, these machines contribute to more sustainable manufacturing practices.

5. Enhanced Performance The design of standing seam roofs produced by these machines provides superior performance in terms of waterproofing and durability, making them an ideal choice for a wide range of applications.

Conclusion

Standing seam rolling machines are integral to the efficient and effective production of standing seam metal roofing systems. With their ability to enhance productivity, ensure consistent quality, and support customization, these machines are changing the landscape of metal construction. As the demand for durable and sustainable building materials continues to rise, standing seam rolling machines will undoubtedly play a crucial role in shaping the future of the construction industry. By investing in advanced technology and machinery, manufacturers can not only streamline their operations but also contribute to a more sustainable and resilient built environment.